News

Maruti Suzuki resumes operations at Gurgaon, Manesar plants

On February 20, Maruti Suzuki had to temporarily suspend operations at its facilities in Gurgaon and Manesar as the supply of certain components was disrupted due to the agitation in Haryana. Now, the company has issued a statement stating that it has resumed production of vehicles at its two facilities starting Tuesday, February 23 (second half). The supply of components has started gradually.

At present, the combined output from the Manesar and Gurgaon plants is about 5,000 vehicles per day.

News

Honda's 4th two-wheeler plant in India inaugurated

Honda Motorcycle & Scooter India has inaugurated its fourth manufacturing plant in India and the plant will exclusively produce automatic scooters. The plant is located at Vithalapur (Mandal taluk, Ahmedabad district, Gujarat) in India. The company has made an investment of INR 1,100 crore for the plant which has been setup in 13 months. Honda’s 22 suppliers have invested an additional INR 1,100 crore as they set up ancillary plants in Gujarat.

Spread over 250 acres, operations of Honda’s fourth plant have been scheduled in two phases, the first of which starts today. The first production line has an annual production capacity of 6 lakh units. This production line will be followed by a 2nd line in mid-2016 that will produce an additional 6 lakh units. In all, Honda will manufacture 1.2 million automatic scooters annually from its fourth plant.

Honda’s total two-wheeler production capacity in India is expected to increase by 26% to 5.8 million units by the end of 2016. This number includes 1.6 million units from its plant in Haryana, 1.2 million units from its second plant in Rajasthan, 1.8 million units from its third plant in Karnataka and 1.2 million units from the fourth plant in Gujarat.

Honda claims that the plant will generate 3,000 jobs directly and 6,000 additional jobs through suppliers who have setup plants of their own in Gujarat. The plant features a fully-automated press shop, vacuum cooling technology and nitrogen pressurization in die-casting, use of digital eye technology in various processes and traceability of in-house parts with QR codes in the machine shop.

Over 1/3rd of the plant's total area is a dedicated green zone and the facility has a zero liquid discharge plan with a rain-water harvesting system as well.

- Tags:

- Indian

- Manufacturing Plant

- Scooter

News

Isuzu no longer assembling cars at HM's Chennai factory

Isuzu has started the process of moving production from the Hindustan Motors plant in Tiruvallur, Chennai to its own facility at Sri City, AP. The company has stopped rolling out vehicles from the Chennai facility from December 2015.

Isuzu had been using the Hindustan Motors plant to assemble the MU-7 SUV and D-Max pickup truck. While the new plant isn't expected to start producing vehicles before April 2016, the company believes it has enough vehicles in stock to meet the demand till then.

Isuzu has invested Rs. 3,000 crore in the new plant. Initially, the facility will have an annual production capacity of 50,000 units. This number can be expanded to 1.2 lakh units.

It has also formed 'Isuzu Engineering Business Centre India Private Limited', a new company that will be responsible for R&D and sourcing related activities. This company is expected to help Isuzu achieve 70% localisation at the start of production and 100% localisation in the future.

Source: ET Auto

News

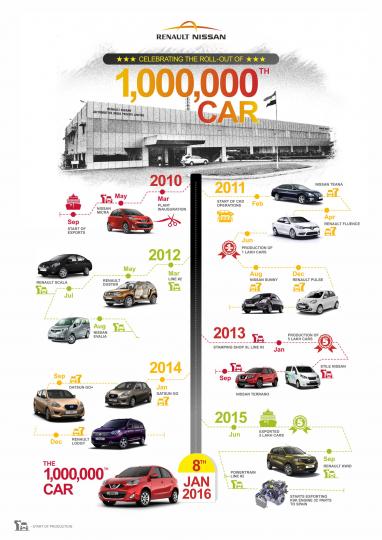

Renault-Nissan's Chennai plant rolls out 10 lakh vehicles

The Renault-Nissan Alliance plant in Oragadum, near Chennai, has achieved the milestone of rolling out ten lakh vehicles. Car no. ten lakh - a Nissan Micra, was rolled out at 1215 hours on January 8, 2016.

The plant was built with an initial investment of Rs. 45 billion and began operations in 2010. The company has invested a further Rs. 16 billion since then to increase its capabilities. The plant's annual production capacity has been increased to 2,00,000 in 2015, from 75,000 units (in 2010).

The alliance also has a research and development (R&D) facility in Chennai. The plant and the R&D facility combined account for 12,000 direct jobs in Tamil Nadu and 40,000 more jobs in the Indian supplier chain.

The plant has rolled out 32 Renault, Nissan and Datsun models and derivatives and caters to the Indian as well as international markets. It is India's second largest car exporter with more than 6,00,000 units shipped to 106 countries.

News

Royal Enfield plans third plant to double production capacity

Last year, we had reported that Royal Enfield had purchased land to set up a new manufacturing plant (click here to read report). This plant is expected to come up in Vallam Vadagal near Oragadam, Tamil Nadu.

The new factory will be built on 50 acres of land have been purchased by Royal Enfield for Rs. 57 crore. The construction of the plant will start next year. The company aims to double its production capacity to 9,00,000 units per annum from the current 4.5 lakh units by 2018.

At present, Royal Enfield has two manufacturing facilities - one in Thiruvottiyur and one in Oragadam. The demand for the company's products rising and there is a waiting period for them. In the period January-October 2015, Royal Enfield's sales stood at 364,178 units. In the same period last year, the company sold 2.40,993 units.

The company has already increased the capacity of its Oragadum plant to try and reduce the waiting period. The third plant will help immensely in catering to domestic and international markets.

