| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  7,787 views |

| | #1 |

| Team-BHP Support  Join Date: Nov 2013 Location: Coimbatore

Posts: 3,711

Thanked: 25,620 Times

| DIY | Upgrading my Prusa i3 Mk3 3D Printer to Mk4 DIY | Upgrading my Prusa i3 Mk3 3D Printer to Mk4I recently upgraded my Prusa i3 3D printer from Mk3 to Mk4. This thread documents this experience. Likes:

Dislikes:

Prelude: The Prusa i3 Mk3For many of my hobbies like electronics, astrophotography etc., I had to make custom parts like enclosures, adapters etc. In 2018, I decided to get a 3D printer for this. At that time, after lots of research, I decided to get the Prusa i3 3D printer. There were many cheaper options available in the market, but I had read that most of these printers are not reliable and one has to spend significant time troubleshooting to keep these printers running. Prusa printers, though expensive, had a reputation for reliability and quality of prints. They had several useful features like automatic bed leveling, filament detection, resume a print from power failure etc. So, went ahead and ordered the Prusa i3 Mk3 printer. The printer came in both assembled and kit forms. As I love DIY, I got the printer in kit form and assembled it myself. The complete kit  Assembling the printer  The assembled printer  The printer served well during the past 6 years. Though I still consider the printer to be under-used, I printed lots of interesting stuff with this printer. A few of them are below. Designed and printed this adapter to connect my camera to the 6" SCT telescope.  Downloaded and printed this adapter to fix my phone to the dovetail base of my equatorial mount to perform polar alignment.  Adapter to fix a webcam to the telescope.  Did some fun stuff too. Designed and printed this sewing thread organizer for my wife.  The printer lived up to its reputation for reliability. In the past 6 years, there were only a couple of problems I had faced.

List of new features:

After checking out several reviews and considering the new features, I bit the bullet and ordered the upgrade kit. The kit arrived from Prague in 5 days. I had to pay a hefty customs duty, but FedEx handled the process smoothly. The package.  The content. I did not unpack all the boxes and take a picture as there were lots of components grouped in the boxes.  Last edited by graaja : 4th April 2024 at 18:07. |

| |  (30)

Thanks (30)

Thanks

|

| The following 30 BHPians Thank graaja for this useful post: | advitiyan, anilsurya1985, chaksjr, dailydriver, dijkstra, Dr.AD, Fuldagap, GTO, InControl, itisravi, KarthikK, keroo1099, kiranknair, MotorDev, motorsan, mugen_pinaki27, NerdyMillennial, Nrulz, Old_Salt, Rehaan, RGK, Samfromindia, sanjayrozario, somspaple, SunnyBoi, suresheadala, Turbanator, udainxs, vignesh207, White Aviator |

| |

| | #2 |

| Team-BHP Support  Join Date: Nov 2013 Location: Coimbatore

Posts: 3,711

Thanked: 25,620 Times

| Part 1: Printing the Plastic Components Part 1: Printing the Plastic Components |

| |  (20)

Thanks (20)

Thanks

|

| The following 20 BHPians Thank graaja for this useful post: | dailydriver, Dr.AD, Fuldagap, gauravanekar, GTO, InControl, itisravi, KarthikK, keroo1099, kiranknair, MotorDev, mugen_pinaki27, NerdyMillennial, Nrulz, Rehaan, Samfromindia, sanjayrozario, SunnyBoi, VaibhaoT, White Aviator |

| | #3 |

| Team-BHP Support  Join Date: Nov 2013 Location: Coimbatore

Posts: 3,711

Thanked: 25,620 Times

| Part 2: Disassembling the Printer Part 2: Disassembling the PrinterOnce the plastic parts were printed, it was time to upgrade. The first step in this process was to disassemble the printer. Only a few parts from the existing printer would be re-used for the upgrade. Everything else will be replaced with new components. Components reused:

Components replaced:

A few pictures from the disassembly. This took about 3 hours to complete. Working on disassembly.  A work-in-progress picture.  The printer completely disassembled.  Last edited by graaja : 4th April 2024 at 17:58. |

| |  (14)

Thanks (14)

