News

Global NCAP crash tests explained in detail

When Global NCAP tests a model, they pick a variant that is specified with the basic safety equipment available for the model at the time of the test.

BHPian ron178 recently shared this with other enthusiasts.

t’s been seven years since Global NCAP started its Safer Cars for India project and the market has come a long way since then. Not only do we now have minimum regulatory crash tests for homologation, for front (offset and full-width) and side impact and pedestrian protection, but we have also seen some excellent safety performances, including a number of five star cars for adult occupant protection, and we’re now waiting for the first five star rating for child occupant protection too.

I’m going to describe the entire process to the best of my knowledge and hopefully clear some lingering questions.

What is Global NCAP? (besides the standard PR talk on their website)

Global NCAP is a project of the Towards Zero Foundation (a UK-registered charity).

This might sound funny, but initially, it was not an NCAP at all. It was primarily founded to serve as a platform for cooperation among all NCAPs (and the IIHS) and to provide support for new NCAPs in emerging markets, like ASEAN NCAP and Latin NCAP.

Since 2014, Global NCAP’s Safer Cars for India project has functioned as an NCAP by itself. They have a small team and their PR is handled by a UK company called Advocacy Impact. While I trust that the data provided by the test lab is accurate, Global NCAP's PR team does make quite a few mistakes in their publications and press releases, which creates some confusion for consumers and reviewers. The most recent effect is that the integrity of the tests has come under question, which is definitely something unacceptable for the very organisation that gives us an important part of information about the safety of the cars we buy.

Next year, Global NCAP will be relaunched as a partnership instead of a project.

How the cars are selected, purchased and tested:

There is some ambiguity in this regard because Global NCAP has not published its Car Sponsorship, Selection, Testing and Retesting (CSSTR) Protocol for consumers to view, so I’m going to pen down my observations based on usual NCAP CSSTR protocols and Global NCAP's statements.

Non-voluntary testing:

- An annual selection of a few cars is made from the market, from cars that are very popular or cars that are not deemed likely to be sponsored by manufacturers or cars that are expected to perform poorly (based on a lack of equipment or an international test on the same model, for example). Tests for these models are funded by Global NCAP’s sponsors, namely the FIA Foundation, Bloomberg Philantropies, the ICRT and the UN Road Safety Fund.

- A tentative date and time for announcing results is pre-decided.

- A secret shopper purchases the cars from dealers like a regular customer would.

- The cars are sealed and shipped to ADAC Technik Zentrum’s crash test facility in Landsberg am Lech, Germany.

- The manufacturers are informed that their cars have been selected for testing and their representatives are invited to witness the test and to provide any necessary information (recommended child restraints, whether or not deployment of curtain airbags is expected so that alternative high-speed camera mounting positions may be used, and many more).

- The seatbelt reminders (if equipped) are assessed and the frontal crash test is conducted according to a test protocol (which defines the configuration to be used for the test and is detailed below) and dummy data is analysed, the car and high-speed recordings are inspected and an assessment is made based on a protocol.

- Manufacturers are informed of the date of the one-to-one meeting so that they may present any additional data that may be required, like knee mapping sled tests, or an offer so sponsor the UNECE Reg. 95 side impact test in case the car qualifies for five adult stars.

- The final score and star rating is determined.

- The result is published, and results of any extra sponsored tests that were not used in the result are published separately.

Sponsored testing:

- The manufacturer makes a sponsorship offer for a model, including any other tests (than the frontal offset test) that they deem necessary for determining the final score, like side impact or ESC.

- A tentative date and time for announcing results is pre-decided.

- If the model is already on sale: A secret shopper purchases the cars from dealers like a regular customer would.

- If the model has started production but is not on sale, and the manufacturer wishes to use the result in the market launch: Global NCAP representatives select a car with basic safety equipment at random from the plant's distribution area.

- The manufacturer's representatives are invited to witness the test(s) and to provide any necessary information (recommended child restraints, whether or not deployment of curtain airbags is expected so that alternative high-speed camera mounting positions may be used, and many more).

- Additional data that may be required is provided at the one-to-one meeting.

- The final score and star rating is determined.

