News

Know what’s inside a torque converter automatic transmission

A torque converter is commonly referred to as TC or torque converter automatic. It is nothing but a clutch that does not need a clutch pedal to be operated.

BHPian Indian2003 recently shared this with other enthusiasts.

Many of you know you have a torque converter in your automatic transmission but only a few know what is inside. The torque converter is a piece of complex engineering. The guy who invented the auto box must have loved working with liquids.

I went over to the trade school I worked at in 2009. A model of my car's torque converter was made. This, so the students can see inside and learn how things work.

The first-year students made it themselves with some guidance.

These kids are tired of school and instead of dumping them and giving up, they are given a new chance to pursue their hobby which is automobiles. They have 4 hours of theory and 4 hours of practical work every day. At the end of the year, they have to pass an exam and then go on a 2-year apprenticeship at a workshop. Another exam later, they become qualified master mechanics and different companies wait in line to snap them up.

All but 1 passed in my group in 2009 and today have well-paid jobs, some of them running the workshops of different car and truck dealers. Most of them continued to work at the same workshop where they were once an apprentice.

The torque converter from the outside

The insides

The lock-up gear, that is a direct connection between the motor and the drive axles.

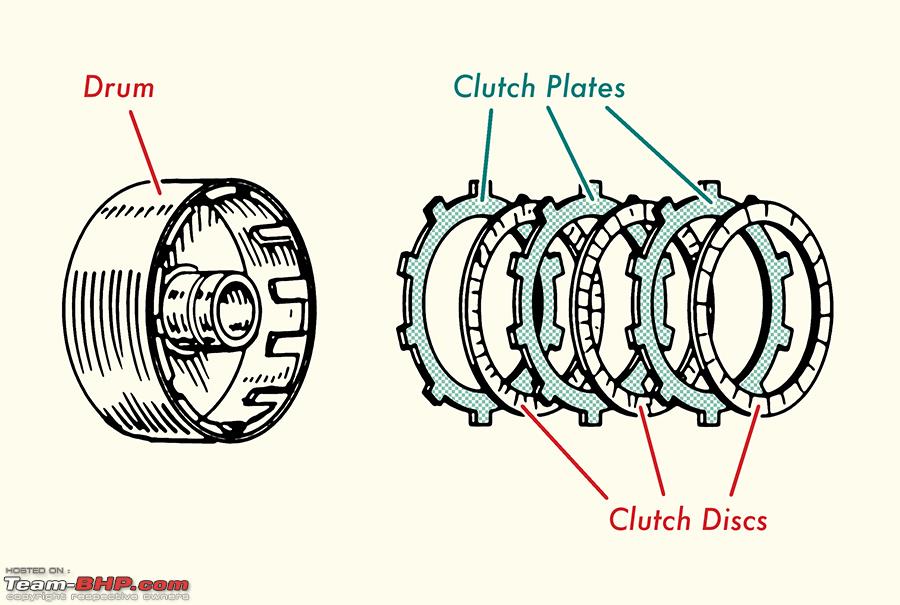

Torque converters have some sort of friction plates. In mine, there was a friction disc. All automatic boxes have friction plates in housings, as in motorcycles. The lock-up disc has no friction material and is locked mechanically by the disc.

The AT is not a fit-and-forget unit. I have heard car salesmen recommend automatic transmissions as maintenance and clutch free but that is a lie or they don't have a clue as to what they say.

I was at a Suzuki dealer a few months ago to look at the Ignis for a member of this forum. I asked about the size of the engine, does it have side airbags, how many airbags does the car have, and is the 4X4 system a traditional mechanical system or is it a Haldex system.

The guy did not have a clue. He thought the Ignis had a 3-cylinder engine with enough power. He was sure there were 2 and his partner said there must be side airbags because the A-pillar was very big. All he could say about the 4X4 system was that it was very good.

Here's what BHPian Guna had to say about the matter:

Automatics based on TC also have planetary gears. The torque converter is just the part which is playing the role of the clutch.

Here's what BHPian Madrasin_selvan had to say about the matter:

The torque converter in an AT is used to maintain the fluid coupling between the engine and transmission. This fluid coupling helps in the transfer of power from one shaft to the transmission shaft.

