Some of you might have been following my thread on fiddling with my cars.

https://www.team-bhp.com/forum/diy-d...eo-spider.html

I have been maintaining and adding to this thread for the better part of four years along the lines what I consider “fiddling” with cars. Which for me is a very broad definition. Anything I do with my cars, from fixing them, visiting car shows or technical club meetings, touring around the Netherlands/Europe gets shown. Along the way it also shows how my garage/workshop has got better equipped with more and more tools over the years.

Earlier this year I got myself a little Lathe for my birthday: (Well, technically it was a present from my wife)

I have some experience from my merchant navy years in metal working. But it has been well over 30 years since I worked on a lathe. So a lot of catching up to do.

The Internet is full of all kinds of tutorials. I found Blondihacks channel extremely useful, well made and full of valuable detailled information, suggestions and tips.

https://www.youtube.com/channel/UC7J...4e74O53dL6arSw

(She has just started a new project, building a steam engine using a kit with casted parts)

I found the best and most enjoyable way of learning is to find a little project and produce something tangible. I made the odd tool, but I needed something a bit better; To this effect I decided to build a little Oscillating Steam Engine. Also, known as a Wobbler engine.

I found it on the internet. Detailled plans and a step by step description:

http://www.steves-workshop.co.uk/ste...impleoscil.htm

I finished the Wobbler a few weeks ago and made this little video:

My little Wobbler also made it to Steve’s Gallery:

http://www.steves-workshop.co.uk/ste...ersengines.htm (scroll all the way to the bottom)

It is fair to say, building this little engine gave me enormous satisfaction and I learned a lot. Many thanks to Thad, Sutripta and other members for their continuous encouragement and advise along the way

After completing the Wobbler, I decided I have a taste for more. I really enjoyed building up my metal working skills once again. So I have chosen a second project. I also decided to give it its own dedicated thread, which I hope will work for everybody.

It took me some time to choose my next project. It had to be a little more complex than the Wobbler. It should still be possible to produce it on my little lathe and mini mill. Also, I have very strict requirements on the technical drawings. I have some cognitive problems these days, which also means that reading technical drawings is becoming a bit of a challenge now and then.

So I need preferably 1:1 drawings, everything needs to be in metric (having to work conversion is just to confusing). I must admit I do like steam engines and there are a lot of them about.

In the end I decided on something a bit different. I have also joint a few (Dutch) model building forums and I became a member of the Dutch Model Building Association.

I got a lot of information and tips on these forums too. One of the guru’s in the Dutch model engine building world is Jan Ridders. Have a look at all these different models he designed and build himself!