- The result is published, and results of any extra sponsored tests that were not used in the result are published separately (for example, the Mahindra Thar, whose side impact test could not be used in the result because the frontal offset test score didn't meet minimum requirements for five stars).

- The manufacturer is invoiced for all costs related to the vehicle purchase, transportation, test lab fees et cetera.

Which trim level is tested?

When Global NCAP tests a model, they pick a variant that is specified with the basic safety equipment available for the model at the time of the test. In addition, the manufacturer may sponsor a test on a model equipped with optional safety equipment to demonstrate its benefits, like the Volkswagen Polo, Renault Duster and Kwid, and the Honda Mobilio. 'Basic safety equipment' does not necessarily imply 'base variant' (another probable goof by their PR team).

Disclaimer: Since Global NCAP protocols are usually very similar to older Latin NCAP protocols, I will be using some old Latin NCAP references in cases where a Global NCAP protocol is unavailable.

There have been numerous cases where a high variant (but with basic safety equipment) has been tested. Autocar keeps claiming that it has something to do with alloy wheels, but there is no evidence for this except a vague statement by Tata Motors' CTO. I think manufacturers sponsor a higher variant in order to use it in publication (since a variant with steel wheels and black handles and mirrors would not look good in publication images), however, I have no evidence for my claim either. However, Latin NCAP's 2016 CSSTR protocol clearly states that wheels are not considered safety equipment:

It does not include:

- Engine/transmission volume.

- Road wheel/tyre size.

- Sun roof.

I am not sure if this is any different for Global NCAP.

The Frontal Offset Test Protocol:

At present, the Global NCAP assessment is primarily based on a frontal crash test into an offset deformable barrier at 64±1km/h, whose test protocol is similar to that used by most other NCAPs.

The test protocol is standardised and is intended to enable a fair assessment with uniform test configuration for cars regardless of size or class, to produce repeatable results. There is very little room for ambiguity.

The test configuration is identical to 2013 Latin NCAP protocol, which is what I have used for reference.

Before we start, let's get familiar with the types of dummies used:

- Hybrid III: a family of dummies widely used in crash testing. They are used to represent adults and can be used for both front and side crash tests. They are not the most advanced but are versatile and have been used extensively all over the world.

- Hybrid III 50th percentile: The type of dummy placed in the front seats for Global NCAP's crash tests. They represent a 50th percentile adult male and weight 77.7kg without the instrumentation.

- Hybrid III 5th percentile (often called "Ms. Hybrid III"): Not used by Global NCAP. This is a smaller dummy that represents a short female adult. Similarly, the recent, more advanced THOR and worldSID dummies (for frontal and side impact respectively) are not used by Global NCAP yet.

- P-series dummies: An archaic child dummy that was used in Global NCAP's tests till 2017. These lack modern instrumentation and were developed at a time when there was an acute lack of data for development for child dummies.

- Q-series dummies: Relatively modern child dummies that have been used by Global NCAP since the 2017 revision. They are still far from perfect, due to a lack of anthropometry of children.

- Child dummies are specified using the series followed by the age the dummy is intended to represent, for example, Q3 means a Q-series dummy that represents a 3-year old.

I will be explaining a few salient points directly from the test protocol. Some of them have mathematical systems that I have not yet been able to comprehend, so I would request anyone interested to please read the protocol directly. This post is mainly composed of a simplified interpretation of some relevant points from the test protocol.

The test protocol can be found here.

Unladen kerb mass:

- The test lab first finds the unladen kerb mass of the car (different from test mass) as defined in the test protocol.

- The fuel is emptied out.

- Using the manufacturer's specified fuel tank capacity, the mass of ballast to be filled is calculated using a density of 0.745g/cc for petrol and 0.840g/cc for diesel.

- Engine oil and other fluids are topped up.

- The spare wheel and all tools supplied with the car are kept in the car, and nothing extra.

- Tyre pressures are maintained according to manufacturer instructions for half-load.

- The unladen kerb mass is calculated using front and rear axle masses.

Reference mass:

- The following method is used to calculate reference mass:

- 90% of the ballast in the fuel tank (calculated in the previous section) is left in the vehicle.