The transmission shaft leads into the automatic transmission where the planetary gear sets are placed. For a 6-speed transmission, two planetary gear sets are working in combination, while for an 8-speed, you need one more gear set and so on. The clutch discs help in moving the gear sets, while the Transmission Control Module sends signals according to the throttle input and driving conditions. The movement of the clutch discs is operated through the valve body (the black color part) or sump placed at the bottom/side of the AT.

The torque converter automatic gearbox is one big marvel of engineering. The tolerances involved in the AT are so minuscule that even a 0.1mm change can lead to oil leakage and performance loss.

In short > throttle Input > Transmission Control Module > sends signal through actuators to valve body > releases fluid to engage or disengage the clutch > planetary gear set moves to increase or decrease the speed.

Here's what BHPian zeng had to say about the matter:

A typical complete Automatic Transmission consists of various individual sub-assemblies like:

- Standalone Torque Converter aka fluid coupling which receives mechanical power from engine crankshaft/engine flywheel via external ring gear being part of Torque Converter assembly.

- It is a fluid coupling in itself with or without lockup clutch component transferring power from engine flywheel to input shaft of epicyclic gear set(s) adjacent and outside of Torque Converter assembly.

- Torque Converter output shaft would receive mechanical power from fluid coupling (with no lockup clutch in operation) or from lockup clutch set (as and when lockup clutch is put into operation), hence, splined to and transfer mechanical power to the input shaft of epicyclic gear set(s).

The above 3 sub-sets of components is housed internally in one complete housing/assembly as pictured.

- Epicyclic gear set(s) whose input shaft receives power from Torque Converter Output shaft.

- This incoming power is controlled and directed by sub-assemblies within Automatic Transmission Housing like Clutch/piston set assemblies for varying speeds of 1,2, R, N etc., and control valve and its actuator system.

The above 2 Sub-sets are housed internally within the transmission housing proper adjacent and bolted to Torque Converter Housing/assembly.

- In varying transmission speeds of 1, 2, R, N, etc., the output shaft of the epicyclic gear set delivers mechanical power to the propeller shaft(s) in the case of a RWD or to Front axle half-shafts in the case of FWD.

Just my 2 cents.

Here's what BHPian KSingh had to say about the matter:

One of the simple and best explanations of torque converter I came across is given here.

The coupling between the drive and driven shaft is done through the turbine and impeller (fluid coupling). The torque converter consists of a turbine, a pump/impeller, a stator and a lock-up clutch.

In simple words, the fluid coupling can be imagined as two table fans kept facing each other and when one fan is operated (by an electric motor) other will start rotating without any power input.

Operation

Stall

The impeller or pump receives the mechanical energy produced by the engine, but the turbine does not rotate because the brakes are still applied.

Acceleration

The brakes are no longer applied and the acceleration pedal is pressed, as a result, the impeller rotates faster and produces torque multiplication working in conjunction with the turbine.

Coupling

At this stage, the vehicle speed has increased, hence, the turbine reaches approximately 90% of the speed of the impeller and the torque multiplication ceases. Modern torque converters use a lock-up clutch to reduce the energy losses within the coupling fluid by mechanically locking the turbine to the impeller.

Here's what BHPian SS-Traveller had to say about the matter:

Thanks for bringing this topic up. Too often, we find people referring to automatic transmissions as torque converter automatic (TC) vs CVT vs DSG vs AMT.

As explained above, the torque converter is nothing but the clutch, without requiring a C-pedal to operate it. Now, what is commonly referred to as a TC or torque converter automatic (e.g. the Ciaz / XL6 4-speeder), is an automatic gearbox running a set of planetary gears (which is a whole different topic to explain), connected to the engine through the torque converter.

Just to clarify, the Baleno / Glanza has a CVT (constantly variable transmission) gearbox, BUT it is connected to the engine through a torque converter as well! So technically speaking, both the XL6 and the Baleno automatics are TC automatics - except that the gearbox is planetary in the former, and CVT in the latter.

Ring gears are never welded, if I may be allowed to point out a specific technicality again - they are press-fitted after heating to a certain temperature. Once it cools and shrinks, it grips the flywheel firmly. Broken ring gear teeth will necessitate replacing the outer toothed ring only, not the entire unit.

Check out BHPian comments for more insights and information.

(1).jpg)