News

How I got my expensive Alpinestar riding boots repaired in Pune

While the leather and zippers and velcro were pristine, the heelcups had cracked and were literally falling to pieces. Add to that, the heel of the sole on one of the boots had started coming out, parting way with the upper

BHPian ebonho recently shared this with other enthusiasts.

When I was getting all my riding gear out of storage, I got a nasty shock to find that my favourite Alpinestars, which I only wear on fast group rides, preferring my softer less armoured WP GoreTex RSTs for longer tours, had really started disintegrating in storage for some strange reason.

They are the way more expensive pair. Genuine full grain leather. Sliders. Heavy shin and ankle protection. Hard plastic heel cups. Rubber shift pads. But while the leather and zippers and velcro were pristine, the heelcups had cracked and were literally falling to pieces. Add to that, the heel of the sole on one of the boots had started coming out, parting way with the upper.

The RSTs for their part are not leather but synthetic uppers, and the uppers had started cracking during and after the Sikkim ride. The most concerning is the large transverse crack on the top of the foot on both boots, right behind the reinforced double leather layer shift pads. The soles were holding good, as were the zippers and velcro.

From prior experience with local cobblers on the road, as well as those sitting in small shops in Shivaji Market, I knew that their grade of glue solution was not going to be strong enough to hold. I went to DSG next door to ask them if they had anyone who could repair my boots, and whether they had spares of the original heel cups. They said they too would be taking the boots to cobblers outside. So I thought why not I do it myself, instead of going through them. Especially since they did not have the required hardware in the firm of new heelcups, and toe sliders (which had broken and come off on one boot).

My old Bullet buddy sturdy friend Baljeet and Irani kickboxing legend and coach Ismaile told me they both take their boots to the mochkhana on MG Road, adjoining Royal Bakery. Here you will find in a single shop 15-20 cobblers, mostly from north Bihar, plying their trade. Experts at making boots for the police as well as horse riding boots.

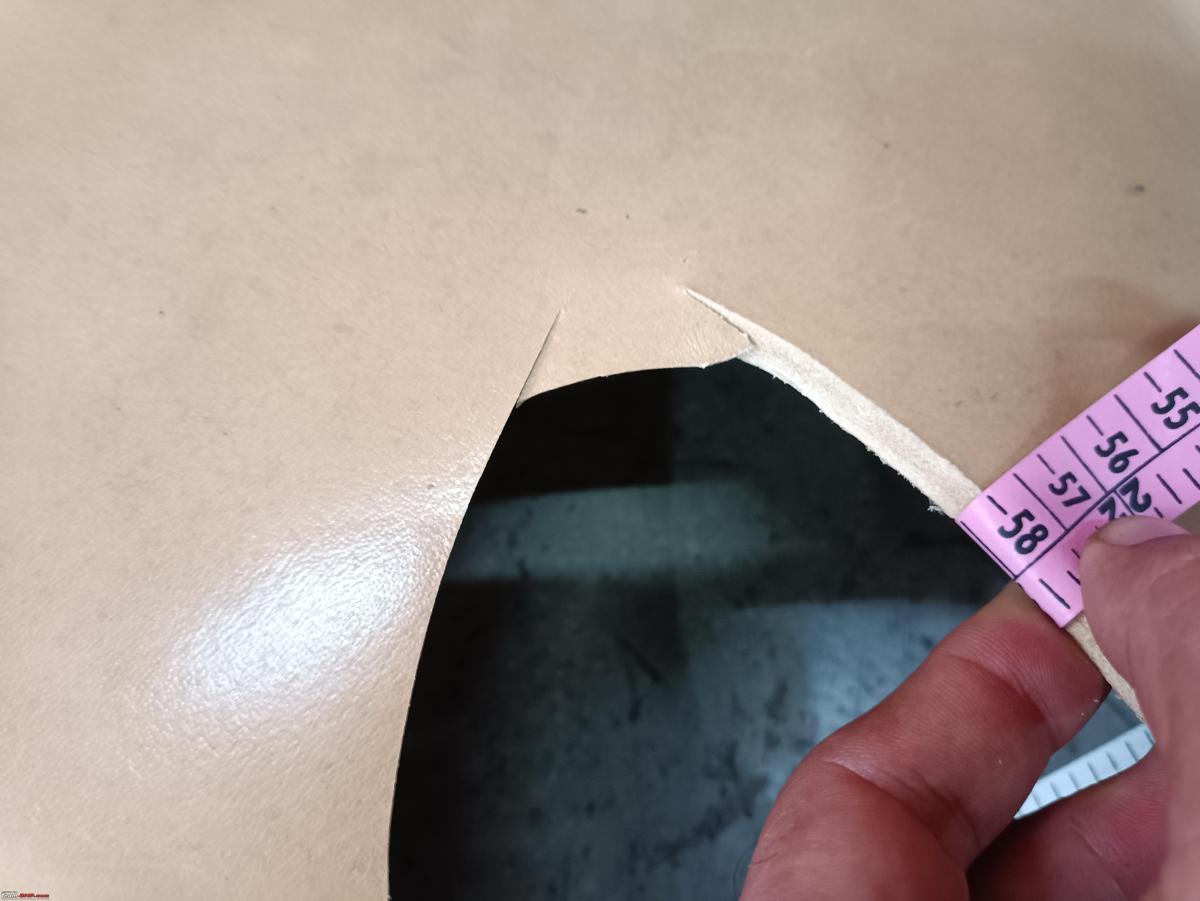

I took my boots there and met a very enthusiastic young guy who said he works on motorcycle boots daily, so many riders coming there. When he saw my battered boots he did not bat an eyelid and told me 9 out of 10 boots that come to him have the exact same damage and failures. He initially suggested a rubber sheet patch for the heelcups but I told him I wanted something a lot more stiff. So we settled on a 5 mm thick rawhide sheet that was used to craft genuine leather soles for their handmade boots.

However, this leather was so stiff that it would take two days to wet and bend and mould into the shape of the heel cups, on a past, before they could be glued and stitched into place along with the inners and the soles. The shift pads on both boots also have the same leather. And over the rawhide, he pasted and stitched a layer of normal soft black leather for the show. For the RSTs, two similarly shaped patches were glued on the tops of the uppers, behind the shift pads, but not stitched through, so as not to compromise the waterproofing.

Here is the young man, and his very neat work -

When I had initially seen the condition of the falling to pieces Alpinestars I had honestly written them off completely. So now, with his, whatever use and life I get out of them will be a bonus. Our man is confident of his materials and work and says teen-chaar saal pretty nonchalantly. We shall see!

Cheers, Doc

Check out BHPian comments for more insights and information.

- Tags:

- Indian

- Member Content

- Riding Boots