- The front and rear seats are placed in the middle fore-aft and height (if available) positions.

- A mass of 88kg (the mass of a Hybrid III 50th percentile dummy) with the instrumentation and cabling) is placed in each of the front seats.

- Masses of 15kg in place of the Q3 dummy and 11kg for the Q1.5 dummy are placed in the respective rear seats in the child restraints specified by the manufacturer.

- The reference mass is calculated using front and rear axle masses.

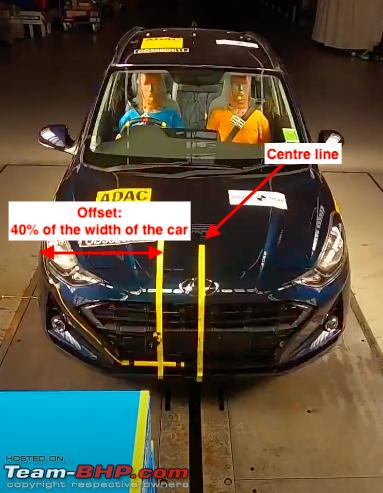

Offset:

- The vehicle width at its widest point is calculated, excluding ORVMs, mud flaps, etc.

- The centre line is marked with tape and 10% of the distance between this and the widest point is calculated. This distance left of the centre line (for RHD cars) is marked with tape, and this is the position where the edge of the offset deformable barrier meets, making for 40% offset.

Centre line and offset marking on a test car - the Hyundai Grand i10 Nios.

Vehicle Preparation:

- The battery must be connected to the electrical circuit. There are detailed instructions for additional batteries.

- In case fluids must be drained they must be replaced by suitable noncombustible ballasts of similar density.

- Thoughtfully, it is not allowed to vent HVAC fluids to the atmosphere.

- An abort system is optional.

- The boot carpeting is removed, and the spare wheel is removed if it is deemed that it will not affect crash performance.

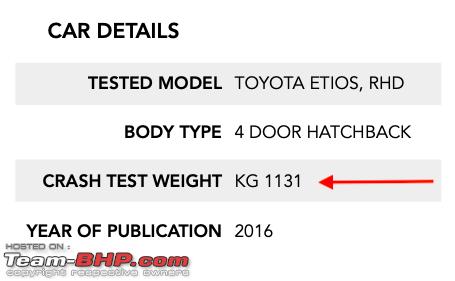

Test mass:

- The on-board data recording equipment is placed in the boot and the mass of the car is measured as in the reference loads section. If this mass exceeds reference mass by more than 5% or 20kg (whichever is less), non-structural parts are removed to adjust it.

- This is the mass of the car with dummy dummy* masses, child restraints, ballast and recording equipment installed.

- The test mass is calculated using front and rear axle masses using the method specified under 'reference loads', and is specified in the test report published by Global NCAP.

Test mass specified in the test report for a Toyota Etios.

This is a common question on the internet and it has been said time and again - the test mass is not the kerb mass.

*not a typo

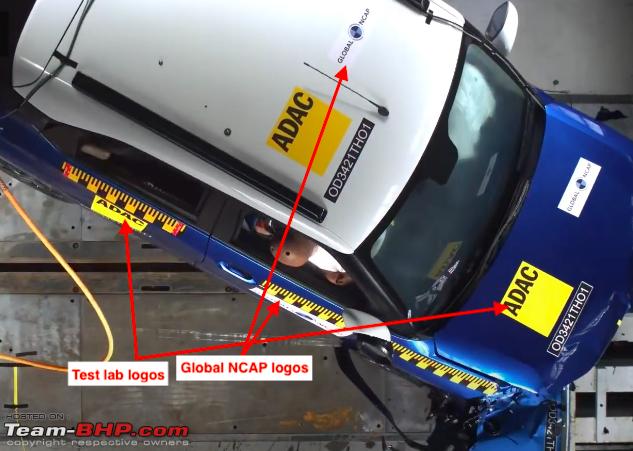

Markings and labels:

Global NCAP labels in English are attached on the top half of the driver and passenger doors and on the front half of the roof.

Test lab logos may be added to the lower half of the rear doors and to the hood at the base of the windscreen.

NCAP and test lab markings on a Tata Punch:

- The rear doors of the vehicle are marked on the interior and exterior for lengths of at least 400-600mm in 50mm increments so that forward excursion of the child dummies can be measured, and the on the exterior of the front door similar markings are attached to assess movement of the front dummies on the high-speed film (for example, for unstable contact on a steering wheel or on an airbag).

Markings showing excursion of the Q3 dummy in a Honda Amaze.

3D measurement system:

- This is rather complex so I would advise anyone interested to view the attached Latin NCAP test protocol.

- There is a measurement system that is based on fixed reference points on parts of the car that are not expected to deform and there are coordinate axes defined. This is mainly used to determine A-pillar displacement, pedal movement, steering column movement and dummy excursion.

Dummy preparation:

- The adult dummies are certified after every three tests according to the provisions of UNECE Reg. 94.

- Child P-series dummies were certified after every six tests but I am not sure about Q-series dummies.

- Clothing and footwear to be fitted to dummies is specified in the protocol.

- The dummies must be soaked in a temperature of 19-22ºC for at least 5 hours before the test and upto a maximum of 10 minutes before the test.Stiffness of dummy joints is set by a qualitative method.

- Masking tape of specified size is applied to various regions of the dummies and paint of specified colour is applied to it just before the test to make sure it is still wet on impact.

Wet yellow paint being applied to the forehead of the Q3 in a Mahindra Marazzo a few minutes before the test.

Dummy and vehicle instrumentation:

- Please see test protocol for details.

- Sensors are fitted in the dummies which record different physical parameters for different body regions.

- Accelerometers are fitted to the B-pillar of the vehicle.

- Seatbelt loadcells are fitted to the shoulder area.

Seatbelt loadcells visible above the shoulder area in a Renault Kwid after pretensioner deployment, with pretensioner deployment indicated by separation of the pieces of paper at the chest area.

A seatbelt loadcell.

Camera location:

- Ten camera positions are mandatory, out of which some are displayed in the test video.

- Look at the bottom left of the test video to find out which camera you are viewing.

- The high-speed cameras must meet Euro NCAP requirements.

Bottom left: Camera view specified in a published test video for the Tata Punch, here: 'Driver head tight'.

Passenger compartment adjustments:

- Seat fore-aft adjustments, head restraints, adjustable steering columns, adjustable pedals and other available adjustments in the passenger compartment must be set according to protocol. Some of these are as recommended by the manufacturer, and if the manufacturer fails to recommend positions there are default cases considered.

- A 'Gabarit' is used to determine compatibility of Universal CRSs, and more information about this can also be found in the assessment protocol for Child Occupant Protection.

Dummy positioning in the seats:

- If the vehicle has never been sat in then a person of mass 75±10kg must sit in the driver and passenger seat twice each for 1 minute to flex the cushions.

- The dummy must not be placed in the seat for more than 2 hours to prevent unnecessary compression of the seat.

- An H-point machine is used to determine the H-point of the seat which is used to define the position where the dummy will sit. Refer protocol for more details.

- If adjustable, the upper seatbelt anchorage should be positioned in the position the manufacturer specifies for a 50th percentile male (if not, a default case is used). There are other similar adjustments for the seat belt.

- Child restraints are based on manufacturer recommendation and there are further instructions. Please see protocol.

The test:

- The offset deformable barrier test uses the standard deformable barrier, which will be covered later.

- The barrier is placed at 200±5mm above the ground.

- The overlap is 40%±20mm.

- The test speed is 64±1km/h and must be stabilised for a given distance before impact.

The barrier:

The deformable barrier is made of an aluminium honeycomb and is composed of a main honeycomb block (that represents the longitudinal crash members (crumple zone) of the opposing car and a protruding bumper element. The materials, adhesives, crush strengths and honeycomb shapes and spacing are specified. The barrier must be certified according to an NHTSA protocol before use. Due to the large number of crash tests that occur throughout the year, these barriers are usually purchased in bulk from manufacturers (like Argosy International).

Please be reminded that the above is only a concise explanation of the actual test protocol. For complete information, read the test protocol linked above.

Continue reading on the Global NCAP crash tests for BHPian comments, insights and more information.