Still waiting for the builder to show up and fix the last bit of the driveway. And the plumber to finish the plumbing part of our project.

Still, last night I made very good project on my Spider emergency bonnet release

I decided wanted to have the emergency release close to the original release. I wanted to be able to pull it without having to take things apart. The solution I found on the USA Spider website, would probably mean taking a wheel off!

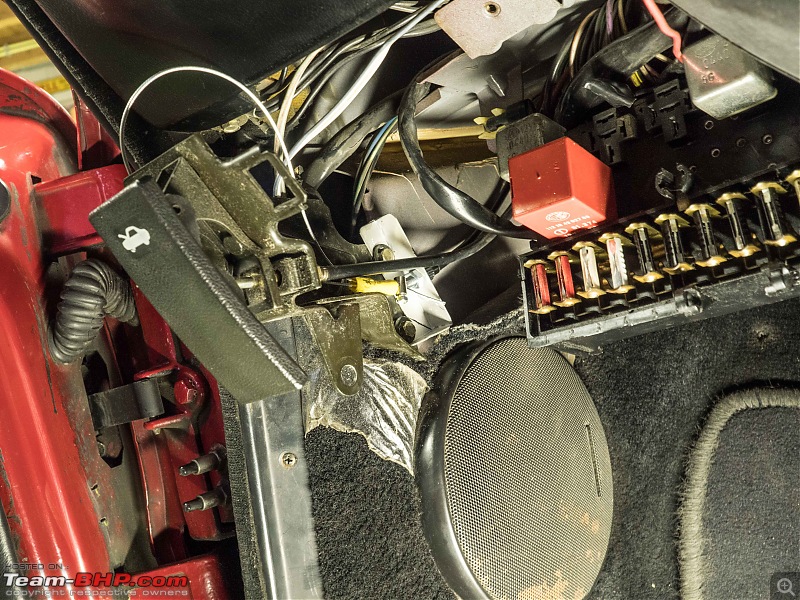

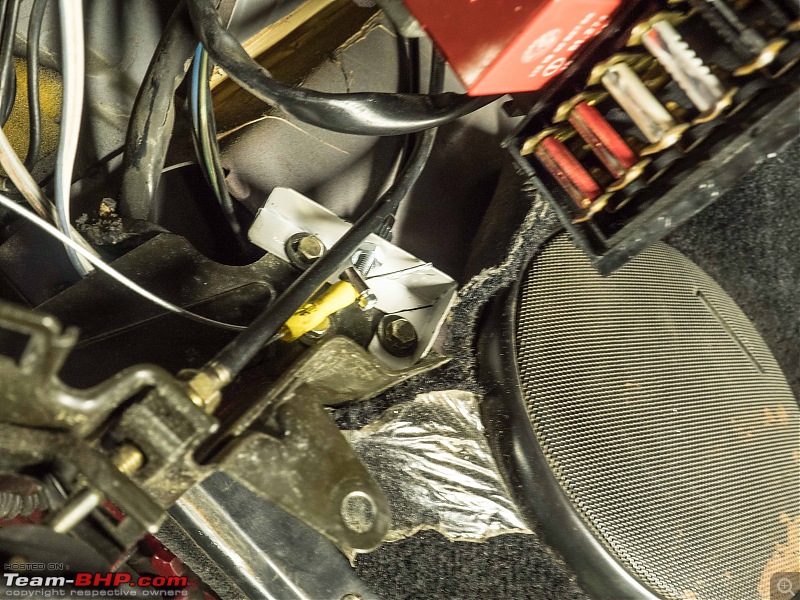

But in order for the emergency release to get close to the original release lever, the cable needed to routed alongside the original one. Here is the original one, the black tube with the open cable tag attached. It goes through a rubber grommet into the back of the dashboard.

