News

2014 Volkswagen Jetta TDI MT: Clutch overhaul at 90000 km odo

The clutch now feels feather-light, with the gearshifts remaining smooth as before.

BHPian vishy76 recently shared this with other enthusiasts.

Overhauling a German Car (Part 1)

There’s this advice that goes around in car circles (specifically on Team-BHP). It says “Don’t sell off your 5-year-old car just yet, spend on it and keep it”. There’s an entire thread on this topic and a number of other threads, posts and individual decisions have stemmed from it. However, there’s one question that I am sure everyone had while going through it, and it’s this: How hard can it be? How hard can it really be to give your car a midlife overhaul? Where should you have it done? What should be done? When should it be done and how do you figure out who’s the right guy to do it for you?

Answering all of those questions (hopefully) would be these threads. Most of you might already be knowing my prodigal son, a 2014 Volkswagen Jetta 2.0 TDI manual (link). He’s been a very mischievous lot, troubling me many times and oft after the 4th year mark and handing me a couple of heart attacks (read: bills amounting close to 6 digits). In spite of all this, I have accepted him for the better.

Yes, he’s not as reliable as my neighbour’s Corolla, not as modern as my uncle’s Octavia and his elder Czech sibling (whose name I shall not take due to vocab reasons) was a far more popular kid in school. All said and done, however, he’s become a member of the family now. I do get the occasional taunts from friends asking me to sell him off and get something more reliable, but I guess we all have an irrational side and my love for him (for cars as a whole in fact) is nothing but this irrationality shining through.

With all this melodrama out of the way, it's time to get to business. I will split this saga up into bits and pieces to make it easier to understand. These threads will embody every aspect of overhauling wear and tear items in a car. The clutch, suspension, mounts and even a few bonus items like the air conditioning will be covered. All of these components will first be explained in detail so that one can take away a lot more than just high-res images of car parts from this thread.

Lastly, let this also be a tribute of sorts to the VW Jetta Owners group which has taught me a lot about this machine in great detail. This is my way of giving back to the Jetta community for all they have done so far for me.

Chapter 1 – Clutch, Flywheel

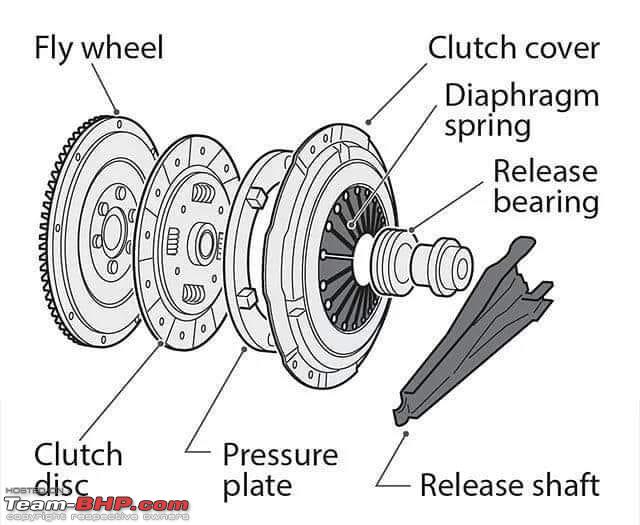

The automotive clutch is one of the most essential components of a manual tranny (and even certain automatics), yet it has remained unchanged largely over the years. The most radical change to a clutch that has been brought about by most carmakers is the use of hydraulics to manipulate it instead of the good old-fashioned cable. Here’s a diagram of the automotive clutch:

Let me go through what happens here briefly:

- When you press the clutch pedal, the fork is pushed against the clutch release bearing which in turn pushes on the splines (the teeth like structures) on the pressure plate.

- The pressure plate, friction plate and flywheel are all in contact ideally when the clutch is not pressed. However, when it is, the splines on the pressure plate are pushed inwards while the diameter of the plate expands outwards

- This allows the friction plate to move away from the flywheel and lose contact with it, thus disengaging the gearbox input shaft (passing through the centre of all these discs) from the rest of the tranny and allowing you to shift gears

This explanation isn’t a very concise one, so here’s a simple video showing how a clutch works. Will make things much simpler to understand.

Points of Failure

An automotive clutch can age (and consequently fail) in the following ways:

- The pressure plate fingers go weak. This is the earliest symptom of a weak clutch usually. The end result is that the pedal goes hard. You have to apply a lot more effort to have the fingers move inwards since the plate itself has lost elasticity. Another symptom of a weak pressure plate is juddering when getting off from a standstill. This typically results from bent fingers on the pressure plate. As the release bearing slowly mates with them on releasing the pedal, the fingers contact it unevenly leading to juddering.

- The second reason for changing a clutch is slippage. The friction plate and flywheel when in contact should be almost perfectly “slippage-free” and transfer all power through to the input shaft. However, age causes the material on the friction plate to wear and eventually give up. The end result is power loss. You will often notice the engine revving in gear but not the same increase in speed or even sudden changes in engine speed spontaneously in gear under load. This is typical of a bad friction plate

- The last (and usually the least occurring) reason is the clutch release bearing (CBR) failing. The bearing itself usually doesn’t go bad but can start making noise (characterized by a whine which disappears when you engage or disengage the clutch)

With the basics covered, I will move to the Jetta’s clutch.

