News

Turbocharging a stock Honda Brio: A fun and not-so-thirsty daily driver

My earlier builds - the Maruti Baleno had a TRD IHI turbo and my Maruti 800 had an MHI turbo. For the Brio, I am considering getting a Holset.

BHPian swiftboost recently shared this with other enthusiasts.

Hey guys, writing this to share my thoughts about my new turbo build. Yes, I am doing a turbo build for myself after quite a few years. Starting my build with an all-stock Honda Brio.

Has it ever crossed your mind that you could have used another 50-100HP in your daily drive... a car that will be more fun compared to some of the newer breed of NA hatches or you don’t like how some of the newer cars look or like me, can't afford the new hot hatches. Hmm, hopefully, my Honda BRIO Turbo will deliver similar or better levels of performance!

A lot of us have very similar ambitions for our cars. We often have a special bond between ourselves and the machine we drive. I think we create a new sense of ownership by taking on such a project.

I always enjoyed working on engines and ECUs and meeting other enthusiasts. My earlier builds have not changed my view on what I want from my everyday car. I want my daily drive to be more fun and rewarding while looking all stock and also expect it to be reasonably fuel efficient.

The 7+ year itch

I have always tried to treat myself to a simple and clean build. I often think of doing a build for myself (it remains in my thoughts for the most part) but it usually doesn’t happen that often though. Like most car guys, I love high-revving N/A motors. That said, I also love boosted dailys for its power & practicality. Well, the itch has finally got to the point that I decided to buy a used BRIO.

So, I bought this Honda BRIO sometime back with the sole intention of turbocharging it and making it a fun, not-so-fuel-thirsty daily drive. I figured that there still are a few out there who wish to do such builds or enjoy reading up about someone's build journey.

This thread will not be a start-to-finish complete build thread that covers the removal of every nut/bolt, the splicing of every wire, etc. This is more about the journey and why I choose to build cars for myself besides the fact that I can't afford the new breed of fast turbo cars!

The plan

The plan is no different to most of my earlier personal builds - to have a very stock-ish looking turbocharged car with all creature comforts. A clean turbo setup with an engine put together with OEM Honda parts. Obviously, most of the turbo-related parts would be aftermarket non-Honda parts.

If you’ve seen my old builds - Baleno G16 turbo build, they were pretty much stock engines with original factory pistons, rods, rings and bearings. I only ran a modest 9-10lb boost though. However, the Maruti 800 turbo ran about 14 PSI though.

I intend to push about 10-12 psi on this setup with a very conservative tune. I would need beefier internals to push any further. Going with a bigger displacement engine - L15 heart instead of the L12. Engine would be disassembled to ensure its running right clearances / tolerances for this build and the transmission will receive a new custom clutch to handle expected levels of torque. Please don't bash me for reasons like doing a turbo build on OEM Honda internals.

So let me begin with what I have in mind -Starting with a stock Honda L15 engine with OEM intake manifold and throttle body and a modified Air filter box, routing the Turbo plumbing to appear like stock. Before the engine goes in the block, drilled and tapped to accommodate the turbo oil return line. Turbos oil feed line will be taken from the oil pressure switch location using a custom oil splitter.

I had a few options for turbos – mainly from Garrett, MHI, IHI family. I usually opt for these brands for customer cars, my Baleno had a TRD IHI and my Maruti 800 had an MHI turbo. With my BRIO I am considering a Holset. In case I plan to push it further I can rebuild it with forged parts and throw a ton of boost at it.

Turbo selection

Having a fair amount of knowledge and experience with turbos, I started by comparing a few different compressor maps. These are some of the turbo brands and sizes that I thought would work well for this setup. The Garrett GT25 mid to large trim seemed like a good turbo, as did the MHI TD04 big trim or a TD05 small trim. The GT25 and TD04 turbos would spool quickly, but at a higher boost, these turbos' relatively small turbine side could cause high back pressure. The larger turbos like the Garrett GT30 or the smallest Borg (too large for this) turbo might be laggier compared to the other smaller ones.

The other turbo I was considering was Holset which I have used before. Holset turbos are mostly meant for large diesels and industrial applications. They have been used in some high HP / high boost gasoline applications. That said it's usually very laggy as-is for street turbo applications. For our requirement we would need a small frame Holset with a tight turbine side – hence a Holset custom Hybrid turbo. This hybrid Holset runs a relatively smaller A/R turbine side and should be able to support upto 250HP, and should not be very laggy and also have a fair bit of headroom for tomorrow. Besides the turbo size, the other important differences are the trims of the compressor wheel and turbine & the aspect ratio A/R. All things equal turbo with larger trims support more air flow.

These are some of the turbos used on builds in the past.

- TRD IHI turbo (Baleno 1.6 turbo)

- Garrett GT28 (Civic 1.8)

- Garrett GT14 (Abarth)

- Comp Turbo (Civic 1.8)

- Holset hybrid (Swift 1.3)

- MHI TD04 (City 1.5)

- MHI TD04 (Abarth)

- Aisin turbo (Maruti 800 carb)

- MHI TD025 (Maruti 800 FI)

- And now a Holset Hybrid

BRIO engine is out as we speak and health check-up for the donor engine.

Things to do before disassembling the engine:

Engine health check

- Oil Pressure:

Check oil pressure at idle. though optimal oil pressure readings may vary from engine to engine - manufacturers/ models. Usually, you should see around 20+psi at near idle, under acceleration the oil pressure should rise to around 60 psi. If your oil pressure is low, you have to root cause and remedy it, which may require the replacement of bearings and or the oil pump.

