| |||||||

|

| Search this Thread |  1,042,635 views |

| | #481 | |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

Only after they inspect the car in detail, discuss your requirements, look at it some more, think about and then they will quote you a unique price. What they do is always specific to the job and the owner requirements at hand. They don’t quote prices, so neither will I publish what I pay them. Because if you really understand what it is they do, and I hope to have showed that in the various detailled posts, it must be obvious that it is way beyond your typical standard job. Whether it is Matthieu doing my Spider, or Joost the leather seats of my Jaguar. So comparing these sort of prices, is akin to comparing apples and oranges. But think of it like this; Matthieu spend about two hours inspecting and discussing with me about my requirements, giving advice and then we agreed on a scope, methods and price. It took him more than 20 hours and in total he has driven up and down three times as well. 45 minutes one way. He has an extremely well equipped mobile workshop and Swissvax materials are not known for being cheap. He runs his own business and he has been doing this for some twenty years. If you would like him to come around and do your car, he won’t have time until 4-5 months from now! Given all of that I was actually pleasantly surprised on what he charged. And I told him so, I honestly think he is underselling himself. I really don’t mind paying them well. I always tell them if the job, for whatever the reason, turns out more difficult or requires more time than originally thought, let's discuss and adjust. I genuinely like these guys. We get on really well, and whenever I have some questions, they are more than happy to pop around, give advice etc. That is important to me. Polishing and wax jobs do get advertised by other parties. They will charge Euro 250-450, they advertise in the various classic car magazines with prices like that. But it will not even come close to what Matthieu does. Moving on: I just go some images Peter took last Friday. He came around for the appraisal of my three cars. But he also brought the frame of a wheelbarrow that needed a bit of welding. Happy to help out of course,    As I mentioned before, on 1st of March both my Spider and W123 are allowed back onto the road. And of course, I did take them out for a short spin. The Mercedes W123 did fine, the sticking brakes were gone, within 10-15 meters of driving. The Spider drove well. But the braking problem is still there. It is a bit odd. When I drive it on a straight stretch of road, take my hands of the steering wheel and brake, the steering wheel turns to the left somewhat, but the car brakes straight ahead. When you keep your hands on the wheel, it obviously pulls right unless you turn slightly left. I am not sure this is to do with the brakes at all. More like something in the suspension, maybe some bushing worn. More to investigate. I also do have a problem it appears with the cooling liquid. The expansion tank is almost empty, but I have not been able to find where it leaks! So I will probably plan another trip to Goof to put it onto his lift and see what’s what. Despite those little niggles, it looks absolutely stunning:  Jeroen Last edited by Jeroen : 1st March 2020 at 16:54. | |

| |  (7)

Thanks (7)

Thanks

|

| The following 7 BHPians Thank Jeroen for this useful post: | ashis89, digitalnirvana, Karthik Chandra, Nempuguru, Thad E Ginathom, vaasu, VivekCherian |

| |

| | #482 |

| Distinguished - BHPian  Join Date: May 2010 Location: Bengaluru

Posts: 4,359

Thanked: 6,468 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp A probable cause would be the stabilizer link rod.I am not sure if the spider has them. Worn out link rod ends also cause such behavior |

| |  ()

Thanks ()

Thanks

|

| | #483 | |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

Jeren | |

| |  ()

Thanks ()

