News

Types of coolants & debunking myths about grades and colours

It’s a fluid that is second only to engine oil in an internal combustion engine, yet is ignored most of the times.

BHPian vishy76 recently shared this with other BHPians.

Coolants and their types

This thread has been jointly compiled with BHPian Vigsom. Thanks to him for the expert inputs!

Coolant. A very simple yet crucial component in the era of modern (comparatively) high compression ratio engines. It’s a fluid that is second only to engine oil in an internal combustion engine, yet is ignored most of the times.

In the olden days, the word “coolant” simply implied “water”. Water with its high specific heat capacity (which basically means it needs a lot of heat in comparison to other liquids in order to raise its temperature by a specific amount) was perfect for car radiators in theory. The high specific heat capacity ensured it could transfer a large amount of heat easily from the engine block to the radiator. There were two downsides or shortcoming however:

- Firstly, water has a comparatively high freezing point of 0 degrees Celsius. This means it would freeze and block cooling system pipes and radiators in the winters.

- Secondly, water would react with the iron present in the engine block and form rust. This rust would eventually choke the radiator over time too. This would also impact the heat transfer (by forming oxides) and cause issues in both the radiator and engine block.

In order to overcome the former, alcohol was added to water and used as a coolant. Alcohol formed a mixture with water which would lead to a “depression” in freezing point, thereby preventing freezing. Unfortunately, the boiling point of alcohol was much lower than water, which would mean the resulting mixture would also boil very early (around 80 degrees Celsius), needing frequent top-ups.

Inorganic Acid Technology (Ethylene Glycol)

The writing was on the wall. There was a need for a liquid that would offer the depression in freezing point normal alcohol such as ethanol would, yet not boil over early like the former did when it formed a mixture with water. The answer to this predicament was (and still in many cases) is ethylene glycol. Ethylene glycol-based coolant is called “Inorganic Acid Technology based coolant” because it contains silicates and phosphates in order to comply with the metal parts in a cooling system.

An Ethylene Glycol and water mixture (in a 60:40 ratio) would freeze at -45 degrees Celsius (thus beating even alcohol in this regard) and boil at well over 100 degrees Celsius. This means the fundamental issues of early freezing (due to inherent properties of water) and early boiling (due to properties of alcohol) stood solved. Ethylene Glycol however brought about two other minor headaches:

- Firstly, its chemical composition meant it would disintegrate and lose its properties, thus requiring a change every 2-3 years

- The more lethal property of Ethylene Glycol was that its disintegration would exponentially increase its electrical conductivity. An electrically conductive liquid when in contact with the iron present in the engine block would be the perfect recipe for rust formation

Thus, started the hunt for a liquid which would further last a lot longer. This is not to say that Ethylene Glycol isn’t used in today’s cooling systems. The green coolant used by many manufacturers even today is ethylene glycol. It does a better job of controlling rust formation in older engines with iron blocks and has additives in the form of silicates and phosphates.

Organic Acid Technology (OAT)

Organic Acid technology was the answer to the previous bottleneck. Organic Acid Technology ensured that the coolant itself was composed of non-degradable chemicals (thus addressing the fundamental issue that IAT brought to the table), while also being silicate, borate and nitrite free, further preventing any chances of increase in electric conductivity with ageing and the rusting that followed. The biggest ace up its sleeve however was the fact that OAT offered superior protection to aluminium under high temperatures, a property that would exhort many manufacturers to shift from IAT to OAT.

The G12 and G12+ coolants (pink coolant) used by Volkswagen are OAT coolants. Both are phosphate, amine and phosphorous free. The only issue with OAT, was that it was a step back in corrosion protection as compared to (perfectly functional) IAT.

Hybrid Organic Acid Technology (HOAT)

Simply mixing the two coolants (IAT and OAT) would not be the solution (as expected) and lead to an even more corrosive mixture. However, the final breakthrough in coolant technology was brought about by HOAT or Hybrid Organic Acid Technology. Theoretically, it is impossible to mix IAT and OAT (as mentioned before), but HOAT allows both to work in tandem, while offering excellent rust protection, very high B.P and low F.P and lasts beyond 5 years (up to 1.8L km in some cases).