- Spark Plugs:

Spark plug condition can tell you a lot about an engine's health.

Oil fouled plugs mean - valve stem seals are leaking or there is blow-by and oil is being burned in the combustion chamber.

Wet plugs (fuel). Fuel injectors dumping excess fuel or injectors are too big and ECU is not able to reduce injector open duration enough.

Leaned out plugs. If you find a white-ish electrode tip, the cylinder may not be getting proper fuel and or spark plug being used is not of appropriate heat range.

A thumb rule is to use a colder plug when you go NA to turbo. On low-boost applications, stock plugs may work fine though.

- Compression Check:

If your compression numbers are more than 8-10 psi lower than the factory-recommended numbers, I would recommend fixing the issue before boosting it. Adding a little bit of oil can tell us if the piston rings are worn out. if you have a cylinder that's low on compression that jumps up quite a bit in compression due to the wet test, that can mean that the piston rings are worn.

A question often asked - Can NA Motor be Boosted reliably?

The answer is – YES, It can make a fair amount of more power and also a whole lot more torque. In the early 2000s, there were a few individuals that did turbo their na motors. Some of these builds were quite reliable and met the goals that it was built for. Some others weren’t as successful. The biggest reasons came down to GREED, fuel quality and tuning.

Let's start with greed. Boost is addictive and often when we get much more out of an NA motor, we get more greedy to extract even more out of it !! And that my friends is a one-way street to disaster... unless the engine is built ground up to deliver much more. Fuel quality was also limited to pump gas unlike high octane fuel options and octane boosters available today. Low octane fuel is more prone to detonation in a NA-forced induction motor owing to higher C:R in NA motors.

Last but not the least – a safe tune. There were limited tuning options back then. Most stock OEM ECUs couldn’t be reflashed and aftermarket programmable ECUs were let's say new to users in India. I have heard stories of many turbo builds marred with issues and some even deciding to go back to stock but I believe if you don’t cut corners and do it the right way without getting overly greedy for power, a reliable build is quite possible.

Intercooler selection

Selection is mainly based on the application and budget. Getting a HUGE intercooler capable of supporting 1000hp may be detrimental to performance on a 300hp application. The smaller the IC volume, the quicker it fills. A huge IC takes much longer to fill. Ideally, an intercooler should be sized to how many lbs/min the turbocharger can flow. End tanks also play a very important role in directing air flow. Air doesn’t like to go around corners. Air slows down in IC with a bigger cross-section and speeds up when the cross-section is small. Front-mounted IC is straight forward good option but often adds other challenges like additional intercooling plumbing (volume), and modifications required for routing.

My search for an intercooler took a fair amount of time. Started from taking exact measurements of available space for intercooler installation to checking various websites and going to auto store godowns looking for suitable IC. Finally found a Mahle brand intercooler of the right size that was nearly perfect for my application.

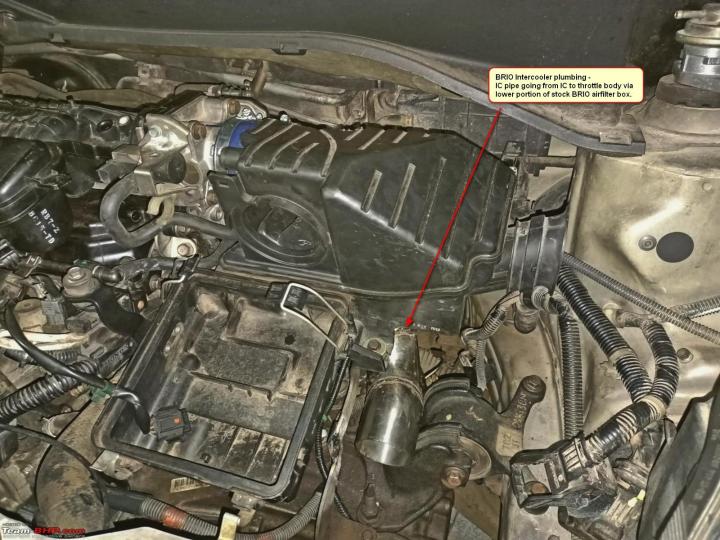

BRIO FMIC setup

Most of the plumbing was done with stainless steel pipes and OEM intercooler hoses from different makes. Based on my intercooler plumbing pipe diameter, my Compressor outlet diameter. Had to upsize my turbo plumbing for the IC pipe going out from the intercooler to the throttle body for it to match the size of TB. I got all the pipes, clamps and hoses locally. Some of them were custom machined though.

Turbine outlet is a V band type and since I did not find a suitable V band clamp, we machined one that could do the job well. Not the best-looking V band clamp though.

The length of the intercooler was just right, it starts and ends at the exact window size as my bumper lower grill. Had to make a small cut and weld onto the metal frame behind the bumper to get the intercooler fastened firmly and securely.

A whole lot of time and effort is going into how to do the plumbing to make it appear almost like a stock car. Most of the plumbing will not be quickly visible when you look into the engine bay. I think I may even lose a little power in the quest to make the plumbing least visible and retain stock like engine bay looks. For those of you thinking about building your own FMIC setup, by all means, go for it.

Here are some pics of the IC pipes installed on the car. Most of these pics are taken late in the evening with my old phone.

Continue reading about swiftboost's build for BHPian comments, insights and more information.