Team-BHP

(

https://www.team-bhp.com/forum/)

This thread is related to flooring, tyres, traction and all. Guess no one has asked such a query yet.

Recently paved our car porch and courtyard with vitrified outdoor tiles. (Johnson Endura Industrial tiles) It is very strong & clean. The surface is slightly glazed but seemed to have good grip. 80% of the courtyard is flat & only 20% is inclined. The problem started when it rained for the first time. Could walk easily with good footwears. Shocked to see that it has NO grip for wheels. Attempted to drive M 800 , it came up to 50% of the inclined portion, lost traction, stopped (obviously applied brakes) wheels locked & started to slide backwards quickly. Somehow managed not to hit the walls. Did many repeated attempts and the result was same.

Even if you are coming downwards, if you apply brake midway, the wheels will get locked and the car will slide downwards easily. It's totally impossible to ride a two wheeler.

Heavier cars are getting more grip as the downforce is higher. Some cars can climb it in reverse if the surface is only slightly wet. Gypsy Manages to climb in 4L with 235 tyres. But it's tricky & risky.

Anyway, the tiles are not water absorbant and will be completely dried in 15-20 min. Also it has good grip with rubber when dry. No traction issues in flat surface.

Some pics:

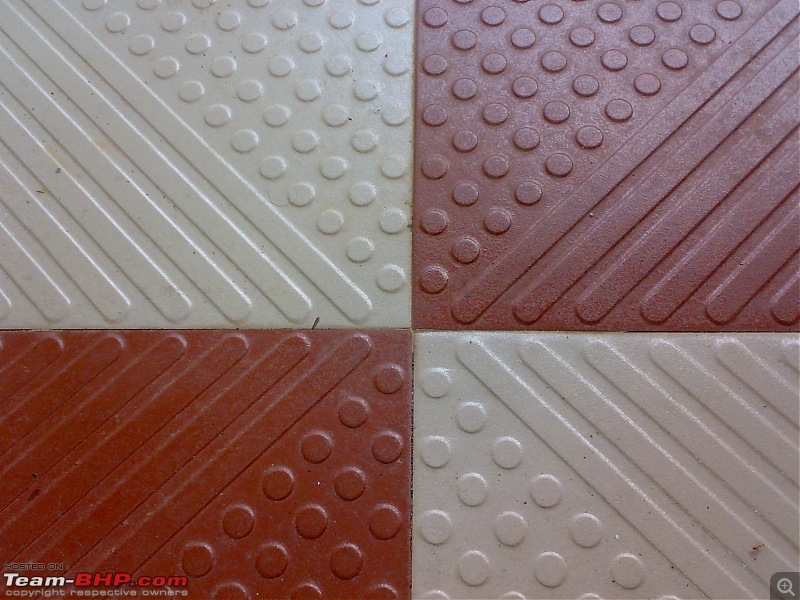

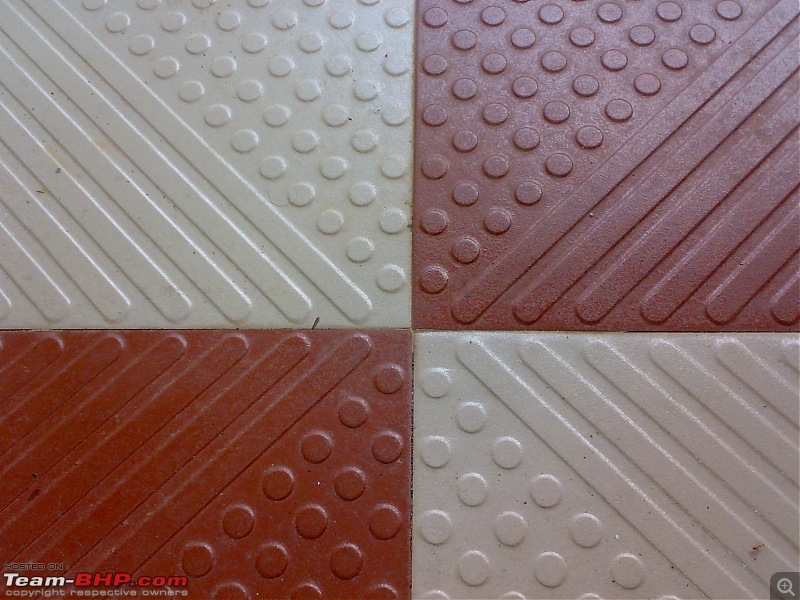

This is how the surface looks like.