http://ridders.nu/index.htm

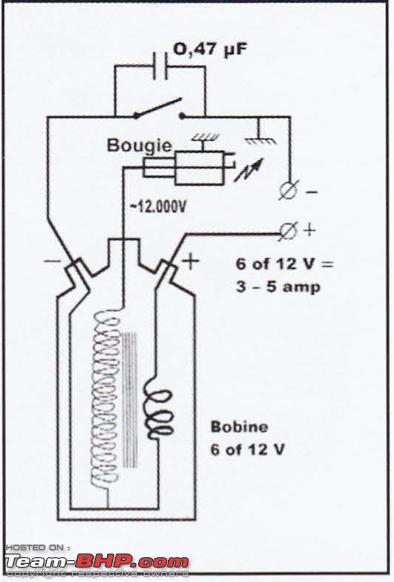

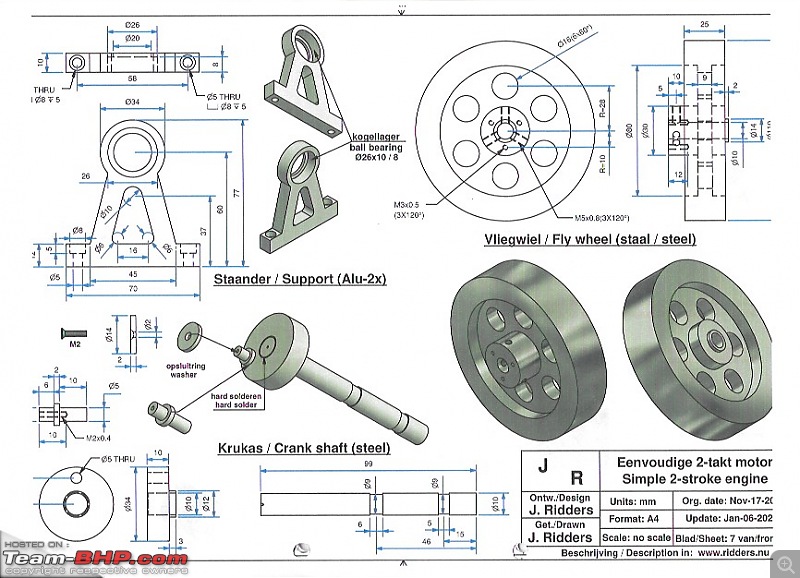

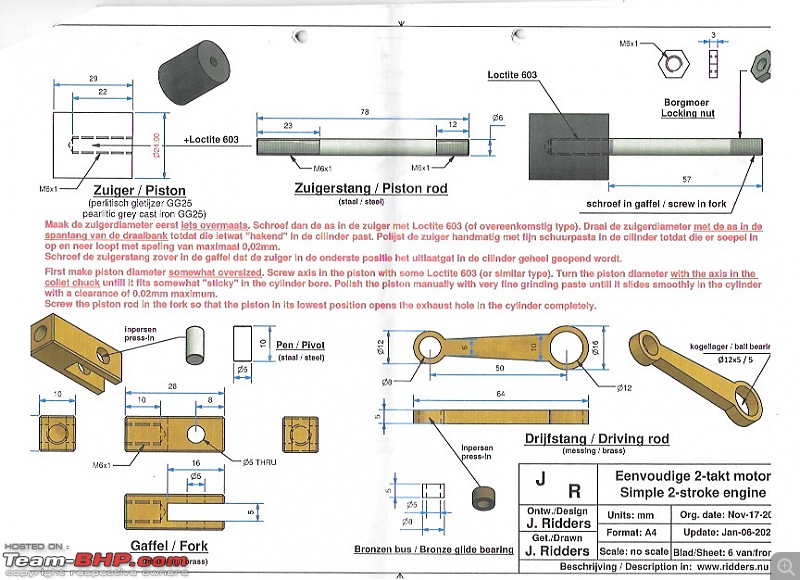

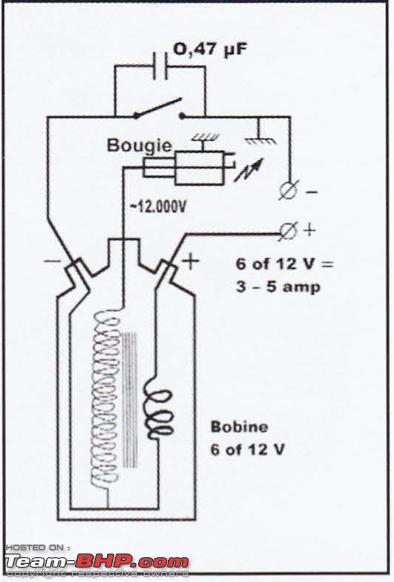

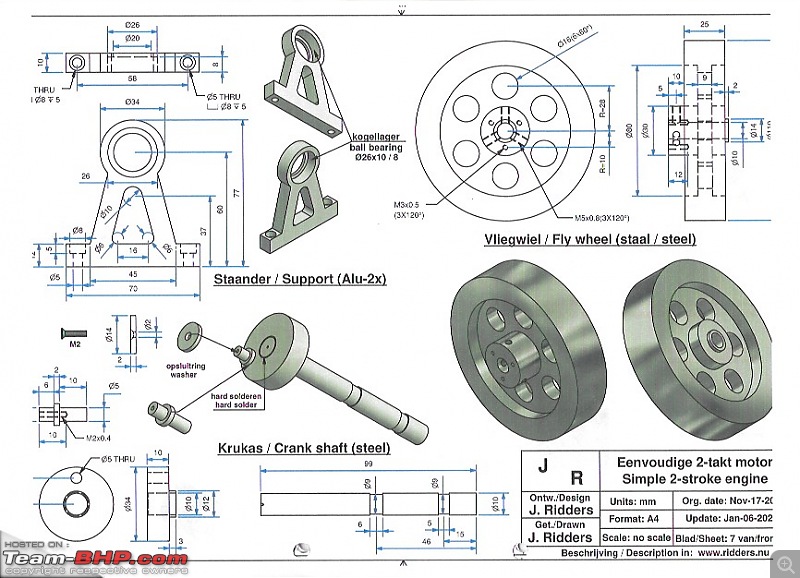

In the end I decided to go for one of his models; Debbie a small, simple two stroke engine!

The original design is from 2006. Jan did a very nice article in the NVM club magazine (Dutch model build association). I managed to get hold of that original article. Since he has amended the design a bit, noticeably the cylinder and the support.

At present I am busy trying to figure out what materials I need to get. I have some stock myself, but I need quite a few more bits and pieces. So I have made a very simple Excel sheet. I went through the drawings one by one and wrote down the details of every single part. Checked whether I have the respective materials in stock, checking dimension, if not what to order.

Debbie Two Stroke.xlsx

I am also trying to figure out on how to go about producing the different parts. This one has at least two major challenges compared to the Wobbler. The piston and cylinder have very narrow margins, I need to machine them very precisely. Also, the cylinder is 24mm in diameter, which means I need to bore, which is something I have not done yet! I probably need to get some boring bars as well.

Also, the frame or support in which the flywheel will rotate is going to need some thinking on how to approach. I think I can manage to outside shape ok-ish. But the trick is that the inside that holds the bearing, need to be pretty precise and of course perfectly aligned between the two support as well.

More to come!

Jeroen

(39)

Thanks

(39)

Thanks

(1)

Thanks

(1)

Thanks

(6)

Thanks

(6)

Thanks

(1)

Thanks

(1)

Thanks

(5)

Thanks

(5)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(6)

Thanks

(6)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(6)

Thanks

(6)

Thanks