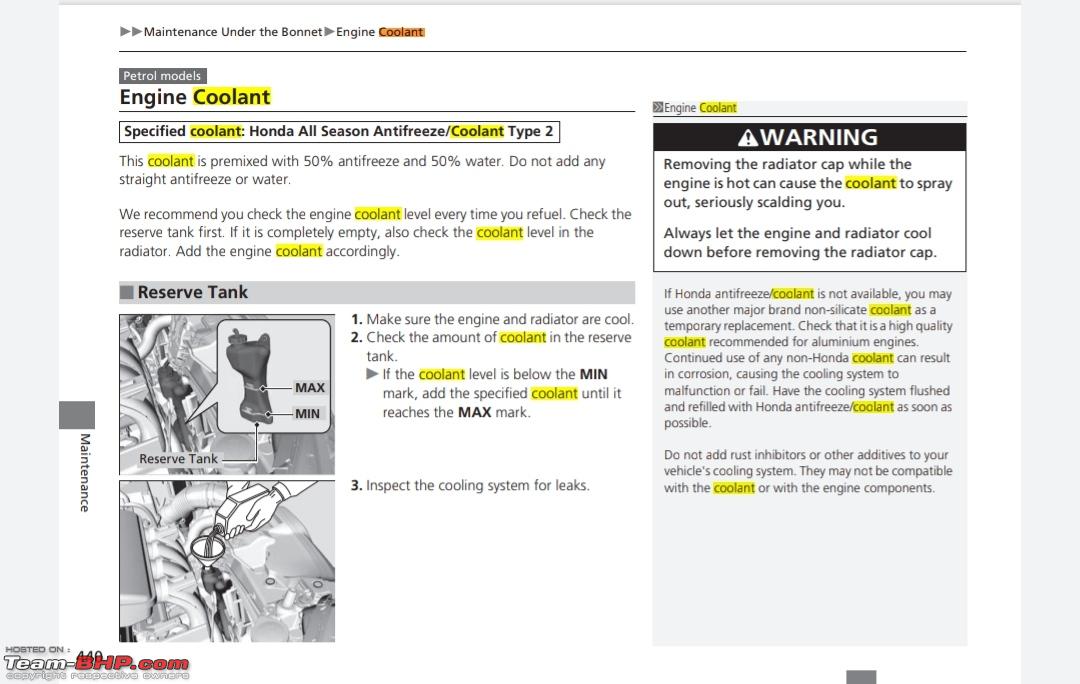

HOAT is used by Volkswagen (G12++ and G13) and is also reverse compatible with OAT (G12 and G12++ that I mentioned before). Honda also uses HOAT (blue coolant).

Debunking common myths associated with coolant colours and grades

With all the types of coolants listed down, I will end this short post by shedding light on some common myths and trying to clear them.

- It is NOT advisable to mix two different coloured coolants unless you are sure that they are both OAT, IAT or HOAT. As I mentioned before, mixing different coolant types with each other might increase chances of corrosion and cause disaster. It is always thus advisable to put distilled water instead of mixing coolants having different colours.

- Putting a coolant colour that hasn’t been recommended in your car can have many ill-effects in the long term.

Taking an example of a VW TDI here. VW recommends G12 OAT coolant be poured in. I pour in green coolant (IAT). The TDI sports an aluminium block. The IAT won’t offer the same protection to the aluminium block that the OAT is supposed to, which will lead to corrosion not only inside the coolant galleries in the engine block but also cause ancillaries such as the engine oil cooler to suffer. It is thus instrumental to pour the right coolant or pour distilled water as a stop-gap measure.

- If your car uses green coolant or any IAT based coolant, it is instrumental that you change coolant on or before time. As mentioned before, IAT becomes a bane as it ages and degrades, eventually assuming a corrosive state and encouraging rust in the coolant galleries and supporting ancillaries.

- For a layman, the easiest way to distinguish a conventional coolant from a long-life coolant is that conventional coolant concentrate would look green and opaque, while long life coolant would be clear and most importantly, oily to touch.

- Toyota’s coolant has an initial drain interval of 1.6L km and every 80K km thereafter.

