I am not sure how many of you will be familiar with the term "Nodding Donkey".

But you might well be familiar with the sight of these things:

Nodding Donkeys are officially known as Pumpjacks. Not sure which official came up with that name, but Wikipedia says so. These contraptions are known under different names as well, such as: beam pump, walking beam pump, horsehead pump, nodding donkey pump (donkey pumper), rocking horse pump, grasshopper pump, sucker rod pump, dinosaur pump, Big Texan pump, thirsty bird pump, hobby horse, or just pumping unit.

And that is in the English language only. I am sure many countries have local names for these things. In the Netherlands, we call them "Ja-Knikkers". Which means as much as Yes-nodding.

I find these things fascinating. Very simple devices, come in quite a number of different varieties.

Just a basic diagram of how these devices work. Pretty simple as you can see. Not much explanation is required.

Nodding Donkeys have a bit of special meaning to me. Or rather bring special memories. My wife grew up in Barbados. A tiny island in the Caribbean. As you can imagine we have visited the island many times over the last 45 years or so. Also with our children (and these days grandchildren) On the island, they have some oil wells. Especially in the southern part of the island there used to be dozens and dozens of these nodding donkeys. Most of them are gone or out of commission these days.

But when our kids were little there were plenty around. And they were fascinated! They could not get enough of them. Whenever we got in the car to go somewhere they would get all excited. They would play, spot the first nodding donkey, who sees the most nodding donkeys and so on. My father-in-law, i.e. their granddad, used to take them around the valley where my inlaws lived, just to see the nodding donkeys!

Seeing a lonely nodding donkey somewhere out in the field, going up and down, slowly, but relentlessly, is somehow a bit of a hypnotic sight. These lonely mechanical devices bring up oil, 24/7 without any oversight!

When we lived in Kansas City I recall driving some 6-7 hours out onto the prairies to an oil museum. Somewhere in the middle of nowhere. As expected many different kinds of nodding donkeys!

So when I came across a "real working model of a Nodding Donkey" I had to have it immediately! Let us not discuss cost, because when you deal in important matters such as these cost is no issue. "Take my money" is the only appropriate amount.

It arrived the next day by courier.

It comes in this nice box, with some nice images on it. A lot of Chinese on the box too.