Thanks

|

| The following 14 BHPians Thank graaja for this useful post: | anilsurya1985, dailydriver, Dr.AD, Fuldagap, GTO, itisravi, KarthikK, kiranknair, MotorDev, mugen_pinaki27, NerdyMillennial, Nrulz, SunnyBoi, White Aviator |

| | #4 |

| Team-BHP Support  Join Date: Nov 2013 Location: Coimbatore

Posts: 3,711

Thanked: 25,620 Times

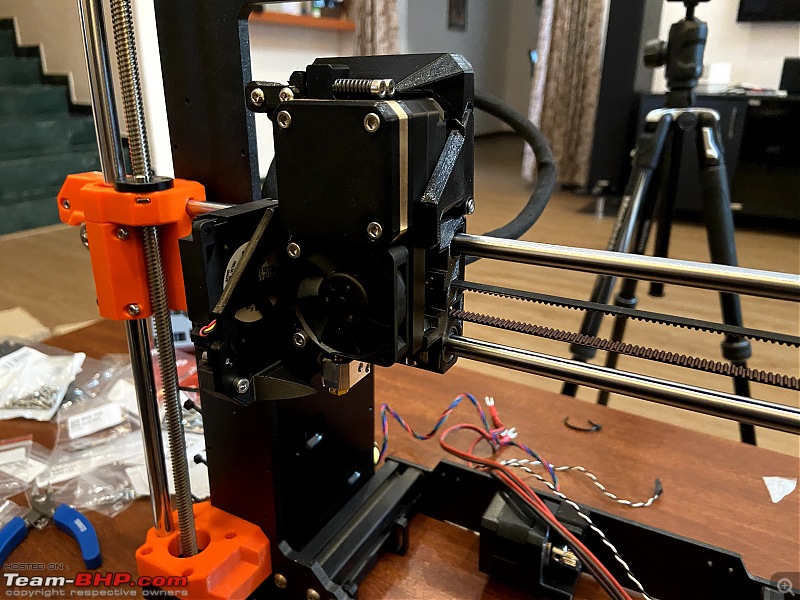

| Part 3: Assembling the Printer Part 3: Assembling the PrinterAssembly took almost 12 hours. Most of this time was spent in reading and understanding all the steps described in the instructions manual, and locating all the parts - plastic components, screws, pins etc. from various packets. I also made some mistakes during the assembly and had to redo the process sometimes. If I were to do this again, I may be able to do this in 6 hours. Following are the various main functional blocks that have to be assembled.

As the assembly was very involving, I missed taking pictures of many functional blocks. Below are some pictures I managed to click during the assembly of some of them. The heated print bed: This is a magnetic bed on which a metal sheet is placed and the parts are printed on this metal sheet. Depending on the material printed, the bed is maintained at a temperature to keep the part sticking to the bed while the print is in progress. This bed can be heated to 100+ degrees Celsius. A thermistor is used to sense the temperature and control the heater. The printer maintains the bed to within 1 degree of set temperature.  The extruder: This is the part that pushes the filament through the heated nozzle. For Mk4, they have developed a new design with planetary gears to push the filament through. The extruder assembly also has a built-in load cell that is used to do the first layer calibration. This is a fascinating design and was a little complex to assemble. The parts needed for the extruder.  Extruder assembly in progress. The planetary gear is assembled.  The fully assembled extruder assembly.  The processor board: This is the brain of the printer and has a 32-bit microcontroller that controls all the operations of the printer. The board is placed inside a metal enclosure and has connectors for connecting various components like motors, sensors, power cables etc. The processor board is installed inside the enclosure.  All cables are plugged into the respective connectors.  The WiFi adapter board plugs into the processor board.  A few work-in-progress pictures. The living room looked like a battlefield for 2 days.    X-Axis Assembly: This assembly carries the print head and moves in the X Axis. The assembly has a base that holds a breakout board with connectors to connect various components of the print head like heater, thermistor, extruder motor, filament sensor, load cell etc. A wiring harness runs from the back of this assembly and connects to the processor board. The extruder assembly is mounted on this carriage. The X-axis carriage assembly with the breakout board.  The wiring harness connects the X-axis carriage to the processor board enclosure. Note how neatly the wires are bunched inside a sleeve. A nylon wire runs along the wires providing necessary mechanical support to the wires.  The extruder is mounted on the X-axis carriage.  Last edited by graaja : 4th April 2024 at 18:35. |

| |  (13)

Thanks (13)

Thanks

|

| The following 13 BHPians Thank graaja for this useful post: | dailydriver, Dr.AD, Fuldagap, GTO, itisravi, KarthikK, kiranknair, MotorDev, mugen_pinaki27, NerdyMillennial, Nrulz, sanjayrozario, White Aviator |