Royal Enfield is working on two new platforms. While the product on the first platform will be launched in 2016, a product on the second one will be launched in 2017.

Source: ET Auto

News

Ford's Chennai plant rolls out 1 millionth vehicle and engine

Ford's Chennai plant has produced its one millionth vehicle and engine. Vehicle number 1 million to be rolled of the assembly line is a Ford EcoSport.

The US$ 1 billion manufacturing facility at Chennai started commercial production in 1999. It is spread over an area of 350 acres and houses an engine assembly plant that started commercial operations in 2008. The facility has an installed capacity to assemble up to 2,00,000 vehicles and 3,40,000 engines a year.

The engine plant features Ford's single-flexible production line, configured to build both petrol and diesel engines simultaneously. Models built here include the EcoSport, Fiesta and Endeavour.

Apart from catering to the domestic market, cars manufactured at the Chennai facility are exported to more than 40 markets around the world, including some ASEAN countries, Europe, Middle-East and Africa.

Ford claims that it has implemented environment-friendly practices at the Chennai plant and it is one of Ford’s five zero-landfill facilities in the Asia Pacific region. The entire hazardous waste generated at the plant is either recycled or co-processed into allied cement industries.

Additionally, the company claims to have reduced its energy consumption at Chennai by 16% while water consumption by 30% in producing each car since 2009 through various process improvements. The plant also treats and reuses 100% of its water within the facility, making this a zero liquid discharge factory.

News

Magneti Marelli inaugurates new AMT plant at Manesar

Magneti Marelli has inaugurated a new facility in Manesar. This is the Italian company’s eleventh plant in India. It is built on an area of 7,500 square metres and the company has invested Rs. 150 crore in it.

Magneti Marelli will use the facility to manufacture automated manual transmissions (AMT). The popularity of the technology has been on the rise in India since it was introduced in the country in 2014. The company claims that more than 50,000 AMT units have been sold in 2014. At present, Magneti Marelli’s AMT technology is used in Maruti Suzuki and Tata cars.

The new plant is capable of churning out 2,80,000 AMT units every year and is expected to employ 115 people when fully operational. At present, it is manufacturing 1,20,000 AMT units annually. The plant will supply AMT kits to the domestic market and could also be used to cater to export markets.

Magneti Marelli will also continue importing AMT kits from Italy for use in the Indian market. At present, 4-5% of the Indian market uses automatic transmissions, out of which, more than 50% are AMTs. According to the company, the market for automatic transmissions is expected to grow to 30% by 2020.

Source: ET Auto

News

Mahindra's Haridwar plant rolls out 7 lakh vehicles

Mahindra has rolled out the 7,00,000th vehicle from its plant in Haridwar, Uttarakhand. The plant has achieved this milestone in less than 10 years since it became operational.

Inaugurated in December 2005, the Haridwar plant currently manufacturers the Bolero, Scorpio S2, Gio (passenger & load), Alfa (passenger & load) and Champion range. For the past two years, the plant has had one of the highest production capacities among other automotive plants of Mahindra. It is the company's sole automotive plant in North India.

The plant's earlier production milestone of 6 lakh vehicles was achieved in November 2014.

Mahindra's other manufacturing facilities are located in Chakan, Nasik, Zaheerabad, Kandivali and Igatpuri. All facilities are equipped with a press shop, body shop, CED Line, paint shop and assembly. The company's engine plant is located at Igatpuri.

News

Audi to increase investment in India, ramp up manufacturing

Audi is gearing up to announce a fresh investment in India. This investment will be used to enhance its manufacturing set-up in the country. The company has not disclosed the amount it plans to invest.

In 2013, Audi overtook BMW to become the most popular luxury car brand in India. It also became the first luxury carmaker to sell more than 10,000 units (10,002) in a calendar year. In 2014, with sales of 10,851 units, the company retained the first position. However, arch rival Mercedes-Benz, with sales of 10,201 units, had closed the gap significantly. In the first half of 2015, Mercedes-Benz had sold 6,659 units, reflecting a growth of 41%, and taken the lead. Audi still believes it can finish ahead of Mercedes-Benz at the end of the year. The company expects to retain the 34% market share that it achieved in 2014.

The luxury car market accounts for just 1% of the overall passenger car market. Last year, the total number of luxury cars sold stood at around 33,000 units. With the increase in disposable income and easier finance schemes, this share is expected to go up.

Audi cars are assembled at the Skoda factory in Aurangabad. The company can produce 14,000 units on an annual basis, working on a single shift. Audi has invested around 30 million euros (Rs. 220 crore) till now.

Source: Times of India

News

Force Motors inaugurates its BMW engine manufacturing plant

Force Motors inaugurated its newest facility at Mahindra World City, Chennai. Set up at an investment of Rs. 200 crores, the company will manufacture and test diesel engines for BMW.

As a part of a contract manufacturing deal between BMW and Force Motors, the latter will locally manufacture 4 and 6-cylinder diesel engines for various BMW cars sold in India. Transmissions are produced and mated to the engines at this facility itself.

The plant was formally inaugurated by Anant Geete, Union Minister for Heavy Industries. Force Motors has already supplied 3,000 units since January 2015. It has a capacity to manufacture 20,000 engines annually, which can be further increased to 50,000 units.

Earlier this year, BMW reported to have increased the levels of localization in India to 50%. As a result, the company recently announce revised prices of its cars (related article).

BMW is the second German car maker who utilizes Force Motors' service for engine assembly. The company has been assembling engines for Mercedes-Benz at its Pune plant.

Pages