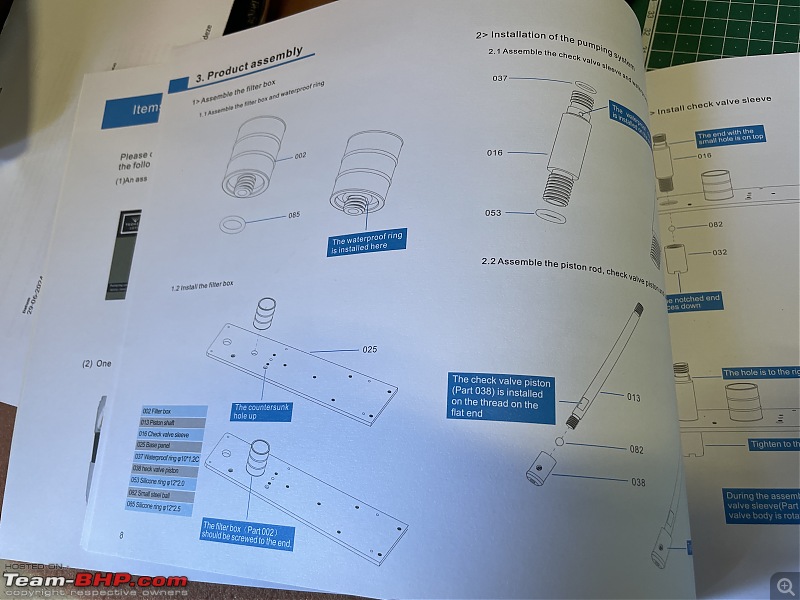

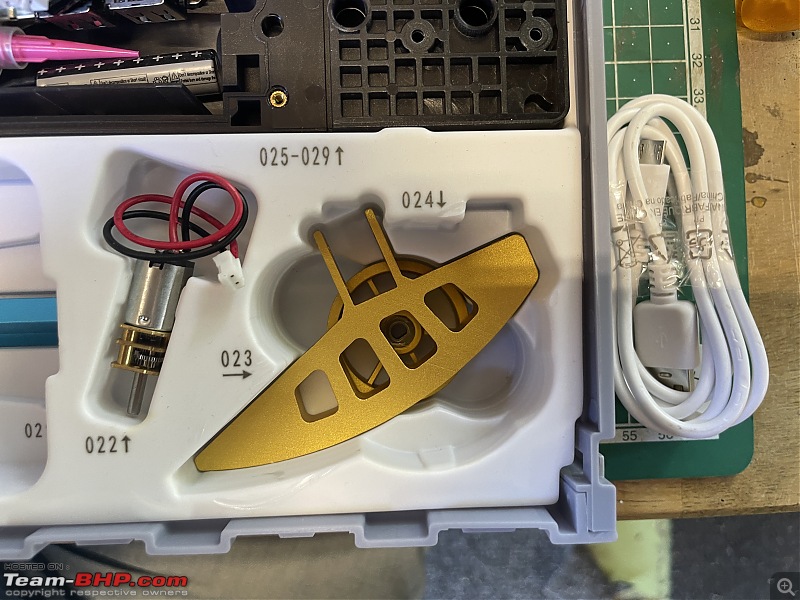

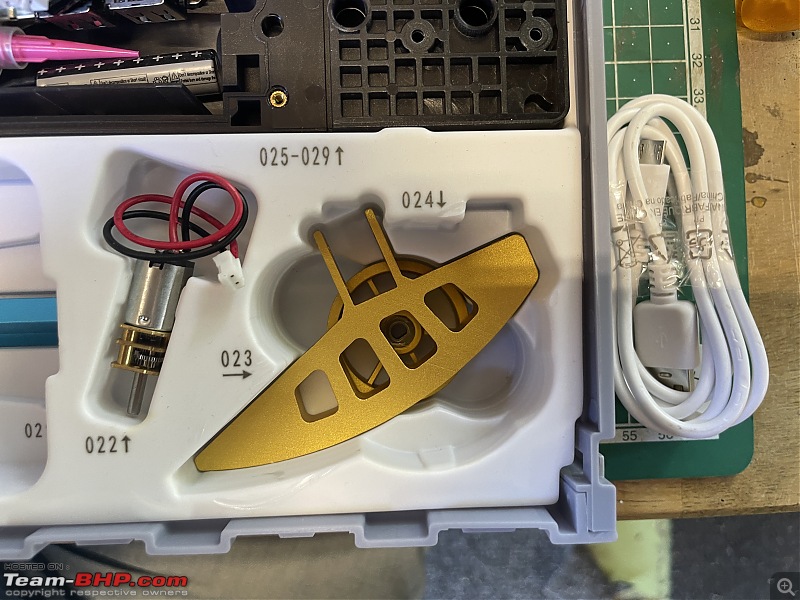

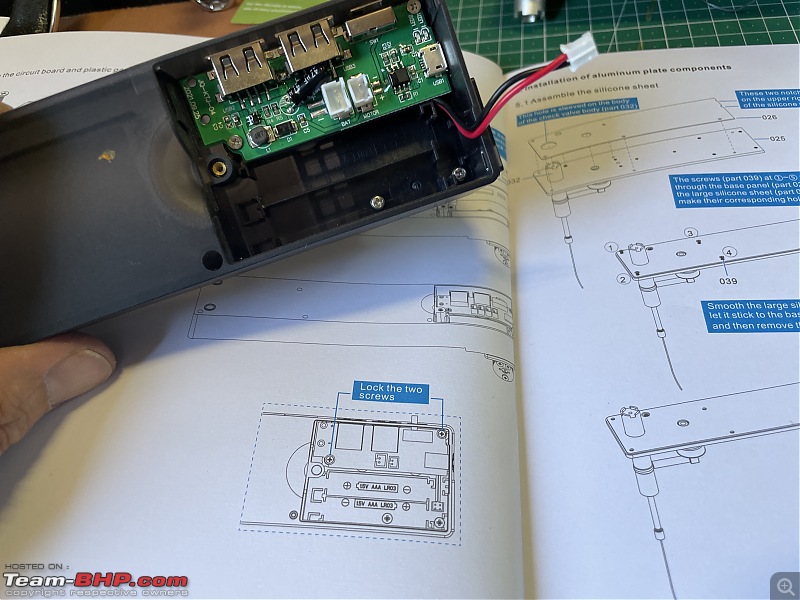

Things get even better when you open the box. Parts are all beautifully laid out, with numbers and a very thick assembly instruction book!

Me being an engineer and a terrible nerd, first thing is to read the complete manual front to back, of course!

The box is full of parts, hundreds of parts.

Also a box with all the small bits. Bolts, nuts, washers, O-rings etc. Hundreds and hundreds!