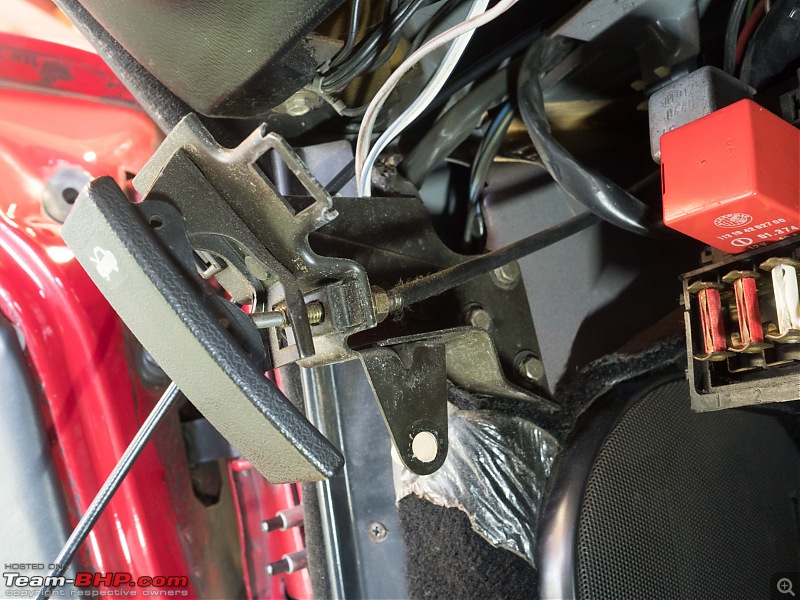

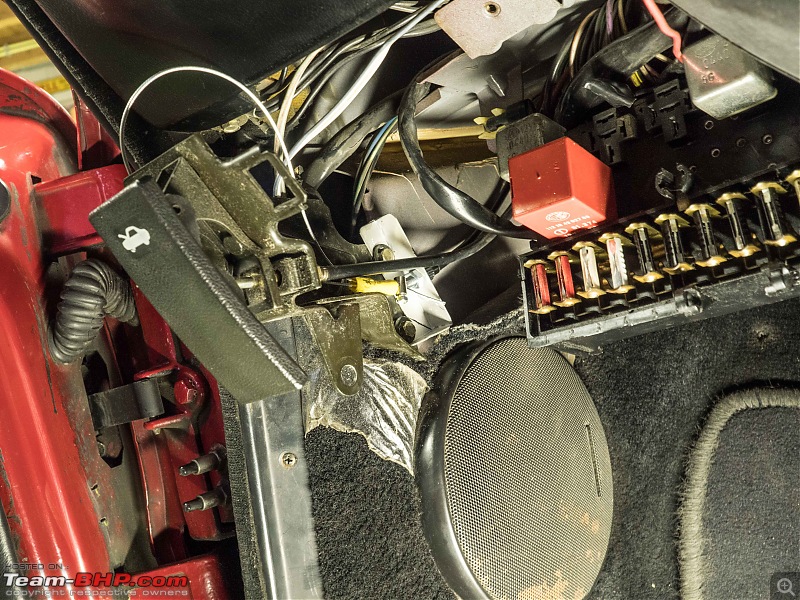

I have removed part of the kneeboard here, normally this part swivels on two little hinges and provides easy access to the fuses. But with it removed you can see the original release lever