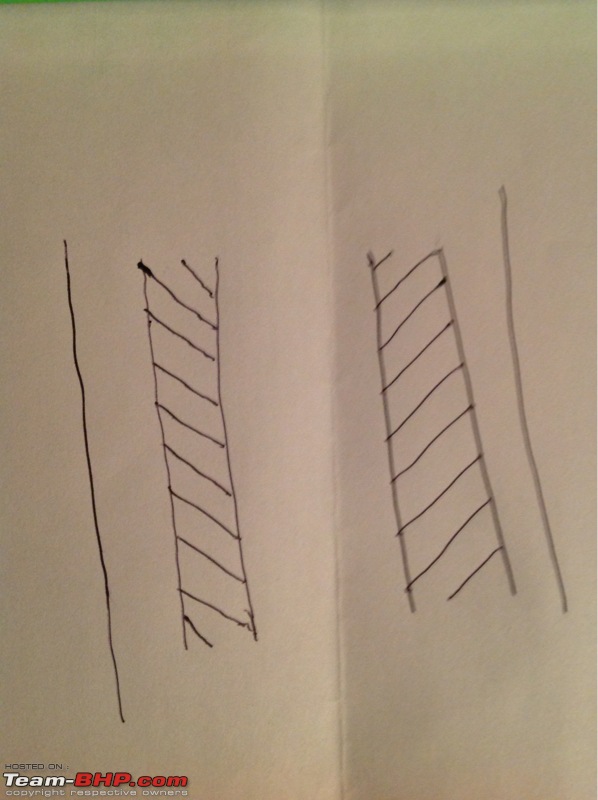

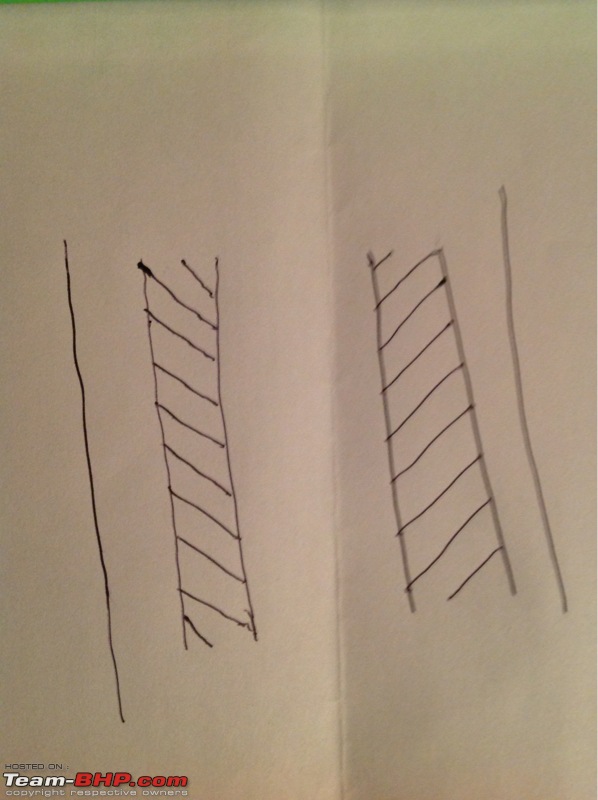

To get an idea of the slope.

It's not a good idea to replace it completely. Searched the internet and found some remedies.

Grip strip/ sticker type - as seen in some malls. Not sure whether it will work when whet.

http://www.allstairtreads.com/gritstrips.html http://www.kofflersales.com/3m-safet...pe.asp?cid=858

Grip plates- it can be screwed to the tile surface.

http://www.antisliptapeshop.com/Prod...Slip-Plates/48 http://www.algrip.com/products.htm

Any idea where can I get similar stuff in India? Any other tricks? Any low cost alternatives? Any jugaads? Any driving techniques? Please help. please:

PS: Use these tiles outdoors only if the surface is flat and enclosed. You can use interlocked cement blocks otherwise.

