| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  878,918 views |

| | #661 | |

| BHPian | Re: ECU Remaps : About Tools, Software & Tuners! Quote:

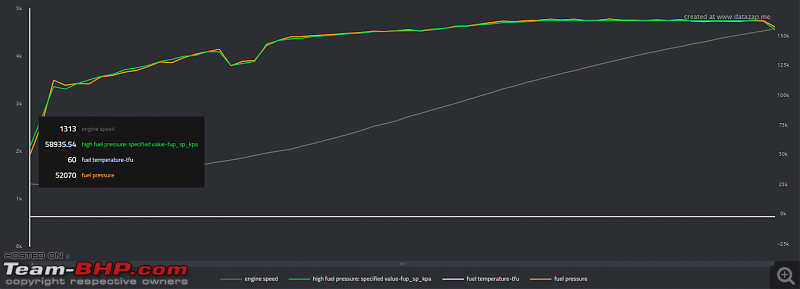

The above is the chart for fuel temperature at the start of the pull. It reads 60 degrees. This run was done thrice and posting the best chart. These are the data points with 3rd gear selected and from about 1.2k RPM all the way till redline. With higher gear engaged you will be able to capture more data but the speeds are too high to be done safely, hence the 3rd gear.  This is the temperature at the redline, drop by 1 degree (do not know if it is a significant or not).According to physics your temperature should decrease with decrease in pressure, but here it is vice versa.  Another thing to notice during tuning is, the duty cycle of the fuel pump (not yet found the correct adv measured blocks for this VCDS). If say you have a St1 map, and the duty cycle of the fuel pump is at 70-80% then there is close to no room left for upgrades in the future.Duty cycle in laymen is how hard a device is working to generate a specific output. So if you are already at 70-80% at St1, then to get to St2, probably you will need to upgrade the fuel pump, because duty cycle is only going to increase as you tune more. So if you are pushing past 80 % the chances of failure increases. But if you are at say 50-60 then there is room to utilize for a St2 build. | |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Bsilver for this useful post: | dieselteen |

| |

| | #662 |

| Senior - BHPian Join Date: Apr 2008 Location: Bangalore

Posts: 1,610

Thanked: 2,556 Times

| Re: ECU Remaps : About Tools, Software & Tuners! Completed a Stage 1+ remap from Wolf Moto on my 2020 TDCI Ecosport done 44000 kms. The results are really good. The overall drivability and response has definitely improved. And of course, the thing pulls like a locomotive from 1600-1700 rpm onwards, which is the best part. I am generally a relatively sedate driver, and my driving rev range is between 1200 to 2200 RPM in the normal course. Prefer riding the torque wave of the TDCI engine, rather than trying to rev too high. The engine already had decent enough power for most city driving situations, but now it definitely feels more sprightly and free revving, with the tacho needle moving fast across the rev range. On highways, or when quick overtaking is required, the acceleration is pretty ferocious anywhere above 2000 RPM now (downright scary upwards of 2500 RPM), and I have to back off from the throttle quickly to avoid overspeeding. Overall, money well spent and provides a worthy midlife upgrade to an already brilliant car. Looking forward to some highway drives and enjoying this lovely machine for many more years to come! |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank arindambasu13 for this useful post: | praveesh4u, suhaas307 |

| | #663 |

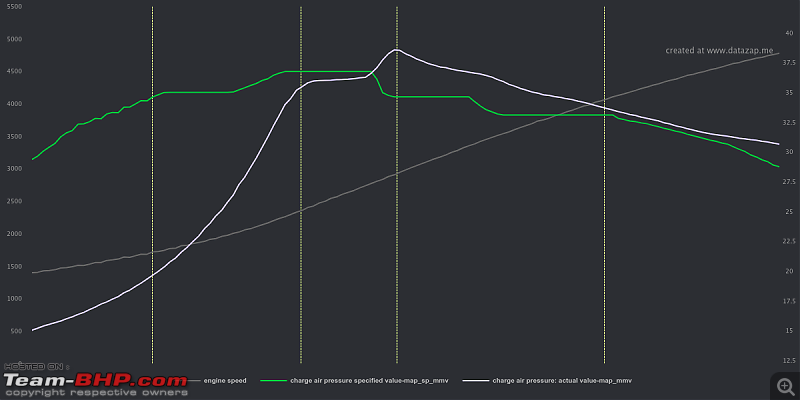

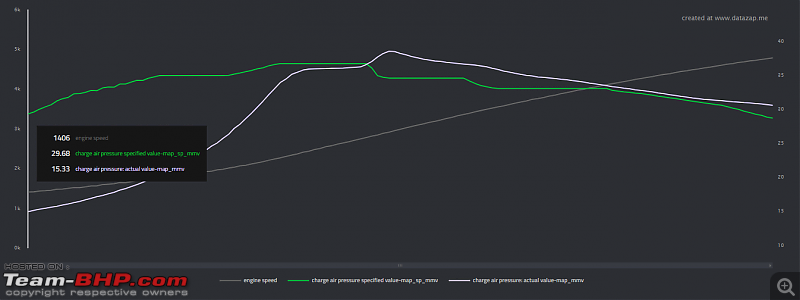

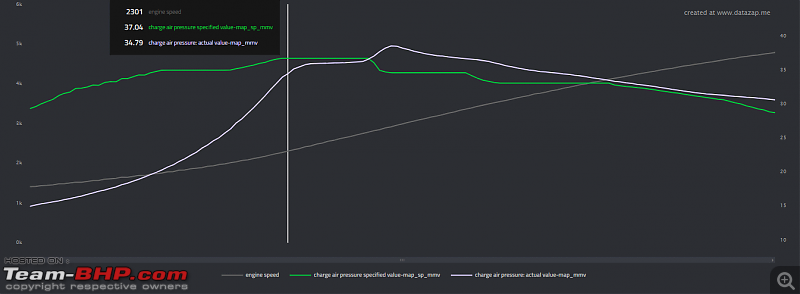

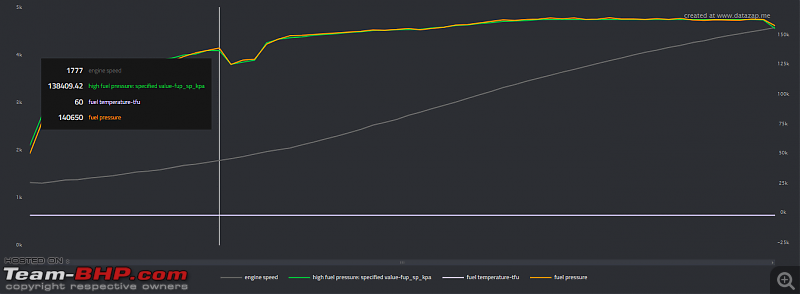

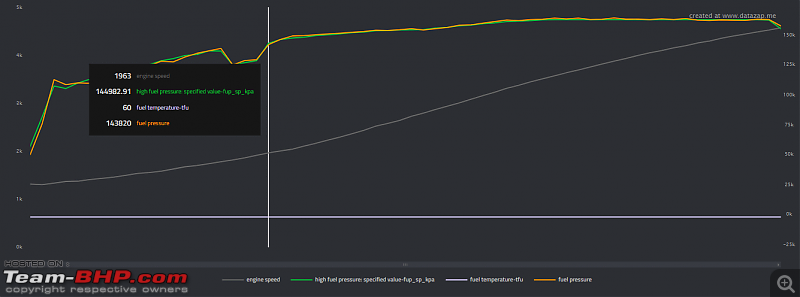

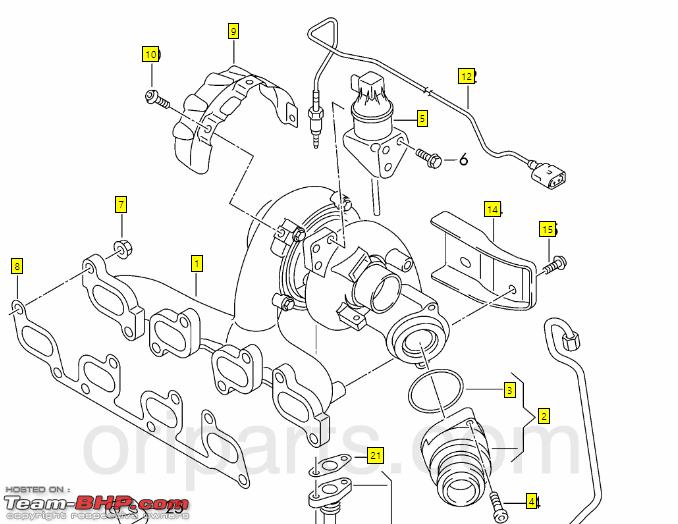

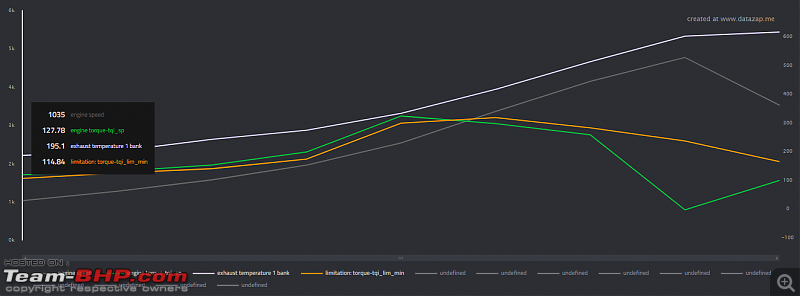

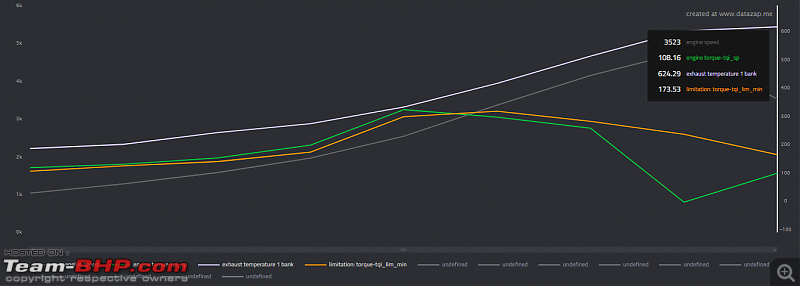

| BHPian | Re: ECU Remaps : About Tools, Software & Tuners! I data logged the turbo, fuel system, exhaust temperature and torque for my remapped Skoda Rapid 1.5TDI Manual, and each data log for every parameter was repeated 3 times and the best result was chosen. Third gear was selected for all the runs since I do not feel comfortable with the 4th gear speeds on my vehicle. The figures given to me by my tuner, BHP: 140-142 and Torque: 300-320. As mentioned earlier I would be doing the data log in my previous post in which I had mentioned about my experience with a Tuned Diesel. All of these was done on a sparingly used highway which is not yet opened to the public, but never the less I was extra cautious about everything. A friend of mine accompanied so that I could just focus on the road and not get myself or anyone else into trouble. Parameters monitored are as follows( through a VCDS cable): 1. Engine Speed present in all the charts. 2. Charge Air Pressure (specified value) which means what the ECU is requesting. 3. Charge Air Pressure (actual value) what is being delivered. 4.High Pressure Fuel pump (specified value) what is being requested by the ECU. 5. High Pressure Fuel pump (actual value) what is being delivered. 6. Exhaust Gas Temperatures. 7. Torque Values. These are monitored and the data was compiled in a website called www.datazap.me and converted to graph form.I have manually converted the boost chart to psi for better understanding as it was in kPA. This was done in excel.  This is the overall chart and I will be dividing this into specific markers where I felt that values are important. As soon as the logging was started, I just kicked down the gas pedal, and it was not lifted of until redline. Values at start of kickdown are below:  The requested was almost double at 30 psi and usually diesels can run higher boost as they do not have to worry much about preignition and various other factors. Charge pressure then increases rapidly as the turbo spools and when the engine speed increases and at one area you can see the ECU requests an almost linear amount of boost. The picture of linear request vs linear delivery is below:  The peak boost reaches at ~3000 rpm and the value is around 38.8 psi and requested by ECU is at around 35 psi. The picture is below:  After attaining peak boost at 3000 rpm the requested vs actual starts tapering and as well the delta between the both is lesser as the turbo has already spooled to a certain speed and at close to redline 30 psi is generated which is close to the 29 psi requested. Alongside all this I had data logged the fuel system as well at the High Pressure Fuel Pump level as it is more relevant. I has asked my tuner to adjust fueling so that I do not get any black smoke during acceleration and they told me they have cut the fueling in between the rev range. The data log of fuel pump is there in one of my post where the pressure is logged along with temperature as the fuel can be used by the tuner to cool the engine components. The fuel pressure specified vs actual in correlation with engine speed is shown below:  The delta between the fuel pressure specified value and the requested is really less as you can see the 2 lines are almost very close to one another. As said by the tuner, he cut fuel at one of the rev range and that happens to be at ~1770 rpm. Picture here:  And then he restarts the fueling a little before 2000 rpm and gradually increases the fuel pressure in order to deliver more, to account for the more boost produced. The restart point goes up and reached another point from which the fuel pressure is gradually increased. Picture here:  What I could notice is that the prior tune used to create considerable amounts of smoke but now since the fueling is tweaked a little I can see some amounts of smoke but not considerable one like a "Black Cloud". But still there is black smoke and would welcome suggestions from experts. But the idea of cooling the engine using fuel might be used here. Need to confirm. If we see the numbers on the boost chart at the point at which the fueling was cut, then we can understand the reason why black smoke is a thing for tuned diesels. So the point of cut off fuel is at 1777rpm to be precise and if we find the same rpm in the boost log we see that the requested boost by the ECU is not been delivered due to the reason that we do not have enough RPMs and the turbo has started to spool. Picture here:  Hence this is a completely satisfactory and numerically way to explain as to why the fuel pressure was cut off and reduced at that particular RPM. Prior to this adjustments, as mentioned on the top that I used to see a black cloud like smoke, which is now drastically reduced. The reason for the black smoke before was continued fueling into the engine when there is not enough air for it to combust all of the fuel because the turbo is not able to deliver the requested value from ECU which lead to the engine running richer and hence the black smoke. A better way and a more precise way to log this is using Engine speed vs Lambda which I will be doing in coming days to measure the deviation of Rich/lean combustion. But these graphs were to explain as to why fueling is the most important and not just to get a tune/boost which makes power in an inefficient manner. This carbon would eventually destroy the internals if too much of it is accumulated due to the tune, and would also result in blocking of the catalyst, increasing back pressure and causing damage, explains why some people remove it and do a downpipe, and many more problems, which I am glad to say is fixed to an exceptional extent with the Rapid, I am sure that little more fine tuning would reduce these levels to minimal as well, which is being worked upon. Now below is the log of the exhaust temperature and torque. Exhaust temperatures increase exponentially with increase in power, and will eventually destroy the turbo if they get too hot. The exhaust temperature was measured on VCDS but then the thing to note here is the placement of the sensor. Usually the exhaust gases temperature are in between 500 to 800 degrees Celsius and there is a detailed thread on the same in TeamBHP, link here: https://www.team-bhp.com/forum/techn...haust-gas.html (Maximum Temperature For Exhaust Gas) The placement for the sensor is before the turbo in the 1.5 TDI engines and at the exhaust manifold, the diagram of the same is here:  The label number 12 is the exhaust temperature sensor. Measuring the values itself is hard as the sensor is under immense load of temperatures, and uses a thermocouple for the same. The label number 12 is the exhaust temperature sensor. Measuring the values itself is hard as the sensor is under immense load of temperatures, and uses a thermocouple for the same. The drawback is that they produce a low voltage signal and this needs to be converted to higher voltage for the ECU to read, usually in between 0 to 5 volts. And we are measuring the result of the combustion and not what is happening in the cylinders, and all of these factors make the reading less accurate, but this is what we get from the factory and need to rely on it. The data log of the same is here(Thing to note: This was done in second gear so values are less, will do it in third in the upcoming logs):  As you can see at the kickdown in second gear the exhaust temperature was at 195 degrees Celsius, this was a stop of 10mins, which is normal. I did not want to hold till redline in second gear as I felt it was not needed as peak torques would be achieved much before redline. The exhaust temperature seems to be fine for an idling car and nothing to worry about, reference to the thread anything above 850 degrees Celsius would damage the turbo housing. The peak torque produced was at 332 Nm which is surely will give you the push in the seat type of feeling that too for a small sedan like Rapid. The peak exhaust gas temperature was at 630 degrees Celsius and I know that it would increase if we are constantly pushing the car hard, will only get to know in the 3rd gear log, but I am sure it would not cross 850 or so, fingers crossed till 3rd gear log on exhaust temperatures. Picture here of the peak gas temperatures:  Referencing the thread, if temperatures are too high (>900) then your remap might have fueling issue and it is better to log and fix it otherwise you may face problems with it. Peak torque picture here:  By deriving Hp from torque according to the measured graph we can get a graph of power curve as well, but I have done it only for peak torque value. Peak torque was at 2540 rpm as per graph and value was 332Nm, so formula is (2540 times 332)/5252 gives us 160Hp. This is not the correct way but just an idea to get as to what amount are you getting out of the tune. Dyno is a much more reliable, correct, safer way to do the same. The tuners claim was at 140-142 which I feel is a handful amount with just a tune, and air filter swap. That's it for now guys, experts please let me know if anything is wrong and suggestions to improve the tune further are very much appreciated. I will be logging the intercooler, lambda sensor in the coming days. Thanks! Last edited by suhaas307 : 20th June 2024 at 20:19. Reason: Spacing and formatting |

| |  (4)

Thanks (4)

Thanks

|

| The following 4 BHPians Thank Bsilver for this useful post: | audioholic, praveesh4u, rkv_2401, Siddarth_Ramani |

| | #664 |

| BHPian Join Date: Aug 2019 Location: Mumbai

Posts: 117

Thanked: 349 Times

| Looking for a little more performance from my 1.6 MPi Rapid My Rapid completed 5 years in May '24. It's been more or less smooth sailing for the most part, with occasional battery issues here and there, but nothing major. The engine is just perfect for the city. Being NA, it has plenty of low-end grunt for daily usage. Quite efficient too. It's on the highway where, post ~3.5k rpm, it starts losing a bit of steam. The most noticeable instance recently, and which planted the idea in my mind, was the beginning of the ghat section of the Mumbai-Pune expressway. Overtaking trucks traveling in whichever lane they please took quite a bit of effort and downshift+revving, earning me a rather distasteful look from my passengers. It didn't bother me much before, but post the addition of the XUV700 to our stable, the sweet pull of that 2.2 mHawk has spoilt me rotten. I would prefer a software solution over a hardware one, so a remap was the first thing that came to my mind. A few inquiries at Code6 weren't encouraging, and pouring through online forums didn't yield much either, this engine seemingly not being as mod-friendly as the TDIs and the TSIs. What are the options I should look into? Also, a follow-up question for folks living in Mumbai: if a remap is my best solution, what would be the best place to get one? Attaching a picture of my beloved.  |

| |  ()

Thanks ()

Thanks

|

| | #665 | |

| BHPian | Re: Looking for a little more performance from my 1.6 MPi Rapid Quote:

Cheers! | |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Bsilver for this useful post: | CapKoura |