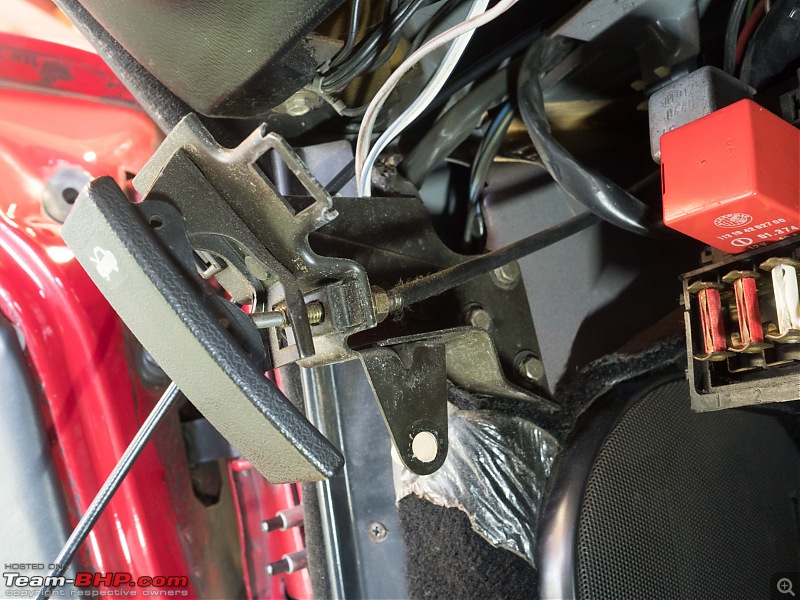

I thought it would be a good idea to somehow have the emergency release behind the bracket of the original release lever. There was some room and some bolts to attach an additional bracket too.

Need to poke a hole in the grommet to push the new outer cable through. I tried this first

To no avail. This grommet was old, but very very tough. So more elaborate tooling was required. Got my pneumatic drill out, that fitted exactly in between all the other parts!

Here you see the new outer cable pushed through the same grommet as the original (outer) cable.

I just kept feeding the new cable through. I was expecting it to get stuck somewhere underneath the dashboard. I was pleasantly surprised when it just popped out from underneath the dashboard, all by itself!

However, it somehow found its way along a very different path and it wasn’t anywhere near the back of the release lever. I spend about 45 minutes to try and get it there. Head in the footwell, underneath the dash. Very uncomfortable.