You can paste strips of tiles/granite of about 2 inch wide horizontally across the slope at a distance of 8-10 cms to gain traction. It could be fixed with a strong industrial grade adhesive like Araldite. Though it would be difficult to clean, as dust and debris would get accumulated across the strips.

Else you can place 2 chequred metal strips of about 1ft wide on the vertical path where the car's tyre would come in contact. You could easily screw the plate by using flat head stainless stell screws at several places.

I guess stickers are suitable only for indoor use. Heat/Sunshine and rain would destroy the grip stickers very soon.

I think the design itself is wrong . Tiles are good for FLAT surface , the idea of tiling on inclined surface was wrong as I think .Also the incline looks steep .

Although it looks good for whole portion , you should have cemented or stoned the inclines portion and tiled only flat area .

I remember my previous office parking bay had similar kind of tiles. Not the complete parking area, only some 2 rows or so where you enter/ exit the bay. When it rained, it was nightmare for the people who parked here! Especially the two wheelers guys were seen skidding every now and then as if they were riding on marbles! I myself had skidded twice and for all the coming days I rode not more than 8-10 kmph!

Thats a very very weird design. Tiling on slopes should never be done. Its not only inconvenient, its potentially dangerous as well.

Never seen anything like this before.

Advise you to do away with it altogether.

More than loss of grip for tyres, it would be more dangerous if someone were to fall when climbing the gradient during the rains. As suggested by another member, the easiest solution would be installing rumble strips. I cant think of a more easier solution, or one that involves minimal expenditure.

Quote:

Originally Posted by BuildUpGypsy

(Post 3095191)

Any low cost alternatives? Any jugaads? Any driving techniques? Please help. please:

PS: Use these tiles outdoors only if the surface is flat and enclosed. You can use interlocked cement blocks otherwise.

|

Just a thought.. how about placing thick rubber mats? like this one? These are available as door mats and I think it is available custom size. Maybe two 2-feet wide strips would do for the tyre track.

This has to be somehow fixed to the floor, preferably bolted down.

Quote:

Originally Posted by Blow Horn Ok

(Post 3095208)

Else you can place 2 chequred metal strips of about 1ft wide on the vertical path where the car's tyre would come in contact. You could easily screw the plate by using flat head stainless stell screws at several places.

|

Metal checkered plates are slippery as hell and will offer even less grip than the tiles that are present right now.

The best thing for outdoor driveways is to use either concrete interlocking blocks or recycled rubber pavers. Concrete blocks are easily available, not sure about the rubber pavers though.

1.Since it would be very cumbersome to change the entire flooring, how about trying those small rubber speed bumps like the attached pic.

I don't know how effective this solution may turn out to be.

But I think you can install these at 2-3 places across the stretch so that the wheels have something to "hold on" to while going up or it can also prevent you from sliding down in the unfortunate incident of the vehicle slipping down.

2.I don't know if this is possible or not but you can ask some one if there exists a procedure to remove the glaze from the tiles and make them rough?

Do let us know what you do about it.

-Bhargav

Thanks for the suggestions.

Quote:

Originally Posted by Blow Horn Ok

(Post 3095208)

You can paste strips of tiles/granite of about 2 inch wide horizontally across the slope at a distance of 8-10 cms to gain traction.

Else you can place 2 chequred metal strips of about 1ft wide on the vertical path where the car's tyre would come in contact. You could easily screw the plate by using flat head stainless stell screws at several places.

.

|

Yes, it will become dirty if we do so.

Any idea about the grip of checkered aluminium plate when wet?

Quote:

Originally Posted by DCEite

(Post 3095499)

Thats a very very weird design. Tiling on slopes should never be done. Its not only inconvenient, its potentially dangerous as well.

Advise you to do away with it altogether.

|

Can't think of demolishing now. Also the bottom layer is hard rock. Cannot pave thicker materials. It may affect the slope.

