Team-BHP

(

https://www.team-bhp.com/forum/)

I did look for used old school G for sometime and came across Tempo 290 GTD video, I think its this one

https://www.youtube.com/watch?v=5C2iSJbDCKU

With information I could gather online, Gurkha had all the needed hardware on which I could build on. I had few concerns like safety, steering angle etc, interior seemed doable though. Came close to buying Gurkha Extreme, then "GURKHA 2020" happened:

All my primary issues were addressed and it looked good too, incidentally it had same BHP as 290 GTD.

Booking:

After what seemed like long wait Force finally launched it, booked it on 30-Sep-2021, no test drive, actually I don't remember seeing any Gurkha in real life, as I said in other thread I was happy they made it . After transferring the advance online, I just sent below Whatsapp message to sales rep at Kshatriya Motors Mysuru.

Quote:

2021 Gurkha Booking Details

Color : Green

Acc : Roof Rail, Rear Ladder, Windscreen Bar

|

Test Drive:- Test drive vehicle came 15-20 days after booking, dealer sent it to my hometown.

- Took the opportunity to inspect drivetrian, suspension and rest of the hardware.

- Was happy with heap of metal I was getting for the money.

- Front axle guard and rear door step was damaged from previous test drives.

- Rear step needs to be made foldable for off-roading and felt current axle guard contraption had no place on this vehicle.

- Stock Alloys did not look great, removed it to inspect offset etc but there was no markings on the wheel.

- Took short test drive, tested all the functionally, engaging diff lock was cumbersome, saw opportunity to break it and make it better.

- Vacuum assisted clutch was very smooth, steering was light, braking was inadequate, it is better to be on cautious side in corners.

Planned Changes:- I booked vehicle with steel wheel so changing tire and alloy was on card.

- Was not happy with available A/T and did not want aggressive MT.

- Luckily saw Facebook post about RenegadeŽ R/T+ for sale, tires were from same 2021 batch.

- Booked 5 and got it delivered in 3rd week of Oct 2021, I think this is from same batch and source Manuuj got his.

- I had not told anyone in family about Gurkha, cousin who visited my man cave caught me, saying what are new jeep tires doing here.

- It was a long hunt for Alloys, I wanted something light and rated for offroad in similar sized vehicle, with Gurkhas old school PCD and center bore it was almost impossible.

- Finally made choice, getting it was hassle though, alloys arrived in November 2nd week, just couple of days before delivery.

RenegadeŽ R/T+

Delivery:

Delivery:- I was informed that vehicle would be driven from factory to showroom, I was not happy.

- Spoke to Force personal for alternative option, given a choice plan was to make a road trip in 124 to get the DAWG.

- Tow truck was expensive, trucking was risky, with lot of assurance for Force motors, I decide to go Force way.

- As soon as the vehicle left the plant engine and chassis number was shared.

- Vehicle arrived on November 18th, delivery was smooth, did only basic inspection(going back without vehicle was not an option).

- Hated the photo shoot though and requested not to share pictures on Force social media.

First Drive:- Drove out looking for fuel station, stopped at the first bunk few kilometres away.

- There is no remote open for fuel lid, so got down for the fill.

- As soon as I opened the door a gentleman stood in front of me and said he was following me to check on vehicle.

- He went around and peeped inside, had only one query how does this compare to new Thar.

- I told him if you are villager go for Gurkha, if you are towny visiting village occasionally go for Thar.

- Took sometime to get adjusted to light steering, on a tight turn rear wheel was off the ground, overall it was fun 150km first drive.

Owner's Manual: Manual is detailed and complete with wiring diagram and all, just as I wanted.

First Causality:- On first drive itself front axle guard hit a stone lying on normal road, which was not even 5 inch high.

- Few days later had to take it offroad(what is normal road for DI), its large stone filled path and axle guard kept on bashing.

- Person sitting next to me was getting jittery saying OMG stone is hitting the engine even with vehicle so tall.

- Next day Gurkha was minus axle guard.

Bent guard:  Initial issues and fixes:

Initial issues and fixes:- Day 1, there was power steering oil leak, cause reservoir loose cap.

- Every time I used 4 wheel drive there was oil puddle in the parking, cause transfer case oil overfill.

- TPMS system showed wrong tire pressure and stopped working after few days.

- Fix was to let the air and re-fill, since reading was in-accurate, fixed it with minus TPMS.

- Handsfree Mic was playing snake and ladder on dash, moved it behind steering.

- Fogging of front indicator on hood, force is expecting replacement from vendor.

- Missing partition between front and rear seats, any bottle or items that roll are potential pedal hazard, fixed it with under-seat subwoofer ;)

Breather Junction: Breather from gearbox, diff's and transfer case are vented in engine bay at common location.

Leak Location:

Leak Location: Oil would leak here and drop below on chassis wiring, damaging insulation.

Likes

* Gurkha's 4x4 hardware, it's complete, any usability issue is one modification away.

* DIY friendly with access to parts catalog and service manual.

* Carries lot of MB design elements, which I am familiar with, already have list of swappable parts.

* Excellent support from Force sales and service team.

Dislikes

* Rear end design and lights could have been more boxy, looks bit Mahindra'ish

* Core chassis is well done, but all add-ons look aftermarket, deserve improvement.

Initial Impression:

* Have driven it in mix of slush, gravel and highway, it drives well even with stock steel wheel and Ceat tires.

* I feel Gurkha can be handful in tighter off-road sections due it's weight and size/height, this is more of over-lander than rock climber.

* Highway behavior is balanced, steady throttle in corners help, braking has to be pre-emptive.

* Engine revs to about 3.5K RPM, in 5th gear does about 142km/h on stand.

* 120 km/h is easily attainable, 135 km/h is the max I have seen slightly downward slope, 100-110 km/h is the best highway speed.

* 3rd gear should have been taller, in most overtakes I had to up-shift from 3rd to 4th in between.

* Front end articulation is huge, you can walk over large humps, but rear being fixy is bouncy.

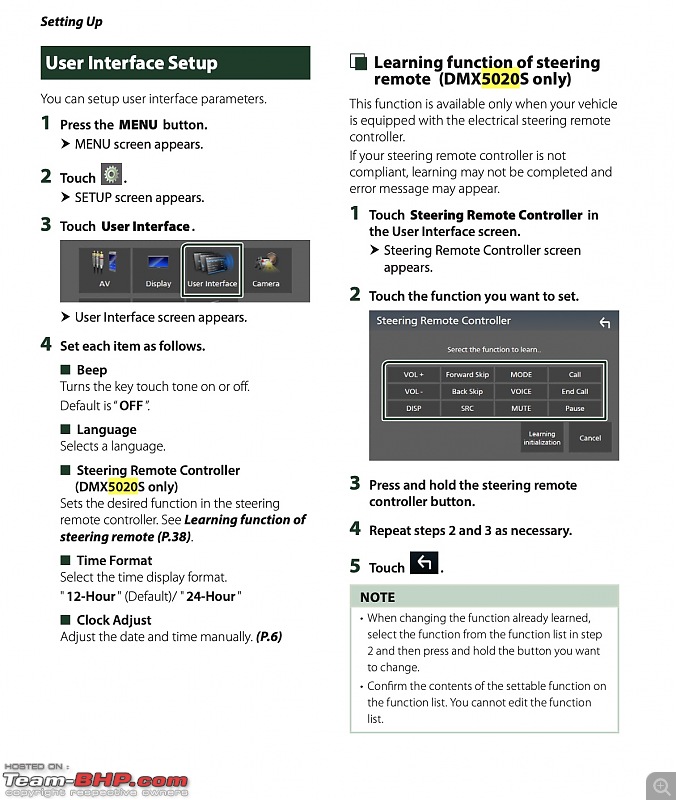

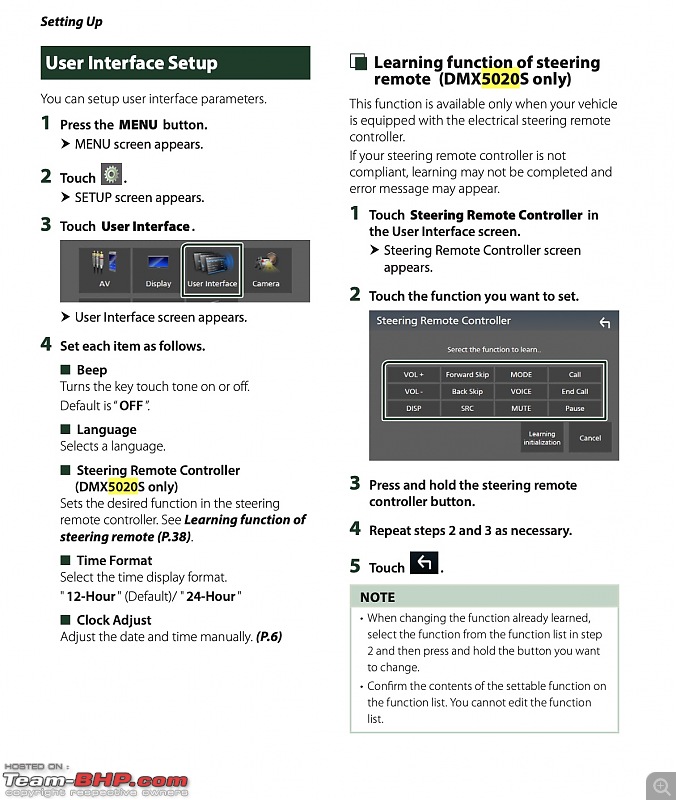

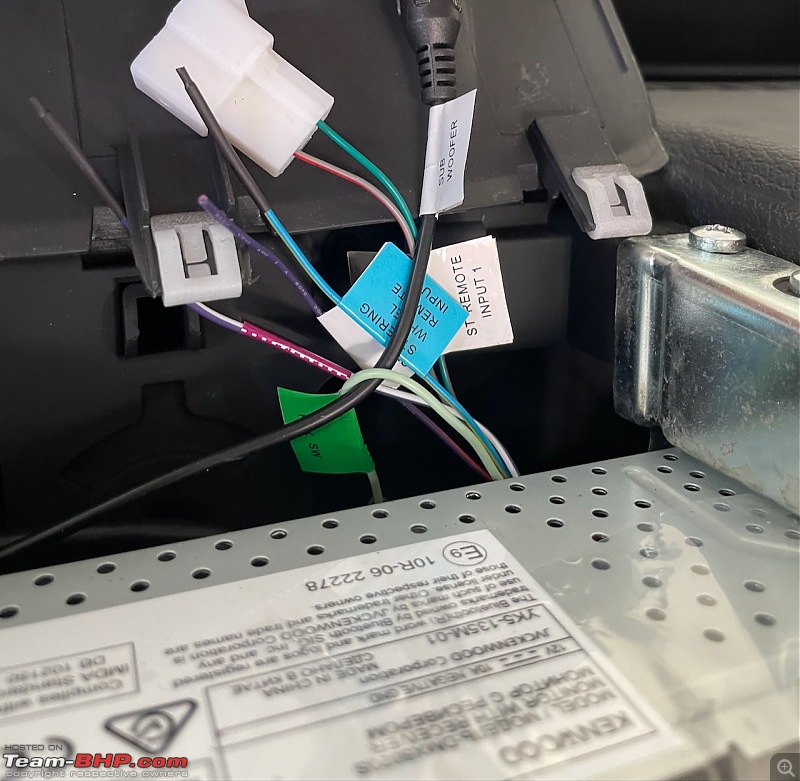

Kenwood 5020S in Gurkha is spec'd OK and works fine, being touch only it has poor usability without steering control, at least a volume knob should have been there. Checked 5020S specification and found it had steering remote control, incidentally only model in its series.

Steering Remote Specification

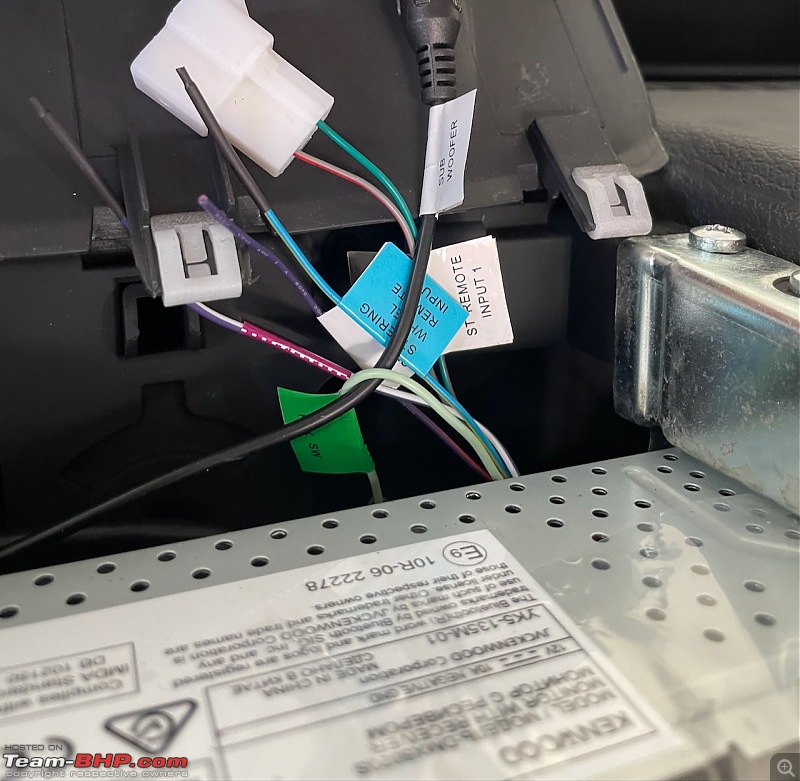

Steering Remote wiring

Plan:

Plan: Install steering remote control, front/rear dashcam and reverse camera in one go.