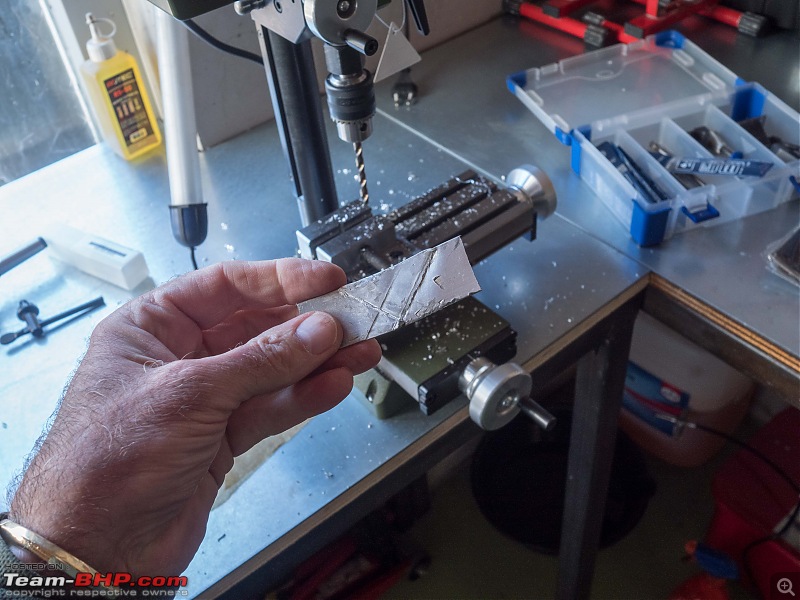

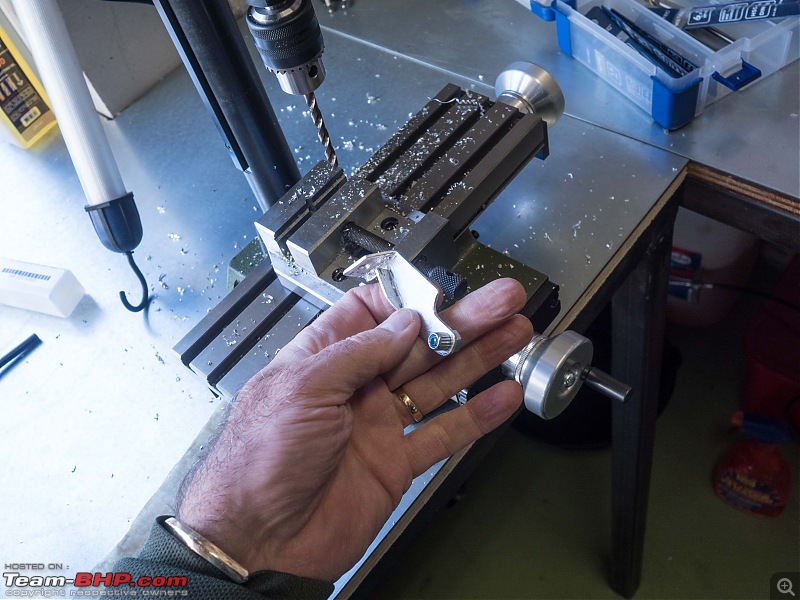

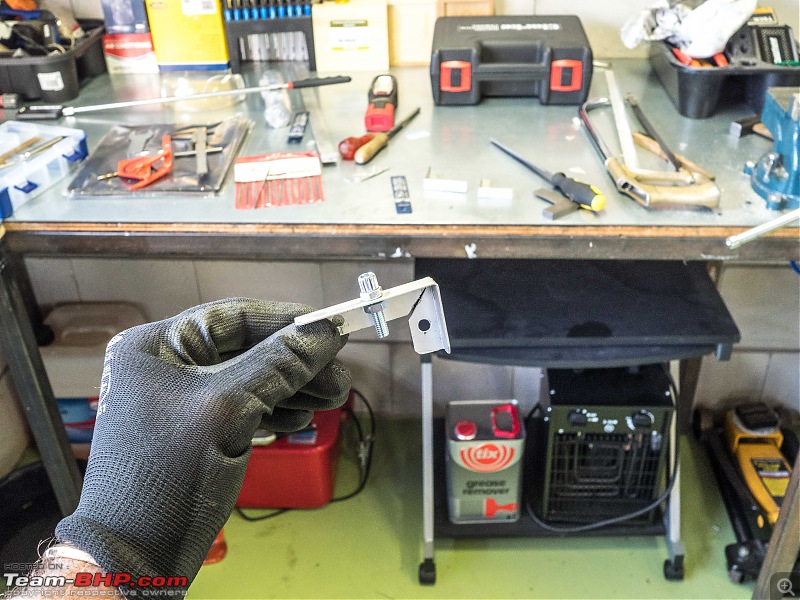

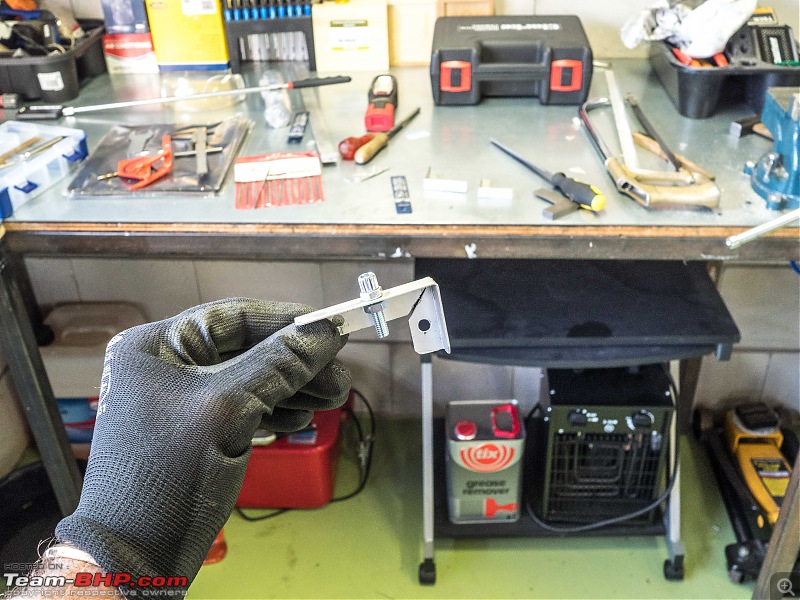

I could not get it properly routed. So I came up with a cunning plan. From a piece of simple metal wire I made this little “follower clamp”. Now when I push the new outer cable in, it will follow exactly the route of the old outer cable.