Quote:

Originally Posted by bejoy

(Post 3095531)

Just a thought.. how about placing thick rubber mats? like this one? These are available as door mats and I think it is available custom size. Maybe two 2-feet wide strips would do for the tyre track.

This has to be somehow fixed to the floor, preferably bolted down.

|

Quote:

Originally Posted by Octane_Power

(Post 3095568)

1.Since it would be very cumbersome to change the entire flooring, how about trying those small rubber speed bumps like the attached pic.

I don't know how effective this solution may turn out to be.

2.I don't know if this is possible or not but you can ask some one if there exists a procedure to remove the glaze from the tiles and make them rough?

-Bhargav

|

Thinking of similar remedies. Rubber mat will make the place dirtier & difficult to clean.

Any idea from where can I get those strips?

I guess the glazing cannot be removed. It's not just a coating. Vitrified tiles have the same nature throughout the structure.

Quote:

Originally Posted by BuildUpGypsy

(Post 3095578)

Thinking of similar remedies. Rubber mat will make the place dirtier & difficult to clean.

Any idea from where can I get those strips?

I guess the glazing cannot be removed. It's not just a coating. Vitrified tiles have the same nature throughout the structure.

|

Yes rubber will make the place dirtier but I suggested you the rubber speed bumps. They won't get dirty.

http://www.glenrock-group.com/index.htm http://www.roadsafetyitems.in/index.php?itemID=9089

Here are two links of manufacturers of such speed bumps. One is in kerala itself. You can contact them and check out.

And as far as i know they aren't completely rubber. They have some other constituents too. So it will last for a lifetime that I can assure you.

-Bhargav

I guess, for a permanent solution, you need to take off the tiles at least at the place where the tires tread and concrete it instead. Cement bricks too tend to be slippery, but definitely not as slippery as tiles.

Jugaad? How about tar anyone? Tarring just the contact patch? And, will it make any difference entering in reverse?

Quote:

Originally Posted by DCEite

(Post 3095499)

Thats a very very weird design. Tiling on slopes should never be done. Its not only inconvenient, its potentially dangerous as well.

Never seen anything like this before.

|

Guess it's a common practice in Trivandrum to pave the car porch like this.

Had been to a relative's house near Trivandrum a couple of years back and faced the same problem, on a rainy day. It took me more than 7 or 8 attempts with wheels getting locked and slipping. The black marks made by my car tyres are still there.

Quote:

Originally Posted by thoma

(Post 3095661)

And, will it make any difference entering in reverse?

|

Initially i tried going into that car porch in reverse but failed. Guess only rear wheel drive cars will benefit going in reverse for such situations.

We had the exact same problem when building our house in Pune. The entrance slope was the same, and builder wanted to put polished kota stone for paving the slope :Shockked:

The flat floor of the parking inside was already of polished kota, so he was going to use the leftover kota plates on the slope. Fortunately I found out in time before paving.

Solution was simple, invert the plates so that the polished side went facing down into the concrete and the rough unfinished side faced upwards. We also staggered the edges (like a zigzag) to give extra bite to tyres.

Maybe you can repave the with the same tiles to keep the look, but flip them over to get the unfinished side facing up.

Another option could be to cut slits at a 2" interval diagonally and a straight border on both sides. Do two tracks to approximately 1.5 to 2 feet wide to cover each side of the car so driver does not have to concentrate much on keeping vehicle on track.

The vertical rows will serve as channels for rain / washing water.

Once you measure this out and make adjustments and correct specifications, you can use a marble cutting machine to test out and a grinder to smoother out edges. If you have a lot of water flow and dirt which may clog the vertical lines then see if you want to try to extend every 3rd or 4th diagonal slit towards the inside to meet the vertical or straight line border of the other side (between the tracks).

To try the concept use 3-4 parts sand and1 part low grade cement mix to make diagonal speed breakers at a 1.5 foot interval. These can be removed easily - ask a contractor for the correct temporary mix which will not leave marks and this could be a Do It Yourself.

If you don't want to drill slits then evaluate alloy strips that can be bolted down diagonally at 6 to 8 inch intervals for the troublesome stretch only.

| All times are GMT +5.5. The time now is 22:40. | |