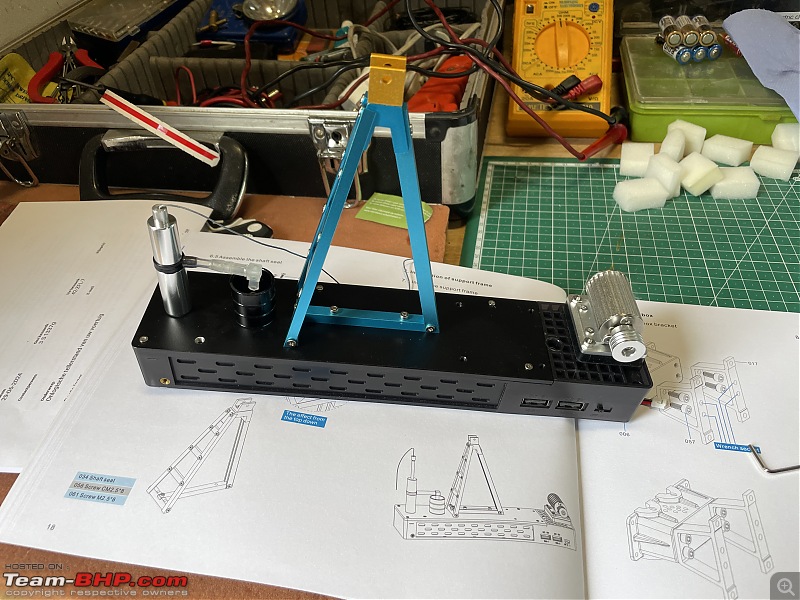

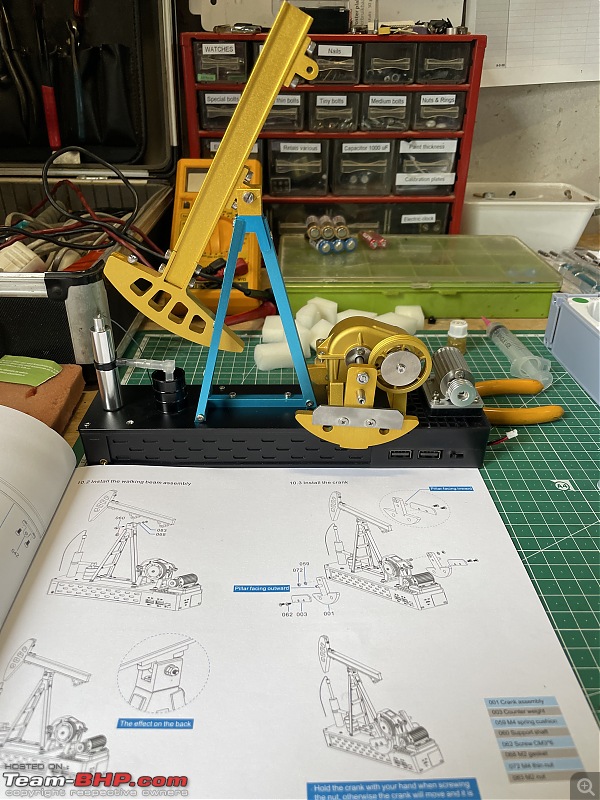

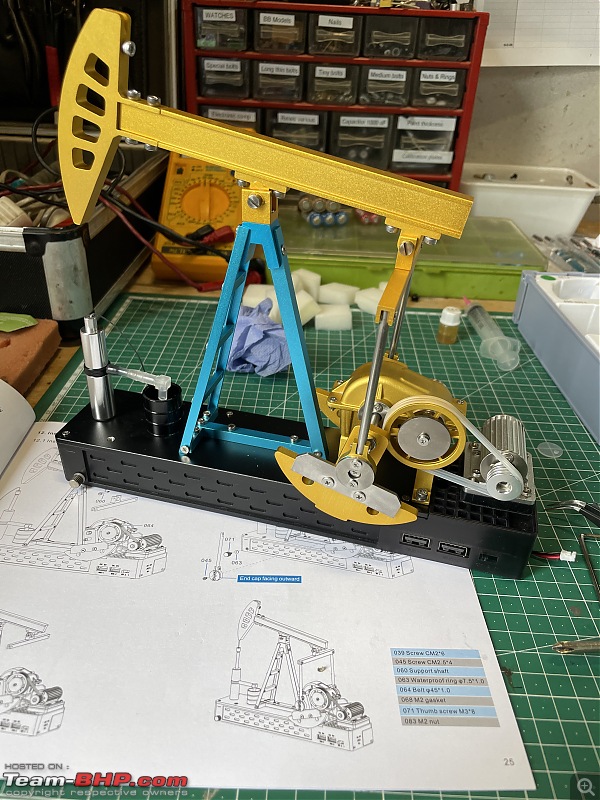

Putting the nodding donkey together is a fairly easy process. I will show you some of the steps. I have also made a video, posted towards the end, in which you can see it actually pumping!!

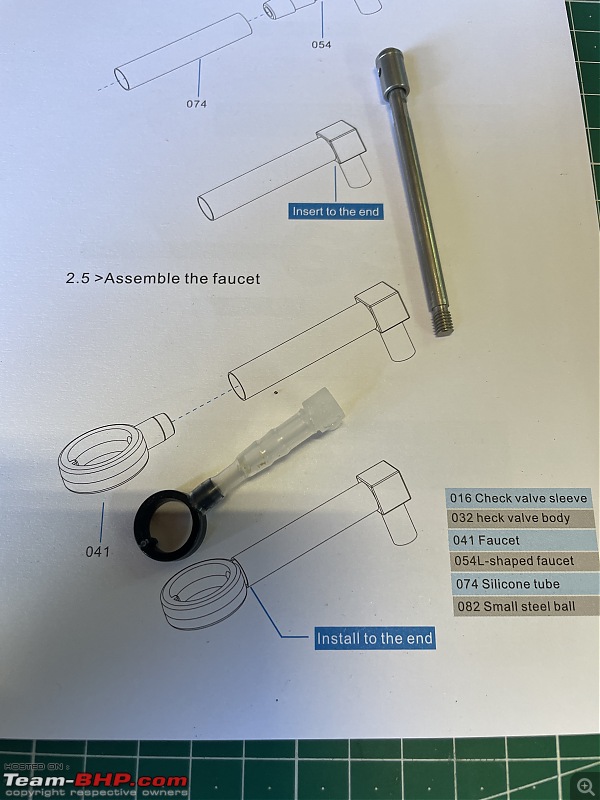

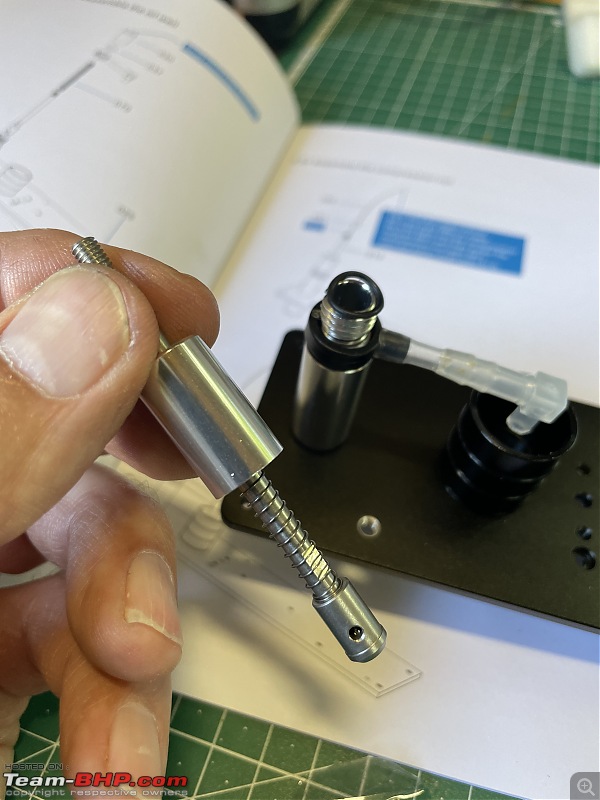

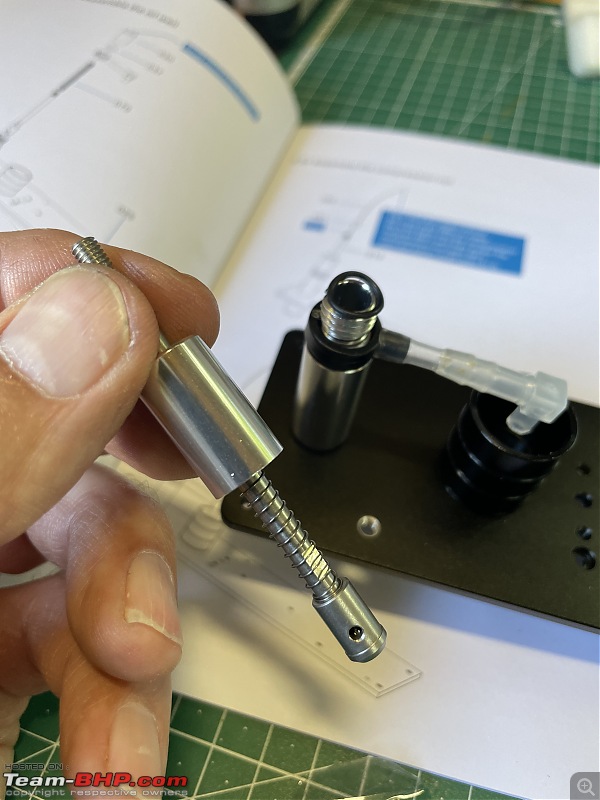

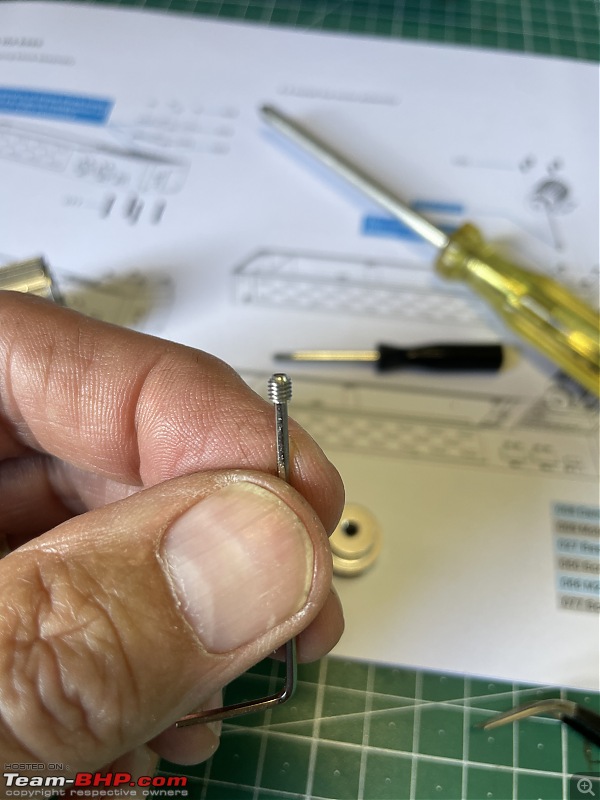

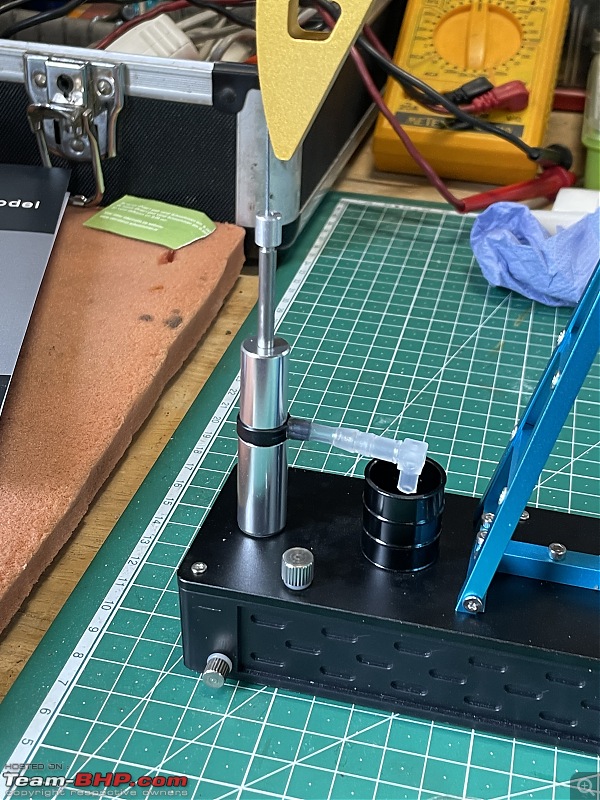

The piston rod comes with its own little check valve. The drill well on this model is only a few centimetres deep, essentially the thickness of the base as you will see. On the real donkey, this bit would be sitting towards the bottom of the well. So the oil is not sucked up to the surface but pushed (or pumped) up from the well. (Sucking won't work as you would not be able to go deeper than approximately 8-9 meters at best.