Worked a treat!

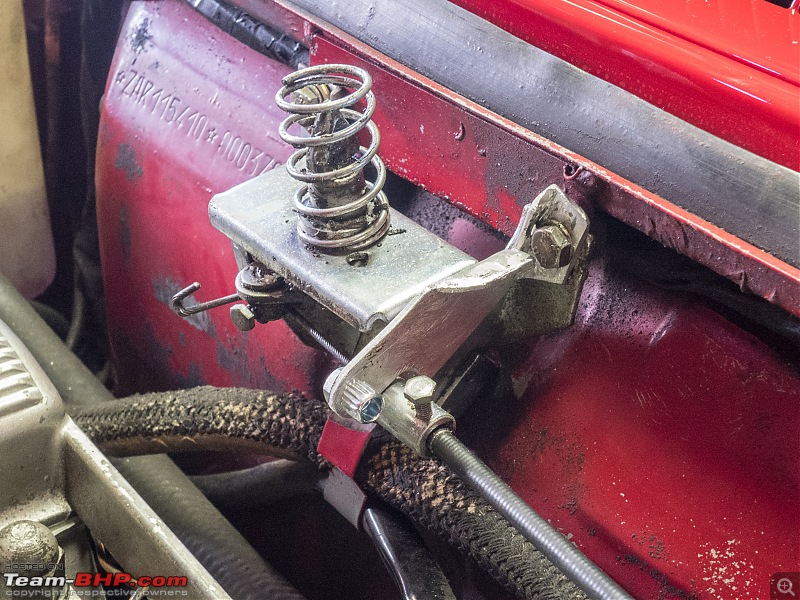

Next another bracket to be mounted behind the normal release lever:

Then I inserted the inner cable, always a bit fiddly and I put some simple bearing grease on it too.

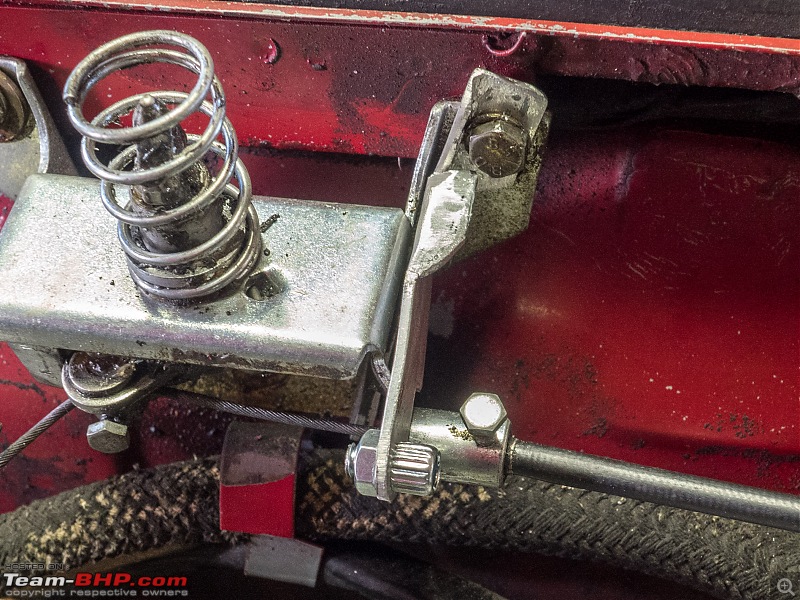

A few more bicycle bits came in handy to attach it to the bonnet release mechanism.

