Quote:

Originally Posted by nkghai  OK the first real niggle, which is a bother. |

I am inclined to call it an ordeal but would still classify the happenings shared below as a learning experience.

A couple of posts back I had reported a niggle of a “thak” sound coming from the steering and had been advised to get the alignment done. Well most of us can’t sleep properly if there is an issue with our steed and same is the case with me. I preponed my wife’s arrival to Raipur to Sunday 20th Mar, with the added advantage that I could get Nanook repaired at a Hyundai outlet. Spoke to Hyundai a day earlier and fixed the time of 9.30 AM for the checkup. Started from home at 6.40 AM, a drive of 115 kms and reached airport dot on time, flight landed at exact 8.45 and we were out of airport premises by 9.15 AM and as per precision reached the Hyundai outlet at 9.30 AM. Obviously the first one to be there, but since the supervisor was informed of my supposed arrival, he was there. Told my lady to relax in the waiting room and assured her we will make a move within half an hour after minor adjustments.

A snap of Nanook starting its first repair work at 7100 kms.

The mechanic comes at 0945 hrs, no job card opened and he was immediately assigned to check my gaadi for the fault. One small demonstration to him and he confirmed that the thak sound was indeed there and also confirmed it is the steering shaft joints which need to be tightened and not the alignment. Abhi do minute mein ho jayega Sir. Happily informed my better half that just few more minutes.

Then things started happening.

To get to both the upper and lower joints of the steering column, they have to open the dashboard below the steering as also on the right side. Took some time as the factory fitment is very snug. Now to reach for the steering joints is a pain. These are located at vey inaccessible places and cannot be even seen in the dark. Also Hyundai had no inspection lamps so it was difficult with mobile torches being used to see and adjust the spanner.

They found the joints fully tightened and opened the lower end completely and took it out. So the upper joint was connected and lower joint was free and it was pulled inside the cabin closed to the brake pedal and they moved the steering wheel full left and right to see what is the problem.

During one such turn, I heard a loud kritch sound and immediately exclaimed, kya hua? It was like the sound of those dashboard non metallic locking arrangements breaking. They rotated it again and no sound, but it was on the back of my mind. Finally after 45 mins they took out the steering shaft for inspection.

I now insisted on the Job card and it was then made immediately. The shaft was inspected and found to be perfect and the mechanic said that a small tape on mounting where shaft is tightened will cure the issue. I checked the shaft myself for play etc and found the same OK. Even the universal joints seemed fine. So white thin tape applied so that it fits well and all tightened and closed in next 30 mins. After fitment the mechanic was checking closely for the thak sound, which was not there but then once again I hear the kritch sound and got really worried. The vehicle was ready for test drive and the shop floor supervisor takes it out with me as co driver. He immediately notices that vehicle is instinctively going to left, does two to three start stop test on a flat road and is convinced of the left movement. In the meantime, I get a call on my mobile and it gets connected through Bluetooth but when I speak, the other party can’t hear me, so that means the mic was not working. It was then, when the supervisor tried to increase the volume, we realized that none of the steering controls were working. Even the horn had stopped functioning. Coupled with these facts was the issue that the steering was totally misaligned to one side which was clear from the fact that in reverse gear the screen with straight steering was showing the blue lines to extreme left. (Creta owners will understand as the blue lines on the reverse camera screen denote your intended path, with steering in its present position).

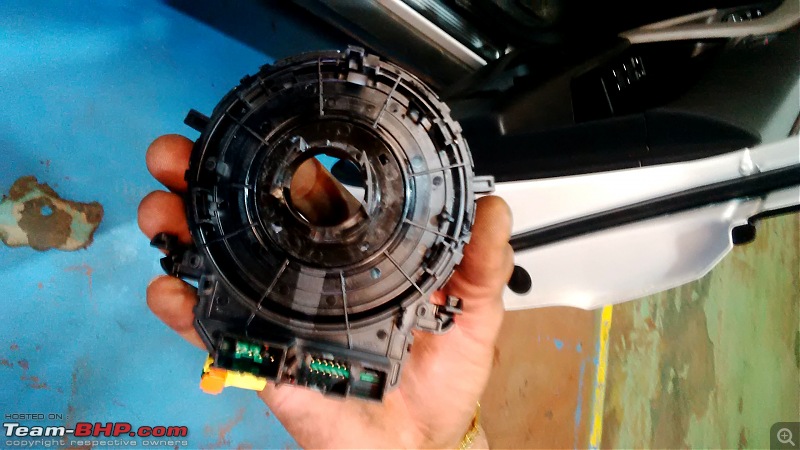

So something had gone wrong and we were back and the mechanic was told to get the OBD diagnostic, which he connects. The error displayed was “Steering airbag resistance very high”. The mechanic immediately concludes that steering clock has gone faulty. Initially I heard Steering lock and wondered how this could happen, then I rechecked and he mentioned that clock spring could have broken. Now I could make out what that kritch sound was. I immediately inform the supervisor that this happened during repair and the mechanic also confirmed that the sound was heard twice during repair only. What was done was done, my 15 mins halt was already 2 hrs and I told them to change the part.