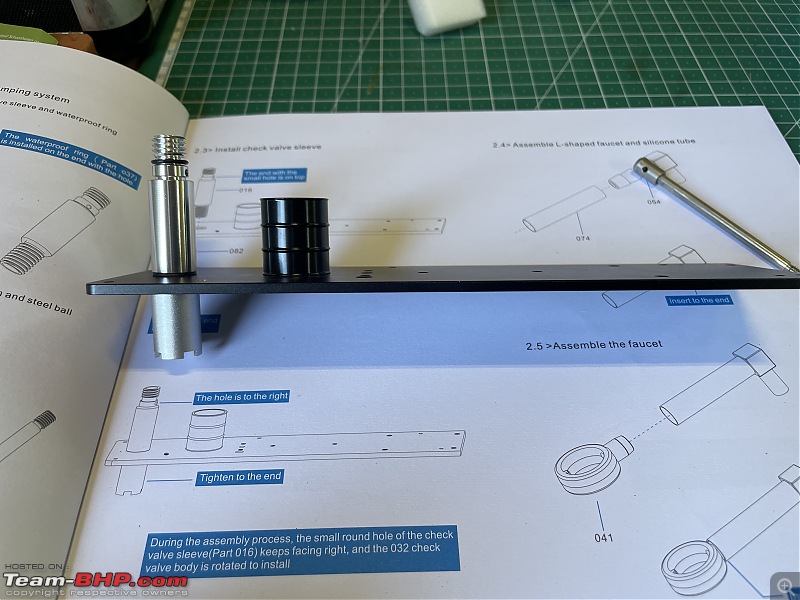

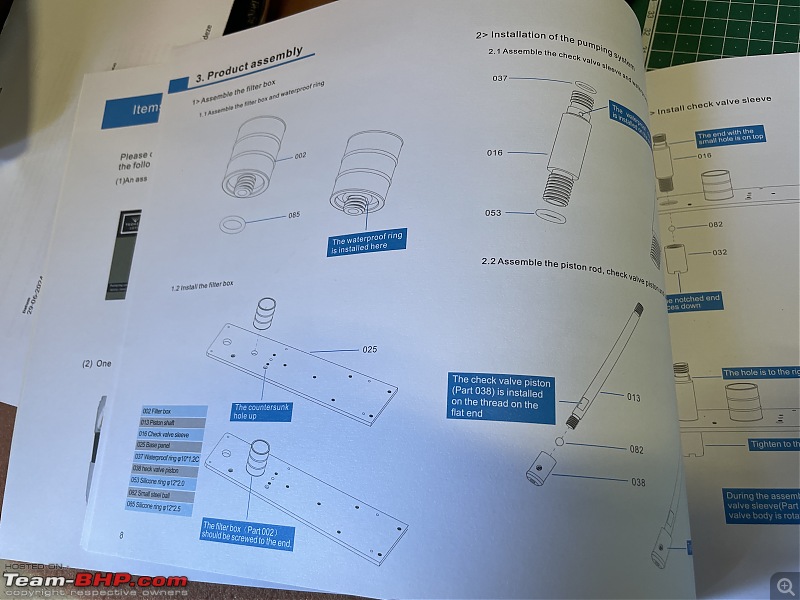

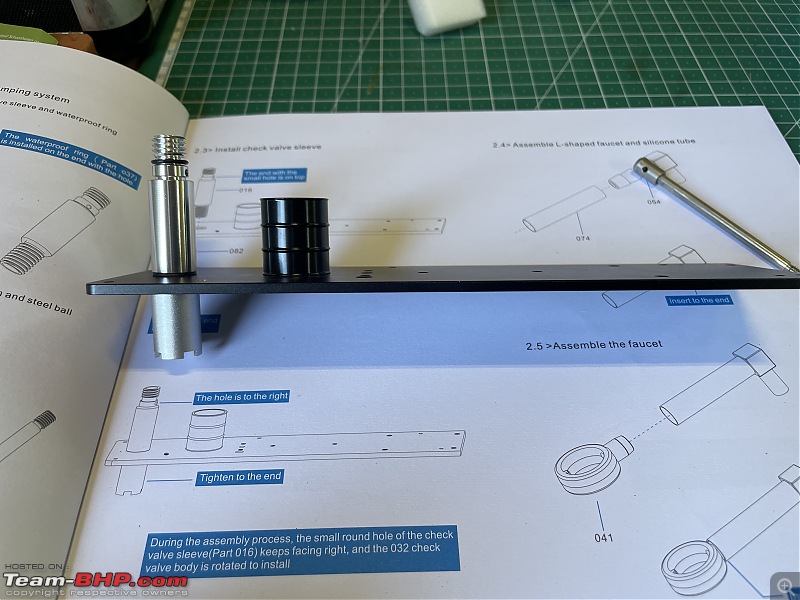

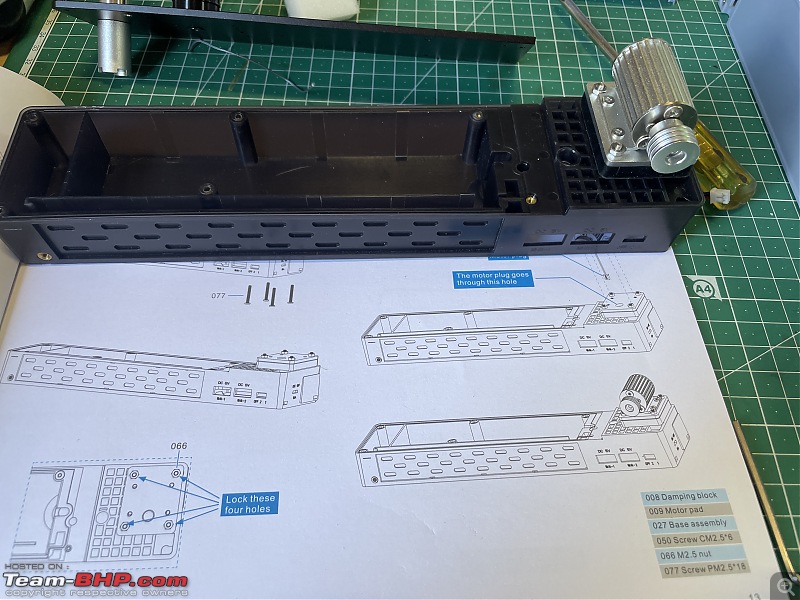

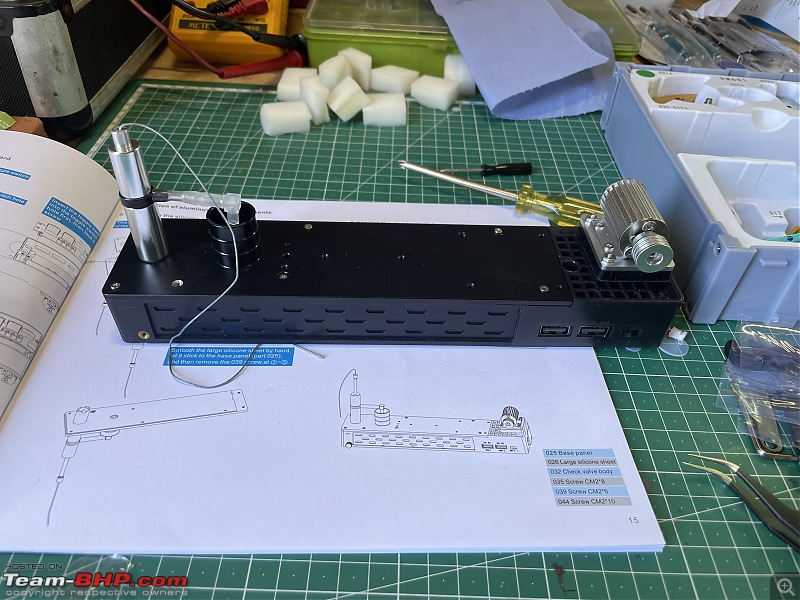

The base plate with the Filter Box and the stuffing box. Inside the stuffing box is another check valve.

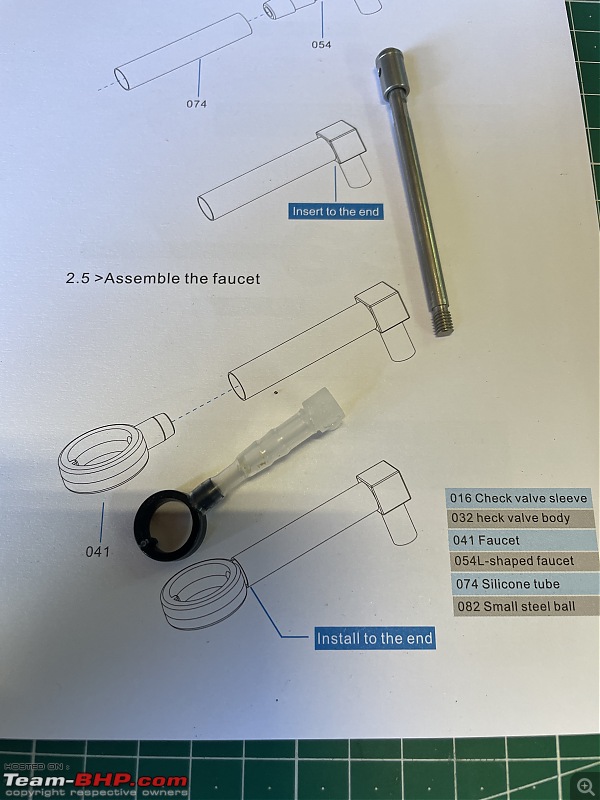

This is a composite part made up of an L-shaped faucet and a small piece of silicone tube. Very tight fit, I put some Vaseline on the faucet to get the tube over it.

They call this cylindrical part over the piston rod the wellbore cover. Notice the spring. Real nodding donkeys don't have springs. The piston will move downwards because of its own weight and gravity. In the model weight and gravity needs a bit of assistance. Hence the spring!

All fitted together

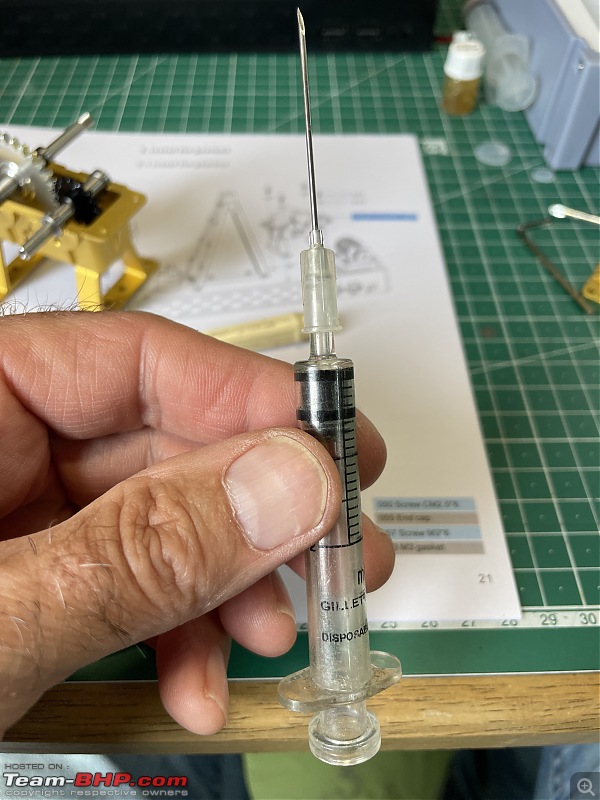

The kit comes with some simple tools. A screwdriver, some small Allen keys and one large open-ended spanner. The other tools I used are some tweezers, a flathead screwdriver and some pliers.

The tweezers are really necessary to pick out the parts from the little box with bolts, nuts and so on. I only took out the parts I needed for each instruction as per the manual.