This is how things look under the bonnet:

And this is how things look under the dashboard, near the original bonnet release lever:

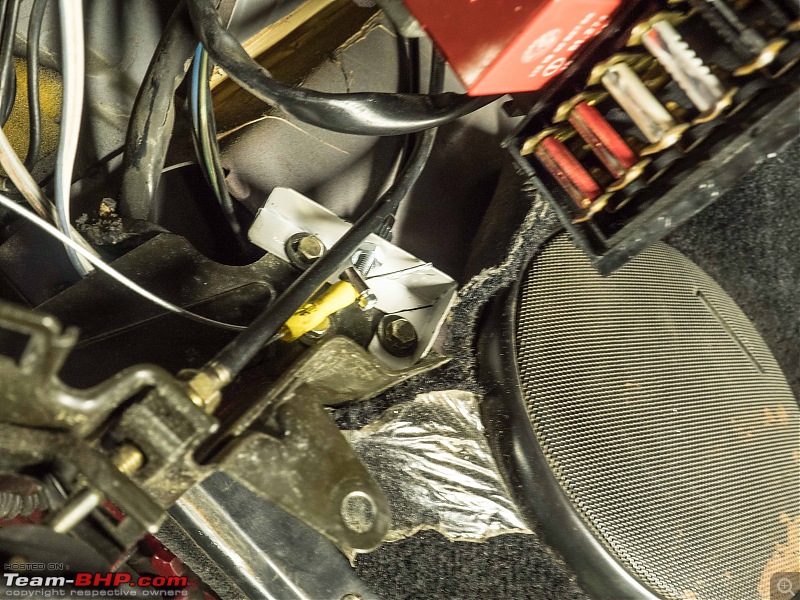

I just looped the inner wire and clamped it with an electrical wire connector and another bicycle bit. I tested it about a dozens times and it works really well.

As usual, lots of tools everywhere. If you look closely you will also notice two fuses on the floor mat. When I was fiddling with the inner cable, trying to loop it, clamping it, it brushes across the fuse box and shortened two fuses! Did I mention you should always disconnect your battery!! No matter what!