- BMW uses an HOAT coolant that is both nitrite and phosphate free to prevent aluminium corrosion in its engines. It is blue in colour:

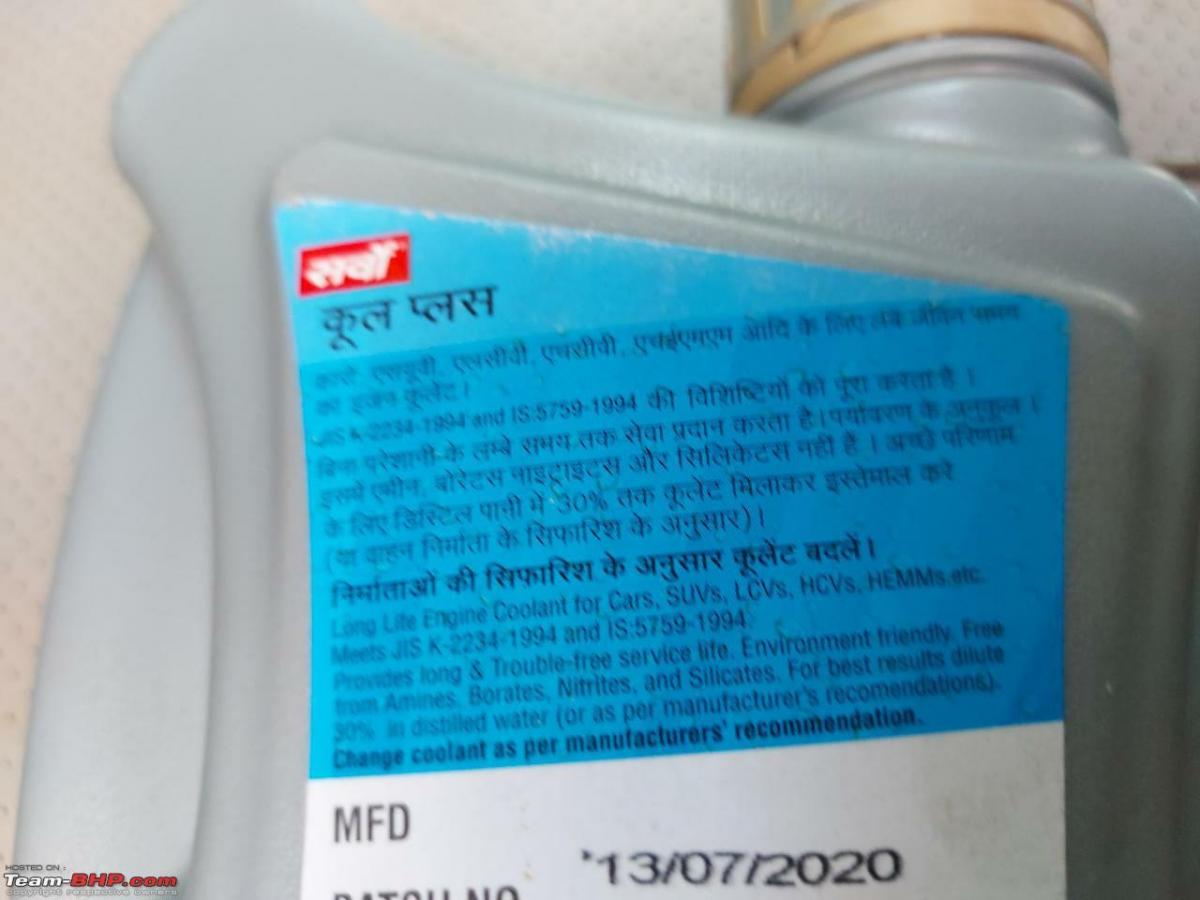

The last point but what is probably the most important one, the colour of the coolant (red, blue, orange, pink) does NOT define its chemical composition (HOAT, IAT or OAT). The same coolant colour across manufacturers may have variations in chemical composition. Always read what is written on the coolant bottle, consult manufacturer recommendations and then decide what is best for your engine (credits to BHPians Vigsom and Porsche_guy for both these images):

Here’s a short video by Scotty Kilmer that sums this entire post up.

Thanks to vishy76 again. Check out BHPian comments for more insights and information.

.png)