The Jetta’s clutch expectedly bins the cable and fork system, opting for a more modern hydraulic setup. A set of three cylinders generate, multiply and transfer pressure from the pedal in the cabin down to the bearing in the gearbox housing. These are:

Master cylinder: Sits above the clutch pedal in the cabin and converts the driver’s pedal movement into hydraulic pressure

Special thanks to BHPian akshay_rebel for clicking pics of his car's master cylinder:

Primary slave cylinder: Sits above the gearbox housing and helps in transferring and maintaining the same pressure across the circuit down to the CBR

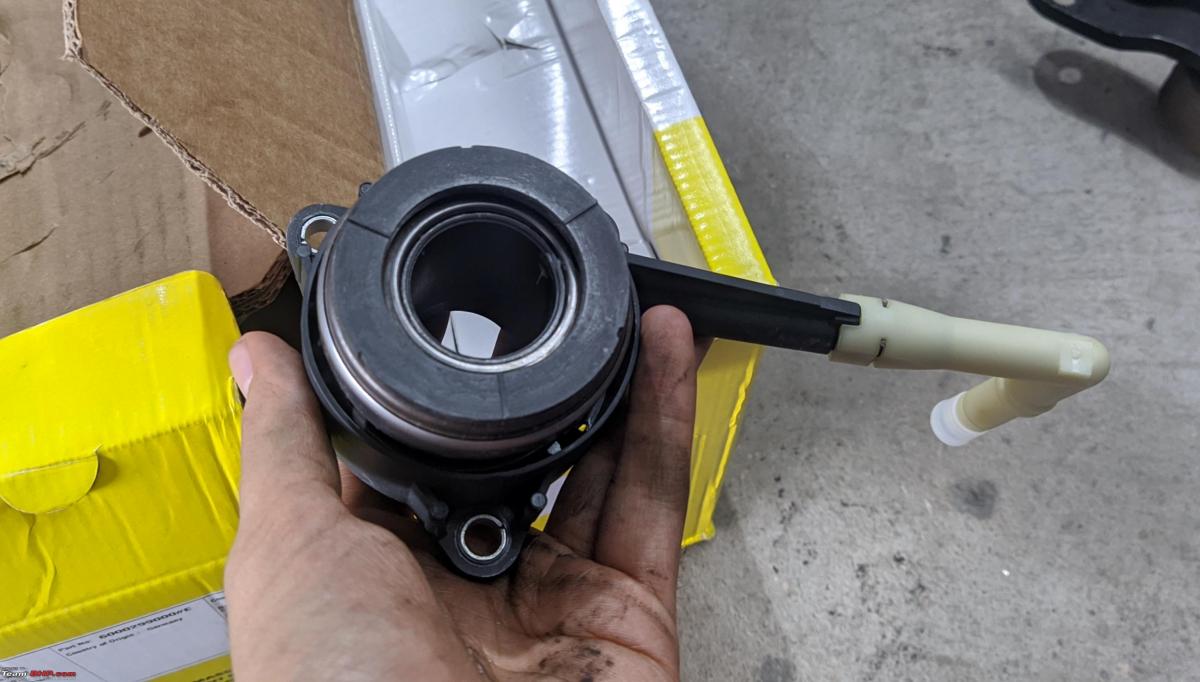

Concentric slave cylinder cum CBR (clutch release bearing): The clutch setup mentioned above is quite common across most cars with a hydraulic system. However, it changes here. Instead of having a simple fork and release bearing (which even the Polo/Vento have I believe), the Jetta gets another slave cylinder with an integrated release bearing.

The entire face of the slave with an integrated bearing moves inwards and outwards due to hydraulic pressure.

Flywheel

Theoretically, the simple job of a flywheel is to smoothen out the pulses that occur as a result of the upward and downward motion of the pistons (which obviously doesn’t happen all at once). It provides momentum to the crank and ensures seamless power delivery, apart from being a component of the clutch system in a manual.

There’s not much that can go wrong with a “solid”, “single mass” flywheel. It’s essentially just a precisely weighed disc that bolts to your crank and spins with it. Yes, there is the odd occurrence where the teeth on its circumference (that mesh with the starter motor pinion) wear out, but that’s about it. A single mass flywheel (SMF) can be used for 2-3 clutch changes as well since it only needs to be skimmed if the mating area with the friction plate has grooves.

Unfortunately, the automotive industry found a way to overcomplicate this simple component too and thus came the DMF (Dual Mass Flywheel). The dual mass flywheel is essentially composed of two masses (as the name suggests) with dampening springs in between.

What this does is absorb drivetrain shocks (jerks while pressing and letting go off the clutch) better and results in lesser harshness and vibes going down the gearbox input shaft. Another reason for adopting DMFs is that manufacturers can cheapen out on GB components too. Since the GB won’t see a lot of shocks going through it thanks to this flywheel, lighter and cheaper synchros can also be used.

This is the case with the MQ350 (02Q) GB in the Jetta. Instead of using heavier brass synchro rings, it makes do with steel synchros. There have been several cases of 6-speed TDI owners reporting blown gearboxes after switching to SMFs, thus proving that VW did have a lot to save by using this flywheel.

Failure points for a DMF

A DMF (as expected) has a few more failure points as compared to its contemporary sibling. Here they are:

- The dampening springs between the two masses can seize, essentially rendering the flywheel useless. This can cause vibrations and a very loud knocking sound to emanate from the gearbox side

- DMFs and water wading are two things that never get along. Unfortunately, my car was a victim of this. Water can cause the innards of the DMF to corrode and the torsional springs to seize again. The result is again clutch chatter and vibrations when letting off the clutch

This video also documents how to check for a bad DMF. Every DMF has a certain amount of play in it before the torsional springs kick in and restrict movement. This play however shouldn't be excessive and nor should there be any upward and downward play between the two halves

Continue reading BHPian vishy76's VW Jetta clutch overhaul for more insights & information.