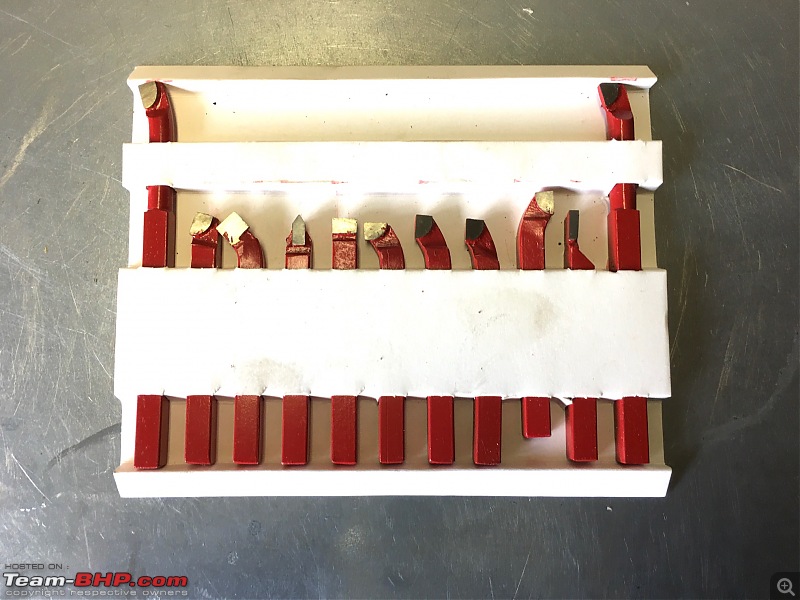

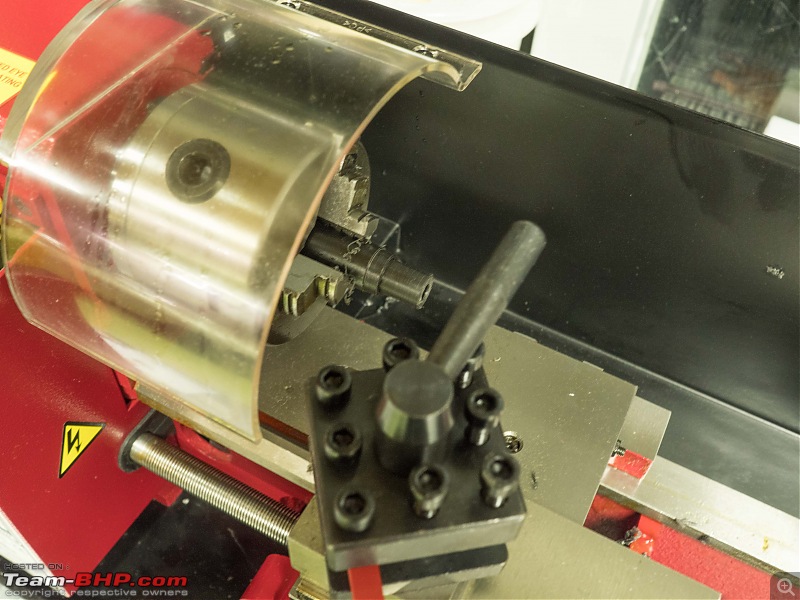

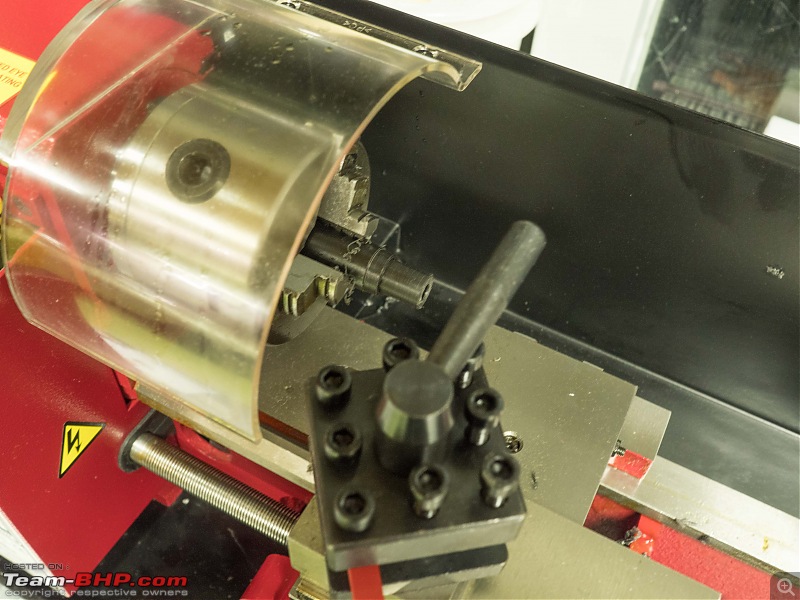

I have also started with my very first little project on my lathe. The hinges of the knee pad protector swivel in a nylon bushing. One is completely perished. I tried to repair it earlier, it is somewhere in this thread. But it came apart, so I am making a new one! The hinge pins on which it swivels are 7,3 mm. Regular sets of drill rarely have a 7 mm drill bit, let alone a 7,3mm. So I found a website where you can order drill bits, per piece in any diameter, 1 mm increments. Obviously, I have opened an account with them!

Also, last Sunday when I took the Spider for a blast, I had to move the Jaguar out of the way. I noticed a little bit of oil on my garage floor! I don’t think I have ever seen any oil leaking from my Jaguar before. Apart from the hydraulic hose that was damaged and I replaced several years ago.

So most likely another Jaguar project coming up.

I have mentioned before; I used to be very active in the Dutch Alfa Romeo Spider Register. Usually together with spanner mate Peter. We havent done much for our club over the last years. That is fine, we did our thing for 10-15 years, time for others to take over. Due to the Corona, obviously, our events have been cancelled.

Peter and I have come up with “virtual technical meetings” for our members. We will be discussing various repair and maintenance jobs. Tonight the first prep meeting with some folks to organise it all. Look forward to it!

Jeroen

(1)

Thanks

(1)

Thanks

(4)

Thanks

(4)

Thanks

(1)

Thanks

(1)

Thanks

(4)

Thanks

(4)

Thanks

(3)

Thanks

(3)

Thanks

(2)

Thanks

(2)

Thanks

(6)

Thanks

(6)

Thanks

(4)

Thanks

(4)

Thanks

(4)

Thanks

(4)

Thanks