Hello everyone,

After a long time, I managed to take half the day off from work and went to Bumpu's workshop outside Kolkata as I wanted to see the progress that has been made. The body work has not yet started since a 1947 Mercury which requires a lot of tin work is being done, but that should be over within a month and then my car's body work will start. Bumpu is now concentrating on the mechanicals of the car, which he wants to complete first. I wanted the engine to be tackled first, as it was overhauled exactly a year back but not by Bumpu, but my own garage mechanic. So I wanted Bumpu to start her up again and see how she was since she hasn't been started in a while.

Last Wednesday morning I got a frantic call from the workshop, saying that the engine will not budge from the flywheel end by hand.

I was quite horrified! After all, the last time the engine was in action, that too after an overhaul was when I drove the car to the workshop, following which it was taken of the car and stored. Luckily, I then got another call saying that after a lot of trying, this time from the front end, there was a "tick" kind of noise and finally the engine could be turned by hand. What a relief. But Bumpu told me that whoever did the engine, made everything too tight fitting which is why so much effort was required for it to turn. The engine oil was still fresh and more than adequate, so it was mounted onto its actual subrame and secured. Then the radiator was secured on a wooden plank and tied to the subframe, while a rudmentary exhaust pipe (without muffler) was fitted into the exhaust manifold. The carb was cleaned, and she fired up after a few cranks.

However, all was not well, Bumpu told me the engine was running very laboriously and wouldn't idle anywhere near smooth. Then he came across some sort of brainwave, basically he kept adding some 2T oil in the fuel and gradually, the engine started getting better and better. When I went yesterday, the engine had freed up to some extent, and Bumpu demonstrated to me what happens when he added 2T oil; when he added a few drops from the top of the carb, as if by magic the revs would rise and the engine would become absolutely smooth! Bumpu thinks that the engine needs to be run everyday until it eventually frees up, and doesn't think that it needs to be opened as of now. He decided this after the oil pressure gauge showed full pressure for the 2 hours that the engine was on, and only dropped a little when it got to full operating temperature.

Even the water temperature gauge reading was well within limits, except after the first hour when the engine started to sputter and got really hot as a result of which it was switched off but as soon as this happened, large amounts of water was thrown out from the radiator like a volcanic eruption of sorts!

What quite the problem is I'm not sure, but apparently, this only happened yesterday when I was there, not when it was run for the few days before! Anyway, after she cooled a bit, she was re-started and then behaved quite well and I sat close to the engine to try and make out what she was trying to say and realised there was some sort of friction noise. I pointed this out to Bumpu and he investigated by disconnecting the fan belt, after which he spun the fan by hand; the water pump bearing was gone completely and made a very loud noise! The engine was then started without the fan belt driving the fan and now sounded much better. So atleast we now know that the water pump needs an overhaul (this was not done by us), and perhaps the cooling will also improve once that is done. The engine was run again for another hour with Bumpu cautiously adding drops of 2T for added upper engine lubrication. This is now going to be the routine for the engine till it behaves to Bumpu's satisfaction, and if it does not, then we need to redo the engine again. The differential is now in epoxy putty mode and will be painted and closed next week, with all it's new rubber bushes, bellows etc. Then the front and rear suspension work will start for which I need to get front coil springs (one of them was broken when it was taken off!), front kingpin sets and all the wheel cylinders, which are seized very badly.

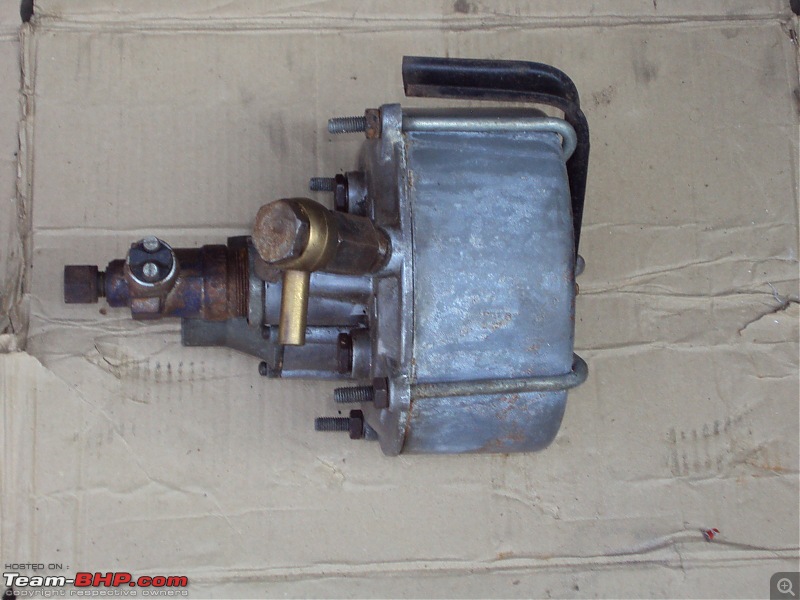

Here are a few pics of the engine on its test bed, differential and some suspension parts.

Also some trim parts (used) which have come in from Australia a couple of weeks back and which will be refurbished later. The headlamps are what I required most, since I didn't have original ones and brand new ones are in the region of USD 600, each! This is way beyond what I'm willing to spend for headlamps so I went with these decent used ones from Australia, though they weren't really reasonably priced. For some reason, complete ponton headlamps fetch astronomical prices on e-bay and elsewhere. Oh, I must mention that the Becker Radio was also tested yesterday and works

.

(1)

Thanks

(1)

Thanks

(3)

Thanks

(3)

Thanks

(2)

Thanks

(2)

Thanks

(3)

Thanks

(3)

Thanks

I was quite horrified! After all, the last time the engine was in action, that too after an overhaul was when I drove the car to the workshop, following which it was taken of the car and stored. Luckily, I then got another call saying that after a lot of trying, this time from the front end, there was a "tick" kind of noise and finally the engine could be turned by hand. What a relief. But Bumpu told me that whoever did the engine, made everything too tight fitting which is why so much effort was required for it to turn. The engine oil was still fresh and more than adequate, so it was mounted onto its actual subrame and secured. Then the radiator was secured on a wooden plank and tied to the subframe, while a rudmentary exhaust pipe (without muffler) was fitted into the exhaust manifold. The carb was cleaned, and she fired up after a few cranks.

I was quite horrified! After all, the last time the engine was in action, that too after an overhaul was when I drove the car to the workshop, following which it was taken of the car and stored. Luckily, I then got another call saying that after a lot of trying, this time from the front end, there was a "tick" kind of noise and finally the engine could be turned by hand. What a relief. But Bumpu told me that whoever did the engine, made everything too tight fitting which is why so much effort was required for it to turn. The engine oil was still fresh and more than adequate, so it was mounted onto its actual subrame and secured. Then the radiator was secured on a wooden plank and tied to the subframe, while a rudmentary exhaust pipe (without muffler) was fitted into the exhaust manifold. The carb was cleaned, and she fired up after a few cranks.