15 mins of running around and the part is not available in their stock. Sh*t, being Sunday all other outlets will be closed and I had a sinking feeling. Luckily, the supervisor informs that this being Hyundai Customer care week, their main outlet which was around 30 kms away was open and the part was available there.

Great! So the plot was supervisor would send the mechanic there, who will get the part, come back and repair the vehicle. That would be cool 2-3 hrs before we get the part only. So I opined that why not I drive my vehicle to that main service station accompanied with the mechanic and he can repair it there only. Since both the service stations were of same person, it should not be a problem. It was immediately agreed to by the supervisor, so I get my wife and all her travelling luggage back into Nanook. The co-passenger seemed a bit peeved off but my concern was more for Nanook at that point of time. Driving a vehicle without horn in Indian traffic is just pure bloody irritating. If you don’t have a horn nobody will let you overtake as the rear and side mirrors in their vehicles are just for hair dressing.

Reached the new outlet and paper work was a breeze, with the accompanied mechanic really running around. Before going forward, would like to stress that during the drive the mechanic requested me not to tell the supervisor in the main service station that the clock had got damaged during repair. I asked him the following two simple questions:-

- Do you accept your mistake? He immediately said yes, and said it is purely his fault.

- What did you learn? He gave a good explanation that in the entire training he was never told that you could not rotate the steering wheel with the loose steering shaft and was completely unaware of it and he would be more careful and had learnt a very valid lesson today.

I was convinced, but only told him, I will keep quiet and not say anything.

So the new service centre supervisor comes and checks with his tab and confirms the steering clock fault and issues orders for replacement. They click all photographs and make a video of entire process for forwarding to Hyundai. Attaching pictures of steering after opening and the new clock both sides before fitment. Notice the pad on the dashboard

Simple tools. One more ring spanner was used which is not there in the photograph.

Once the new part was available the actual fitment took only 15-20 mins. Then started the software diagnostic and resetting procedure. The service centre in Raipur uses a Samsung Galaxy Tab which connects wirelessly to the vehicle and does the diagnostics. It is a DSC Software, how I wish I could lay my hands on that. After fitment, it was confirmed that there were no errors. Now for alignment the sensors were reset with straight steering, which was calibrated with reverse camera output. The ESP and other settings were reset to initial data, and presto I was told Nanook is ready.

Since it was a customer week they were having a customer meet and the mechanics and staff were constantly after me to sit and attend it. Having been satisfied and almost sure, I left Nanook for final check by the supervisor, who offered a free wash. So attended an impromptu customer meet and was give a small gift and eatables. Not very well organized though, but gave a good feeling. After 20 mins went back to where Nanook was being washed and got it done by my standards. Met the supervisor and he confirmed all was perfect and handed me the gate pass and since it was 3.00 PM already was in a hurry to go after thanking all.

We quickly stopped for a bite and started our return journey and that is where I noticed that Nanook was pulling to right. Extremely disappointed. I then found the problem was that the steering wheel was not fitted exactly in centric manner and was a wee bit left pointing when the wheel is straight, which was resulting in sensor trying to straighten it.

I did not have the energy and time (they close at 4.00 PM) to go back since I had a two hour drive ahead. So the situation now is that thak sound has gone but vehicle steers a little to right. I am quite unhappy with the supervisor for letting this happen as it is a simple thing and he could have checked. Also in my eagerness to end the ordeal, did not myself check thoroughly. Means another 220 kms drive to reset the sensor correctly.

Positives.

The fault for which I had gone, the ‘thak' sound in steering shaft got rectified.

I also had a chance to look at the complete diagnostic software and I checked the idling rpm about which I had posted some time back. The software showed standard idling rpm at operating temperature for 1.6. VTVT as 750 and my vehicle was 753, so perfect. One debate is settled that correct rpm is 750 only and all the electrical instruments are tuned to function at that rpm, meaning there is no battery drain.

Even though he made a gross mistake of spoiling the steering clock I was happy with the mechanics knowledge. He knew exactly which screw and nut to open and how. Never once did he look at the arrangement with a questionable look on his face. While parting he again apologized for his mistake and the fact that I had to spend that extra time because of him. I just told him, only people who work make mistakes and as long as he has learned something today, I am ok with it.

Negatives.

I have a vehicle steering to right, so have to keep a firm hand on the steering even while going straight. Need another trip of 220 kms to get it rectified. If done correctly again not more than half an hour job. The lady may not accompany me since the last 30 mins job lasted almost 6 hrs, though knowing my passion she was very supportive.

Just read a post from Vishu2xll that it may be the universal joint. Hope my problem does not resurface. Vishu please inform your friend to keep an eye on shaft removal and not allow steering movement with loose shaft. Thanks buddy for sharing your information

Will keep you updated.

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(10)

Thanks

(10)

Thanks

(5)

Thanks

(5)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks