News

Nissan's CMF architecture to be shared with Renault

Well over a year ago, Japanese automaker Nissan announced the Common Module Family (CMF), a car making architecture that was the automaker's answer to parts and platform sharing programs such as Volkswagen's MQB and Daimler-Benz's MFA. While the Nissan CMF architecture was initially said to include only Nissan car models, the car maker's deepening alliance with French automaker Renault has meant that the CMF architecture will now be used on Renault car models as well.

An official announcement from Renault-Nissan has arrived and from the looks of it, the CMF based cars will begin seeing launches as early as the end of 2013. The first cars on the CMF platform will be those from the Nissan range. The next generation versions of the Nissan Rogue, Qashqai and the X-Trail will embrace the CMF architecture by the end of this year. By the end of next year, Renault will join the CMF fold with replacement models of cars such as the Espace, Scenic and Laguna.

Initially, the CMF architecture will be used on compact and large cars in the Renault-Nissan range. In due course of time, the entire gamut of cars sold by the global car making alliance will embrace the new architecture.

Here are the high points of the Common Module Family (CMF), as detailed in a presser released by the Renault-Nissan alliance,

- CMF will generate an average 30-40% reduction in entry cost per model and 20-30% reduction in parts cost for the Alliance.

- CMF will be deployed across 5 continents in more than 10 countries through 2020.

- The first deployment of CMF, for the compact and large car segments, will cover 1.6 million vehicles per year and 14 models (11 Renault group + 3 Nissan).

What is the CMF architecture all about?

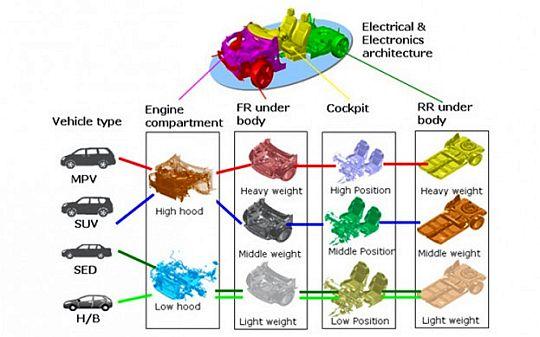

The CMF architecture involves heavy parts sharing across car segments. This sharing will be achieved by a kind of standardization. The CMF architecture divides car into 5 distinct elements, known as modules. These elements are: engine compartment, cabin, front under-body, rear under-body and electronics. These modules can be mixed and matched across segments, which means that the CMF architecture goes a step further than mere platform sharing. In fact, the CMF architecture is capable of underpinning cars across multiple platforms.

For instance, a diesel engine (in this case the 1.5 liter K9K unit) powering a small car such as the Micra can also be used in an SUV (say the Nissan Duster or the Nissan Juke). While the engine will be mounted low in the Micra, it will be mounted high in an SUV such as the Juke. The overarching idea is to create a standardized range of parts that can be used in various configurations across a range of cars. Such standardization will give the Renault-Nissan car making alliance significant cost benefits.

These cost benefits are expected to be passed on to the car buyer. So, the cars in the Renault-Nissan range are expected to get cheaper than before. Looking at these cost savings from a different perspective, cars based on the CMF architecture could retain their current price levels, albeit with a higher level of equipment/features on offer. On the whole, a big sales boost is what the Renault-Nissan alliance is looking at, by employing the CMF architecture across its car range.

Notably, the CMF architecture will be integrated into the Renault-Nissan alliance's common manufacturing plan, meaning that this architecture will support manufacturing facility sharing between the two car makers. Joint manufacturing facilities are already giving the Renault-Nissan alliance attractive cost benefits and the integration of the CMF architecture could further strengthen this approach.

One such joint manufacturing facility is right here in India, at Oragadam, off Chennai. The Oragadam factory of Renault-Nissan plays host to a range of cars from both the automakers. Eventually, India (Already a vital cog in Nissan's export strategies) is expected to be a major center of car making using the CMF architecture.

.jpg)