Parts:Implementation: Planned to route the rear dash and reverse camera via roof, which led to removal of most of side and top interior trims. I mounted the camera's on rear door, I needed additional reverse camera wiring to route via rear door jamb and up the roof and down to the dash.

Steering Remote  Rear dashcam & Reverse Camera

Rear dashcam & Reverse Camera

Interior Notes:

Interior Notes:- Core color of Dash is mostly BlueGrey like the transmission tunnel, but painted black.

- Plastic quality is not bad, but there are some assembly jugaad specifically in B pillar.

- Dash cross bar is not painted and there was some surface rust.

- Its damped well from factory including roof, you will find engine and transmission area damped MB style.

- If you have 123/124/126 missing damping(Engine/Interior), Gurkha parts can be close to OE solution.

New Mic location & Crossbar

B Pillar:

B Pillar: Trim should look like this without any gap between seat belt hanger and B pillar trim.

Reverse Camera

Reverse Camera  Dashcam

Dashcam:

https://youtu.be/r_gr8xB85mc

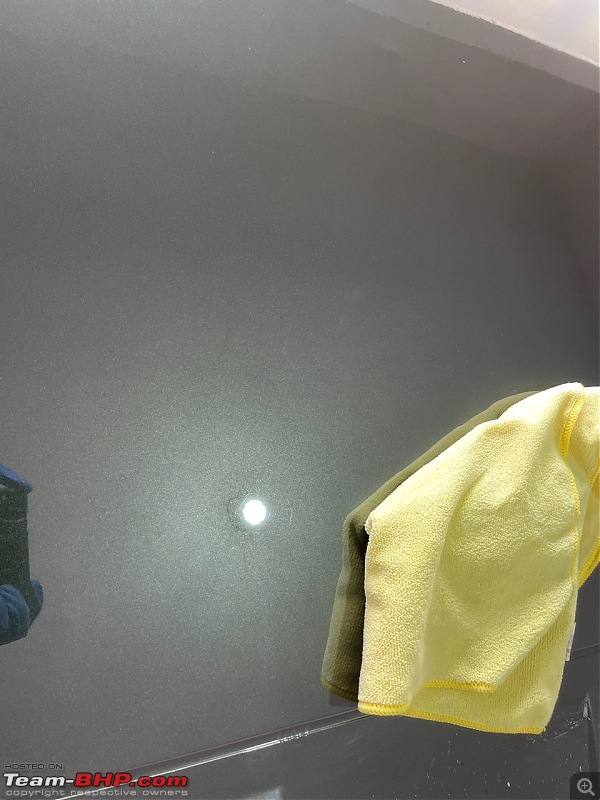

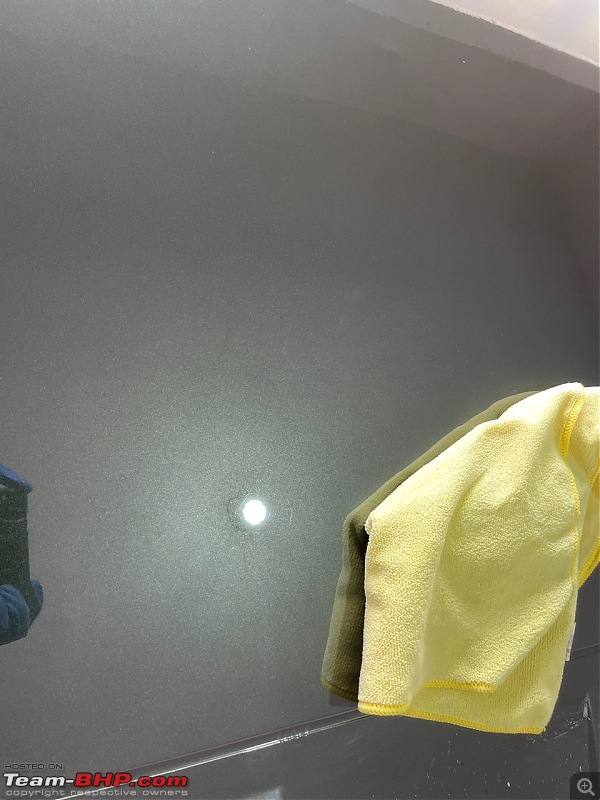

- Paint quality looks OK, really thin, you can find dirt nibs here and there, specially on roof.

- Every-time I drove on narrow estate road there were lot of scratches, fixing it I know is loosing battle.

- Thought of doing a polish and ceramic quote, but kept on pushing till I hit roof rail to a tree branch and it poped off.

- So it was minus roof rail and plus roof rack, planned to ceramic coat before fitting the rack.

- Did polish and ceramic coat including all glasses, it was draining specially doing the roof with indents.

- Had to remove all accessories like windshield guard, spare wheel mount, rear ladder etc.

- Since installing roof light was on cards, took time to modify windshield guard to route light wiring.

Sanded not finished: Someone had sanded the roof but not finished.

After Correction:

After Correction:

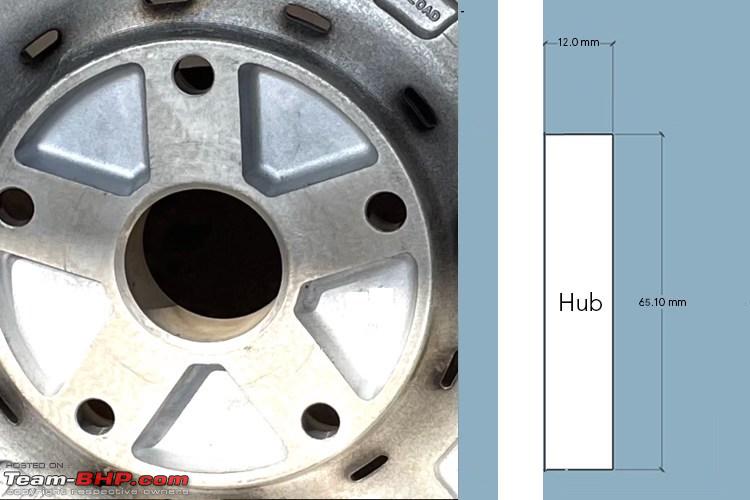

Did the first oil change after ~3200 kilometers. Its easier to change the filter after removing the wheel, took the opportunity investigate wheel fit and gaps.

R5 LE Specification: https://www.shell.in/business-custom...ct-leaflet.pdf

Its easier to change the filter after removing the wheel

Took the opportunity investigate wheel fit and gaps.

Any guess on what wheel ?

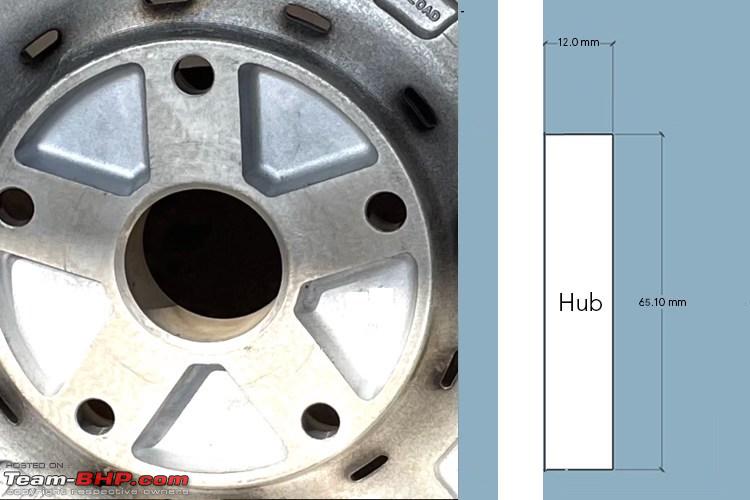

- Alloy wheel I had chosen needed hub modification or an adapter, did basic measurement to plan the best route.

- After reviewing various center-bore designs planned to go the hub modification way and requested for BS6 parts catalog from Force Motors which was obliged.

- Placed parts order in first week of December, parts store in charge was obviously intrigued on what I was doing with 15 days old Gurkha.

Design:

Flicked from

https://www.teslamodel3wiki.com/tesl...e-differences/ Parts List:

1) B008263341701 x 2 - Front Wheel Hub

2) B008323560801 x 2 - Rear Wheel Hub

3) A000023020542 x 4 - Oil Seal

4) A000023020532 x 4 - Oil Seal

5) B008329810205 x 8 - T R Bearing

6) A000023526102 x 2 - Gasket Axle End

7) B008323570080 x 2 - Gasket

8) A000023020512 x 4 - Thrust Washer

9) A000023020493 x 4 - Collapsible Bush

10) B008081802410 x 1 - Oil Filter

In January second week I got a call from Force motors saying parts are available, there were few missing parts like Thrust Washer, Collapsible Bush and Gasket Axle End. There was no ETA on when missing parts would arrive, planned to re-use Thrust washer & Collapsible bush and use flange sealant instead Axle End gasket.

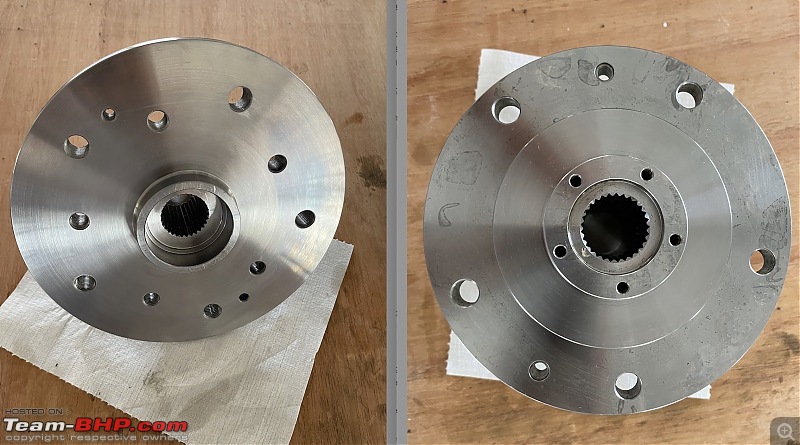

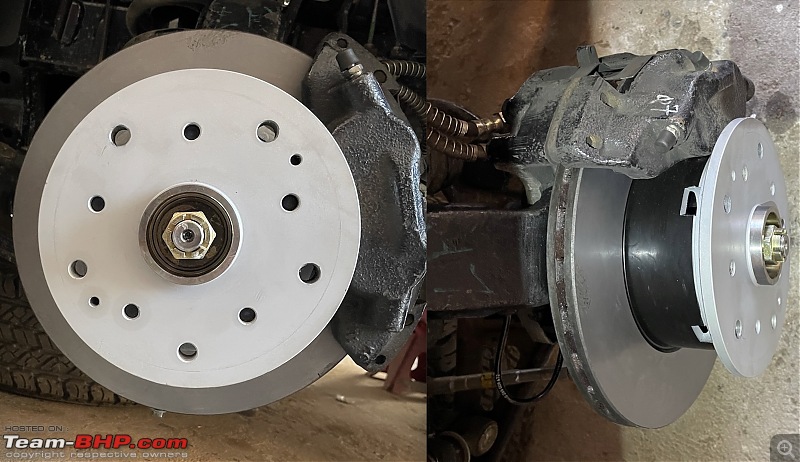

Front & Rear Hub: Hubs are same between BS4 & BS6, there is one minor difference with front hub.

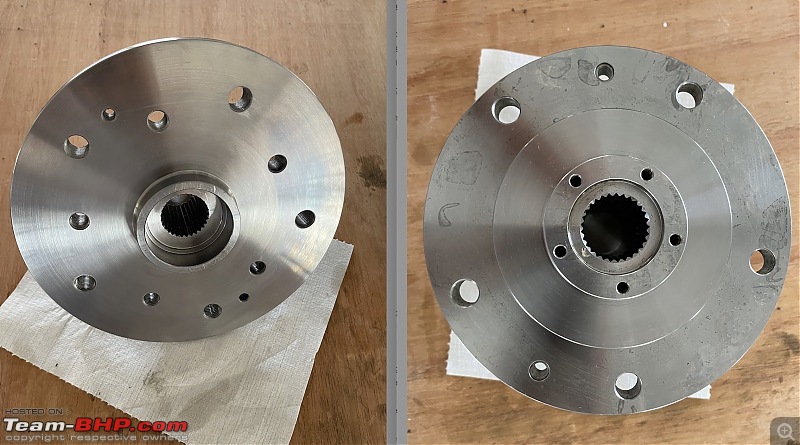

Hub Cutting:

Hub Cutting: Needed a good machine shop with precision lathe, this time instead of contacting tuner friends, spoke to Mannu who runs SunShine metal refinishing shop in Hebbal Mysuru. He suggested Mr Mukthar Khan and specifically said he has good HMT LB-17 lathe. Booked an appointment and visited the shop next day, it was pleasant surprise, located in isolated shed doing odd precision prototype job. Lathe was relative clean and spun like top, I was surprised to see owner had spent time

scrapping.

Front Hub finished:  Cutting Rear Hub:

Cutting Rear Hub:

Hub face to wheel mount on rear hub is about 11.5 mm and 12 mm in front hub. So planned to keep it 12 mm on all four. While cutting though Mukthar Khan measured 12.2mm in one front hub and 12.4mm in another, so kept 12.4mm in front and 12mm at rear.

Final Product: Mukthar Khan is well experienced did excellent job with alignment and cut. Took about 2 hours to cut 4 hubs.

Thread moved from the Assembly Line. Thanks for sharing!

Going to our homepage tomorrow :thumbs up

Wow, the 3rd Gurkha story in 2 months at t-bhp:loveit

This one too looks to become a page turner like the other two, am sure.

Congratulations on the ride! To me, this is the best shade the Gurkha comes in:Cheering:

Here is wishing you many lakh kilometers with the beast! Go ahead, unlock the adventure box!

It was time to take the plunge, was feeling lazy though

Jacked up and ready to go

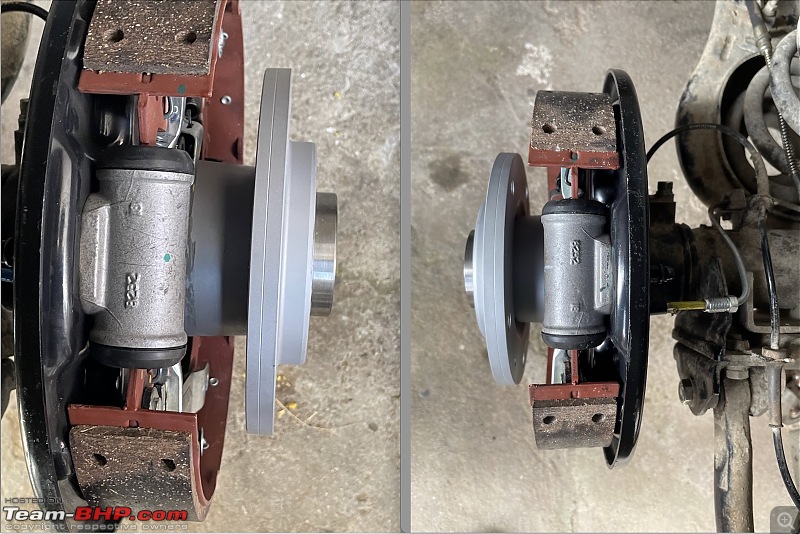

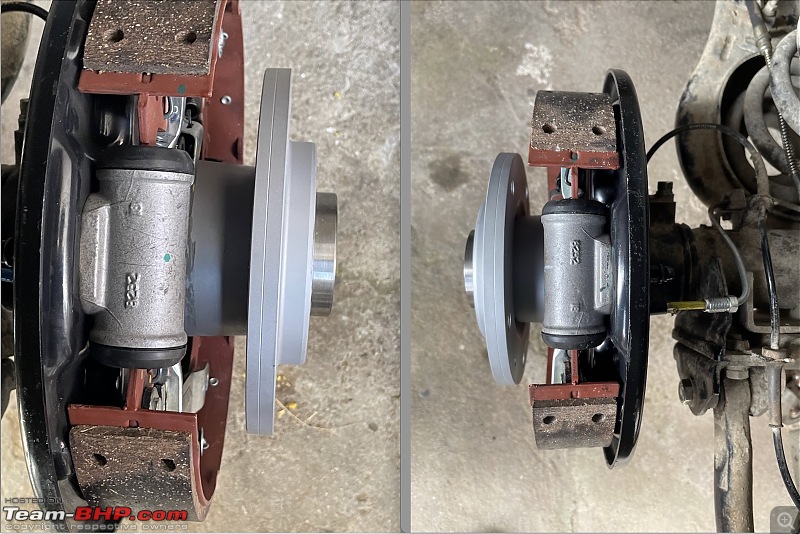

Rear brake assembly:

Rear brake assembly:  Removal:

Removal: To remove rear hub brake lines needs to disconnected and parking cable detached.

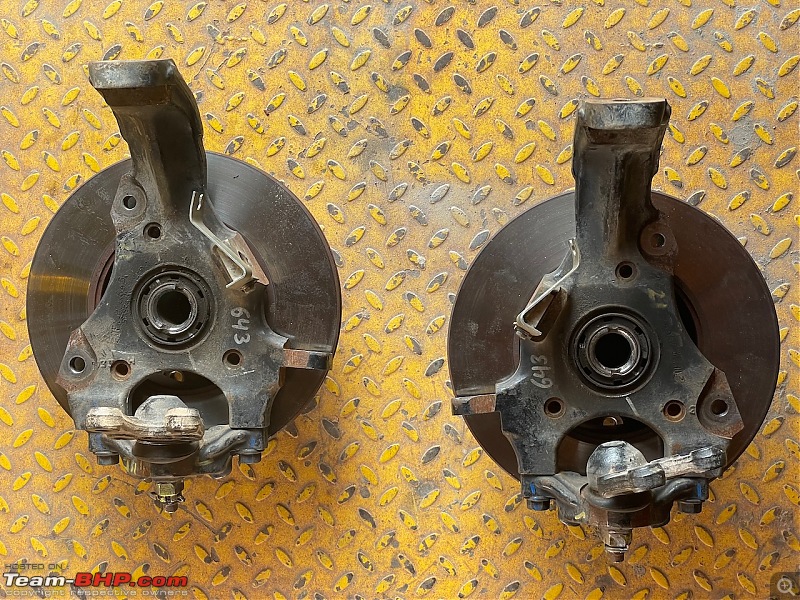

Rear Axle:

Rear Axle:  Dismantle Jig:

Dismantle Jig: To dismantle hub, you need jig as shown in top corner, I just used wheel itself as jig.

Lock Nut Tool:

Lock Nut Tool: Had to make a tool to get the lock nut out.

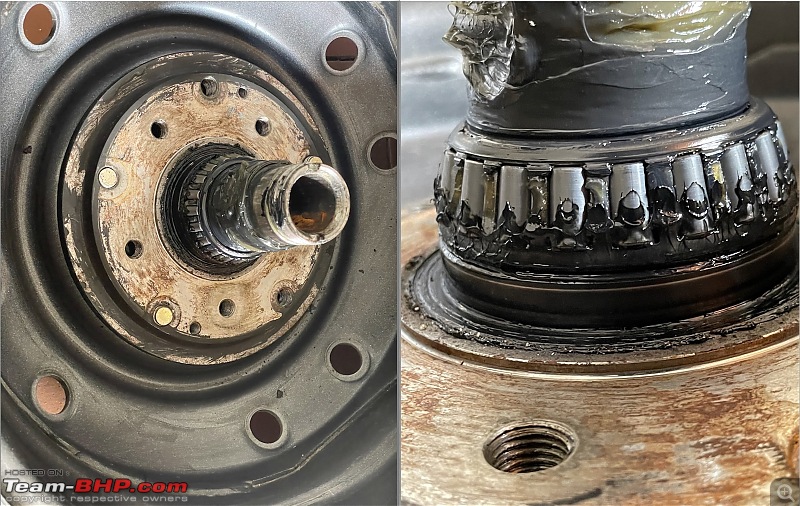

Hub Split:

Hub Split: Race & Grease was in good condition.

Hub Rust:

Hub Rust: Cleaned hub rust as preparation for paint protection.

Re-Finished:

Re-Finished: Painted and baked hubs before re-build.

Hub End:

Hub End: Before and After

Hub Parts:

Hub Parts: Spacers on top left corner is front hub only rest are same. Front and rear seals are different with different part number, front seals are better with double lip so used it for both front and rear.

Assembly Done:

Assembly Done: It's just putting all the bearings in same order as removed. The outer seal is on the axle so it's better to cover hub till assembly.

Axle Flange:

Axle Flange: Cleaned and ready for assembly.

Hubs In:

Hubs In:

Brake Drum Mount:

Brake Drum Mount: Drum mounted to check alignment, if you are doing this it would be more accurate to do final cut with drum mounted in lathe.

Brake Drum Surface:

Brake Drum Surface: Painted the drum wheel mount surface to remove old wheel indents.

Rear Axle End Cap:

Rear Axle End Cap: Center bore of 65.1mm is pretty close you need to loose about 0.5mm on end cap, also change the stock bolts. I used button head screws to avoid using ring washer, had to grind it to match the clearance.

Rear All Done

Rear All Done  Test fit

Test fit Rear Wheel Test fit to check the clearance.

Materials

Materials- GreenC RustOust result match Krud Kutter MF326

- Rust-Oleum 249340 High Heat Primer

- Rust-Oleum 248904 Automotive High Heat Paint(Flat Aluminum)

- Berutox FB 22 Spindle bearing grease (one of those time when grease is expensive than bearing ;))

| All times are GMT +5.5. The time now is 14:37. | |