| | #666 |

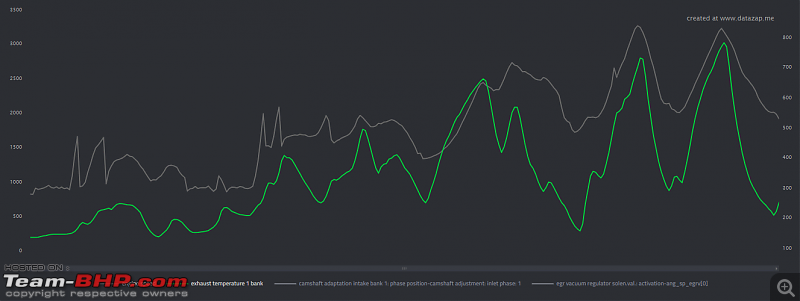

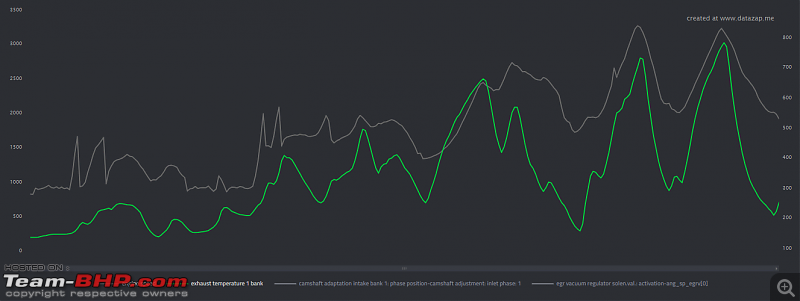

| BHPian | Re: ECU Remaps : About Tools, Software & Tuners! As I had told in my earlier posts I will be doing a detailed log on Exhaust Gas Temperatures in a tuned vehicle. In my previous post I have already covered what is the science behind the EGTs and how the location of the sensor plays role of the same. In this post I would like to bring your attention to the EGTs when cruising, and EGTs when locked in a gear. I logged my Stage 1 Skoda Rapid 1.5TDI manual recently, and have got an overall idea of what the tune is doing. So firstly with the basics, if the EGT sensor is before the the turbine and near the manifold then these temperatures are called turbine inlet temperatures, and if they are measured after the turbo it is called turbine outlet temperatures. If we are measuring the EGTs after the turbine we may account for a loss of 200 degrees which is ideally known amongst the community. There may be multiple sensors for an engine measuring the EGTs but I have done readings at Bank 1. So the sensor in question is before the turbo in my case and at the exhaust manifold, which is the turbine side of the turbocharger. So it is safe to say that the measurements which were made are the turbo inlet temperatures. All of these measurements were done on a closed highway which is constructed but not yet opened to public, and it was a two person method, so that it is safe for the people in my surroundings as well. Engine: 1.5TDI CWXC Manual Transmission Output Figures: 140Hp (claimed by tuner) but as per logs it is in the same ballpark. 300+NM of torque. I have done already done the correlation between the lambda and EGTs in my previous post. But let us dive into a little detail as to why EGTs play a vital role in your engine. Usually the first component to depart is the turbo, the reason being it is directly exposed to the exhaust gases of the combustion process. The lambda if too rich means is the direct resultant of the combustion in the chambers. The lambda goes rich in mostly 2 cases: 1. Under more loads (like towing). 2. Under WOT(Wide open throttle) So this is one part. The second part is the turbo which will need to bear this. Usually most of the people who are getting into tuning as of now, are mostly focusing on the power figures which they are offered without understanding the affects which it will cause on the engine and its longevity. Usually which part in the turbo will fail cannot be gauged and is subject to another field in Engineering called Design of Machine Elements. Let's not get to much into it, but the vanes at the turbine side, which are usually in square corners will fail first and taper off. The reason for this is that material is the thinnest at the edges of the vanes and due to the phenomena of specific heat this will melt due to the high temperatures. Now the result of this, the turbine wheel will go out of balance and cause bearing issues which may result in a shaft failure. In short, you will blow your turbo! One may ask what is the safe EGTs now for a tuned diesel. Usually many OEMs consider that 1350 Fahrenheit as a good number i.e. around 740 degrees Celsius. But then there is a reason why people get there vehicles tuned, so as per most of the forums and in the performance terms around 850 degrees should be the max and you should not go above this for extended periods. One more thing to keep in mind is that EGTs will drop very quickly by many degrees once you lift your foot from the throttle, so if you are doing WOT for say a minute (which I assume you will hit the top speed) then it is fine because your EGTs are climbing to 850 Celsius but staying there for around a few seconds only. But repeated exposure to such WOT cycles will definitely result in the above mentioned damaged. This log which is done was done after cruising normally at 70-80kmph and which I assume most of you would be doing on the highway and when you want to have some fun usually this is the speed where you start with for going WOTs. So first I was cruising normally for 5-10 minutes at 80kmph and then from about 1200RPM in 3rd gear I would do WOTs and then shift to 4th. So this was the method done and here is the log of the same: Picture here:  As you can see this was the graph and now let me show you the peak and the starting EGTs and peak EGTs. Start: Picture here:  Peak EGTs: Picture here:  Here is a play of the EGTs for the entire pull as a GIF(it would be played fast):  I had also done a log with varying loads as well and this was a big log and lots of data was captured during the same. So the picture of the log is here:  Played as GIF for the same here:  As you can notice that once we let of the throttle the EGTs begin to drop really quickly and the same can be told about when WOTs as well. My EGTs are a tad bit high considering that there will be some smoke for a tuned diesel, so a rich mixture, but if you have to keep a number in mind for the EGTs it would be 800-850 degrees Celsius. And this would be there for a few seconds and not even minutes, so bear this in mind. There is a discussion of EGTs on the forum to which the link is here: https://www.team-bhp.com/forum/techn...haust-gas.html (Maximum Temperature For Exhaust Gas) The combustion reactions are very spontaneous which can be directly explained by the temperatures climbing by triple digits in matter of seconds. So if anyone wants to tune there diesel, please keep this in mind and ask your tuner as well to keep this in mind. As per me, the tune which I'm running (would be mentioning name later for a in depth review) is very well engineered and tested. I have been using this for almost 15,000kms and there is no problem whatsoever. The log of the EGTs gave me a relief and also a limit to which I should not push the vehicle. That's it for the EGTs part guys, I would be logging the Intercooler as well for the vehicle, stay tuned! Happy Motoring! |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank Bsilver for this useful post: | d3mon, Siddarth_Ramani, ssjr0498 |

| | #667 |

| BHPian Join Date: Jul 2022 Location: Chennai

Posts: 61

Thanked: 107 Times

| Re: ECU Remaps : About Tools, Software & Tuners! Hi, has anyone done a Stage 1 map for Boosterjet (Baleno RS, or Fronx Turbo AT) or i20 N Line DCT/iMT? Quantum website claims around 20% gain to ~130hp and ~200NM. I see many posts on the 1.0 TSI, but very less for Baleno RS and none for i20 N Line. Also, in general, how do these maps work with automatics (Torque convertors and DCTs)? Does the TCU also need updating or does the new map work with existing TCU itself without any issues? Last edited by vvs29 : 4th September 2024 at 13:57. |

| |  ()

Thanks ()

Thanks

|

| | #668 |

| Newbie Join Date: Jul 2023 Location: Surat

Posts: 22

Thanked: 39 Times

| Re: ECU Remaps : About Tools, Software & Tuners! Are there any tuners for petrol cars? I'm looking for one for my Thar Petrol. Last edited by KarthikK : 4th September 2024 at 17:27. Reason: Typo fix |

| |  ()

Thanks ()

Thanks

|

| | #669 | |

| BHPian | Re: ECU Remaps : About Tools, Software & Tuners! Quote:

Happy Motoring! | |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Bsilver for this useful post: | vvs29 |

| | #670 | |

| BHPian | Re: ECU Remaps : About Tools, Software & Tuners! Quote:

Happy Motoring! | |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Bsilver for this useful post: | NajSaf |

| | #671 |

| Newbie Join Date: Jul 2023 Location: Surat

Posts: 22

Thanked: 39 Times

| Re: ECU Remaps : About Tools, Software & Tuners! Thank you, @BSilver, for the information. I've reached out to GT Tunerz and am awaiting their response. It's worth noting that their website currently lists only the Diesel version. Nonetheless, I hope they will respond to my inquiry about a petrol tuneup. |

| |  ()

Thanks ()

Thanks

|

| |

| | #672 | ||

| Senior - BHPian | Re: ECU Remaps : About Tools, Software & Tuners! Quote:

Quote:

I have a Torque Converter AT car that has completed 52000 kms after the first ECU remap. The TCU has not been altered, in fact, there seems to be no possibility in doing a TCU tuning for the TC car. I don't feel any jerks, and my driveability is not compromised because of the ECU remap and the lack of a TCU remap. In reality, the driveability has improved leaps and bounds. I just wanted a TCU tweak to simply make it shift a but earlier when I am driving sedately, which would have been a welcome change even without an ECU remap. If you have a TC AT car, just getting the ECU remapped is fine, at least that is my experience. Last edited by clevermax : 6th September 2024 at 13:31. | ||

| |  ()

Thanks ()

Thanks

|

| | #673 |

| BANNED Join Date: Aug 2024 Location: Delhi

Posts: 16

Thanked: 27 Times

| Re: ECU Remaps : About Tools, Software & Tuners! Greetings. Is there any information available about a possible ECU remap for the newer Thar Diesel (Post 2022). From what i have come to know only code6 is giving a remap but its a stage 2 map and i was looking for a stage 1 map. |

| |  ()

Thanks ()

Thanks

|

| | #674 |

| BHPian Join Date: Sep 2019 Location: Pune

Posts: 174

Thanked: 179 Times

| Re: ECU Remaps : About Tools, Software & Tuners! Hello Experts - I am planning to remap my Kodiaq TDI. I am looking for better acceleration and bit of thrill. What are the best options I have? |

| |  ()

Thanks ()

Thanks

|

| | #675 | |

| BHPian Join Date: Dec 2023 Location: Gurgaon

Posts: 34

Thanked: 49 Times

| Re: ECU Remaps : About Tools, Software & Tuners! Quote:

| |

| |  ()

Thanks ()

Thanks

|

|