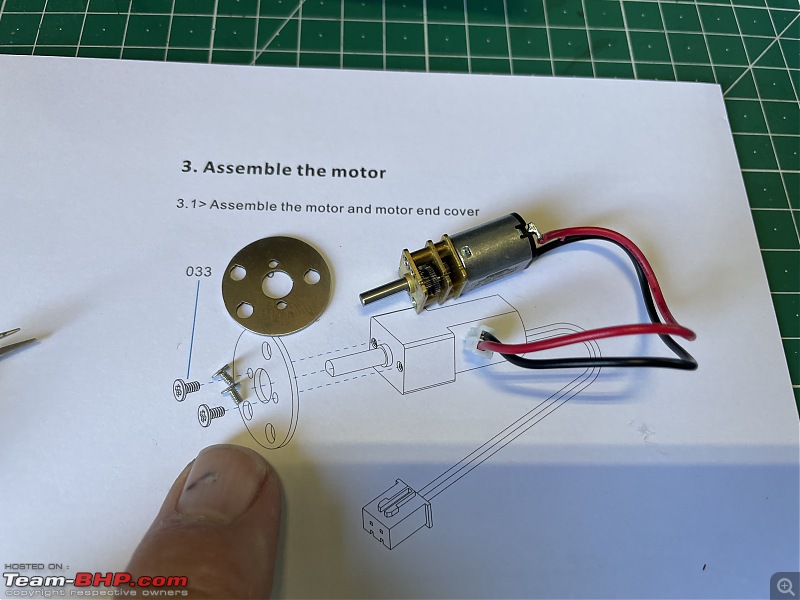

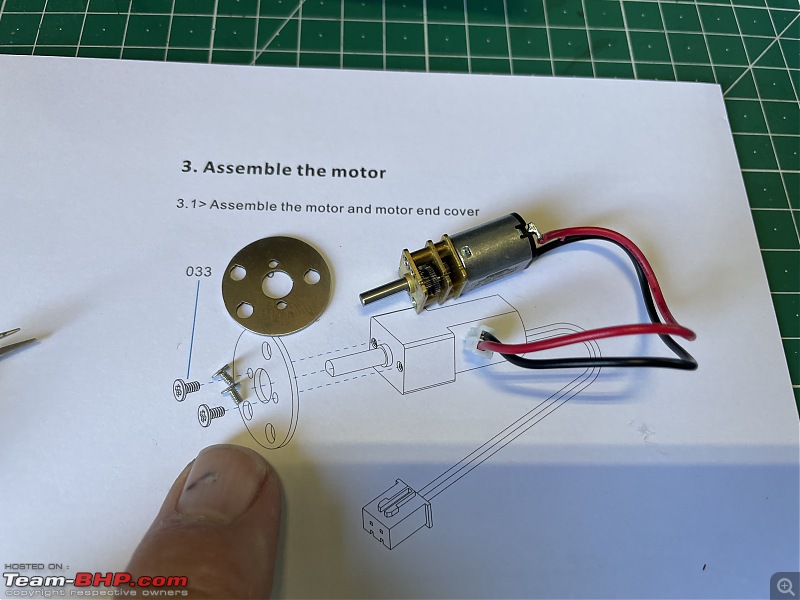

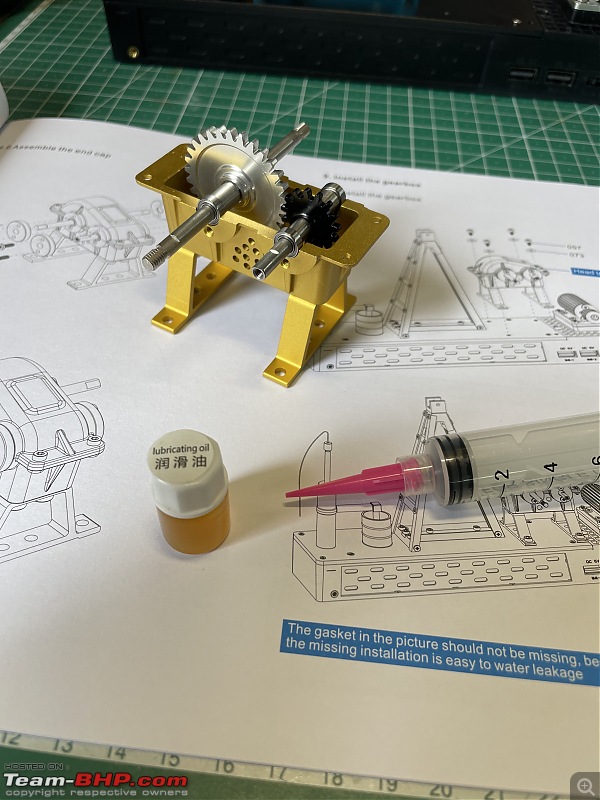

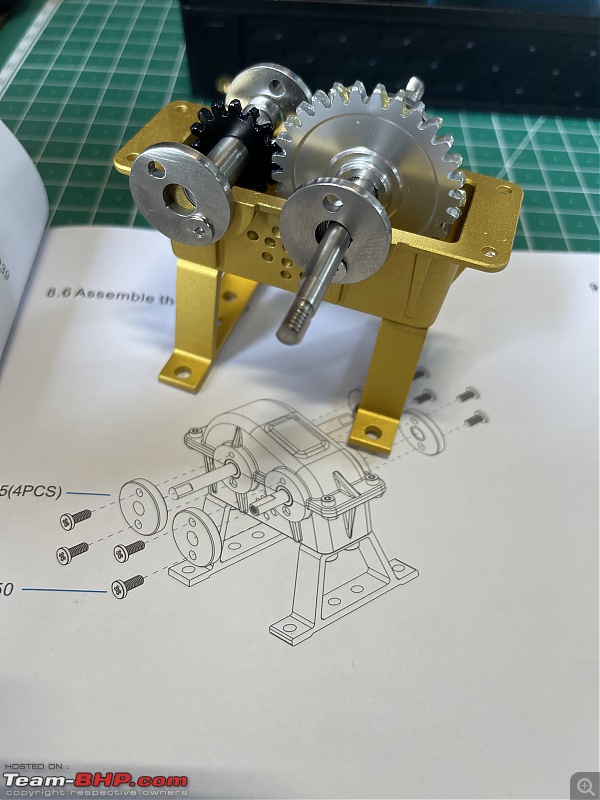

The little electric engine comes together with a small gearbox. You bolt it onto a large flange. (Large being a relative term here, obviously!)

(18)

Thanks

(18)

Thanks

(61)

Thanks

(61)

Thanks

(2)

Thanks

(2)

Thanks

(3)

Thanks

(3)

Thanks

(11)

Thanks

(11)

Thanks

(1)

Thanks

(1)

Thanks

(4)

Thanks

(4)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

These pumping units are known by many slang names at different places. I have wooden non-working model of rod pumping unit as well as land rig which I got from an exhibition in Kuwait.

These pumping units are known by many slang names at different places. I have wooden non-working model of rod pumping unit as well as land rig which I got from an exhibition in Kuwait.