| | #5 |

| Team-BHP Support  Join Date: Nov 2013 Location: Coimbatore

Posts: 3,711

Thanked: 25,620 Times

| Part 4: Powering Up, Calibrations, Test Print, First Impressions, and Conclusion Part 4: Powering Up, Calibrations, Test Print, First Impressions, and ConclusionI started the work on Saturday morning at 9 AM and completed the work on Sunday evening at 7 PM. The total time taken was about 40 hours for printing all the plastic parts and 15 hours for the disassembly and assembly. The final result.   Powering up the first time. The printer performed several diagnostics and calibrations like finding the home positions of X, Y and Z axes, testing the heaters of the print bed and print nozzle, testing the load cell on the extruder, testing all the stepper motors etc. This took about 10 minutes and was a very smooth process.  First test print.   The great satisfaction was that everything worked the first time the printer was turned on. All because of the great attention to detail in putting together the upgrade package and the detailed assembly instructions. Printing the cell phone adapter for polar alignment for a friend.   Having some fun. Printing a Porsche. This model is very small and printed at 200-micron layer thickness. With a 100-micron layer, this should turn out to be smoother.  First Impressions and Conclusion: It has been just about 10 days since the upgrade and I have printed a few parts. Other than the dislikes I had mentioned earlier which were more on the upgrade kit than on the printer itself, my experience has been positive. I love some of the new features. Automatic first-layer calibration: First-layer calibration is where we have to set the distance between the nozzle and the print bed for the first layer to print. Too short a distance the first layer will become too squishy. Too long a distance, the first layer will separate into individual threads. To get the perfect finish on the first layer, in the previous version, I had to perform a manual calibration by printing a test pattern multiple times and adjusting the first layer distance till I got the perfect finish. I never managed to get that perfect finish. But in the new version, the printer automatically does the first layer calibration. The printer moves the nozzle and touches the print sheet and senses the pressure using the load cell and accurately sets the first layer distance between the nozzle and the print bed. With this automatic first-layer calibration, I get a very smooth finish on the first layer. This is by far the best feature I like in this version. Network printing: I can now send the print job directly from my PC to the printer through the home Wifi network. Graphic LCD: Compared to the dot matrix alphanumeric display in the older version, the graphic LCD shows lots of cool information about the print including the picture of the part being printed. I have yet to test the improvement in print speed or the improvement in print quality from the increased resolution of the stepper motors. I will do these tests in the coming days. So far, I am very happy with the upgrade. After a long time, I got a chance to do a complex DIY project. Overall, a very satisfying project, and time and money well spent! That's all folks I have for now. Thank you for reading! Last edited by graaja : 4th April 2024 at 17:54. |

| |  (44)

Thanks (44)

Thanks

|

| The following 44 BHPians Thank graaja for this useful post: | advitiyan, anilsurya1985, asbshyam, BlackRaven, BulZire, chaksjr, dailydriver, DAYDREAMER, Djay, Dr.AD, Fuldagap, gauravanekar, GTO, InControl, itisravi, JayKis, KarthikK, kiranknair, Livnletcarsliv, Motard_Blr, MotorDev, Mr.Bentley, MrMcqueen, mugen_pinaki27, NerdyMillennial, Nrulz, Old_Salt, pram_ind, Rehaan, RohanMahantesh, safe_rider, sainyamk95, Samfromindia, sanjayrozario, somspaple, SS4, Stranger2106, SunnyBoi, Torino, VaibhaoT, Venky03, vignesh207, White Aviator, Zen_forever |

| | #6 |

| BHPian Join Date: Nov 2010 Location: BLR[KA]/DPM[TN]

Posts: 412

Thanked: 260 Times

| Re: DIY | Upgrading my Prusa i3 Mk3 3D Printer to Mk4 Raaja Sir, this is super interesting!. Thanks for sharing  . . you are seriously a character to get inspired from. Technology, Fitness, Cars, Stars and what not that we don't know about you yet ?  |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank BulZire for this useful post: | graaja, GTO |

| | #7 |

| Distinguished - BHPian  Join Date: May 2010 Location: Bengaluru

Posts: 4,453

Thanked: 6,794 Times

| Re: DIY | Upgrading my Prusa i3 Mk3 3D Printer to Mk4 graaja, this is a pro level DIY! I like the meticulousness and the attention to detail that you give to your work! I noticed perfect crimps on the insulated terminals. Can you share what crimper you use? |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks sagarpadaki for this useful post: | graaja |

| | #8 | ||

| Team-BHP Support  Join Date: Nov 2013 Location: Coimbatore

Posts: 3,711

Thanked: 25,620 Times

| Re: DIY | Upgrading my Prusa i3 Mk3 3D Printer to Mk4 Quote:

Quote:

For this DIY, I did not have to crimp the terminals. The wiring harnesses with proper crimped terminals were part of the upgrade package. For my other projects where I do my own wiring harnesses, I use the below crimping tool.   | ||

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank graaja for this useful post: | BulZire, dailydriver, NerdyMillennial |

| | #9 | |

| Distinguished - BHPian  Join Date: May 2010 Location: Bengaluru

Posts: 4,453

Thanked: 6,794 Times

| Re: DIY | Upgrading my Prusa i3 Mk3 3D Printer to Mk4 Quote:

Wanted to get a proper one for crimping insulated and non insulated terminals and thought you had done the crimping from the pics. | |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank sagarpadaki for this useful post: | graaja, mugen_pinaki27 |

|