Thanks

|

| | #484 |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp At long last, we had a few hours of sun shine. So I took the Spider for another little test run. So far the cooling liquid (which I had replenished) is staying at the same level. I have not been able to detect any cooling liquid dripping anywhere. So still not sure, where these little puddles I discovered some time ago, came from. But anyway, so far so good. I have discovered a few other little problems that need fixing. The locking mechanism of the driverís door is too stiff, meaning it does not move back in its default position, unless you actually move the handle back. Probably needs some grease. For some reason there seems to be a bit of condensation in the dashboard. Never had that before. It was very cold, but with sunshine, so maybe some odd temperature differences that caused this phenomena. Getting the front of is easy enough. But it is a plastic bezel and they do become brittle over time, and I do not want to break it. So lets hope it disappears by itself, so I donít need to take it apart. The (de-misting) fan is not working. It has two speeds, which is indicated with a yellow caution light on the dash board. That does work, but the fan does not run. So I need to check. It could be a case where I just need to give the fan a little push. It has been sitting idle for over three months. Sometimes they seize a bit. If I need to remove it, it is going to be a big job! But lets see. It is actually required to have a working de-misting fan for itís MOT! I am not quite sure if the AC is working properly. The fan is definitely blowing, but I am not sure if the clutch is engaging. Usually I should be able to hear it engaging, when I switch it on and the Volt Meter in the Dash drops a bit. None of that. But it could be that it was just to cold. Usually ACís donít work below 4oC. So some progress and some more fiddling to do. I already spoke to Goof and I will take the Spider to him, so we can put it on the lift to have a good inspection of the brakes and suspension. I am also becoming slightly suspicious of the rear end. This car has trailing arms and a central connection on the diff. All rubbers and they perish over the years. I have replaced all this lot some 20 years ago, so it would not come as a huge surprise if something needs replacing again. The test is to get onto the motorway, flat straight stretch. Get into 3rd of 4th gear, floor the accelerator and release. If the car does not keep going straight, very likely there is something with the rear suspension/trailing arms or this so called Diablo Rubber which helps connect the diff to the chassis in the middle. Jeroen |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank Jeroen for this useful post: | digitalnirvana, Thad E Ginathom |

| | #485 |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,259

Thanked: 28,606 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp |

| |  ()

Thanks ()

Thanks

|

| | #486 |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp

It should not be too scary. You will only need small steering corrections, if the rubbers are somewhat perished. If they are in really bad shape, it will be easy to actually see upon inspection, or you might even get metal to metal type of sounds when accelerating and it is likely to be noticeable under more or less normal driving conditions. This little test is a well known to most Alfisti, as quite a few their earlier cars had similar set ups. Bear in mind, we are used to modern cars. Even at the best of times, these old classic cars tend to be a little less tight than any modern car. So they move about a bit, when you accelerate, when you drive etc. Part of the charm as they say! Jeroen |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank Jeroen for this useful post: | digitalnirvana, Thad E Ginathom |

| | #487 | |

| BHPian | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

| |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank KkVaidya for this useful post: | Jeroen, Thad E Ginathom |

| | #488 | |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

Usually I absolutely hate endless repeating never ending jobs. E.g. doing the laundry, washing up, hoovering, dusting, cleaning the windows, mowing the grass etc. However, when it comes to fiddling with my cars, is somehow never really bothers me! Had a very interesting afternoon. As you might recall, my friend Berndt and I, jointly bought the Souriau tester. After weeks of searching and research I had finally found somebody who knew these kind of instruments. He told me to come over and bring it, so he could check it out. So around 1300 pm Berndt rocked up in his Rover 75 estate. He has some 12 cars, and even two Rover 75s. This one being a bit of his workhorse, for moving stuff around.  I had already got our tester out of the garage. Ready to load!  The place we went was about a 50 minute drive from our home, mostly motorway. A village both Berndt and I knew well, as it was very close to Amsterdam, where both of us were born and grew up. When we arrived, Leo the owner and founder of TBA (https://ten-automotive.com) came outside to welcome us. He showed is into his office, where we talked for a long time. Leo told the company history. It was quite an amazing story. This is his own company, build from the ground up. These days it is the market leader in various automotive emission analyser. They do their own research/development/production. Leo, or rather his company, was the official importer and distributor of the Souriau Brand!! He used to sell these instruments, he used to teach mechanics on how to use it and he used to service them! Soon we found out he himself is quite the classic car collector himself. He has quite the eclectic collection. Early Renault 4, Jaguar XJR, Triumph 3, 4a, 6, Morgan etc etc. We also found out that friends of Berndt are actually Leoís neighbour!! That guy, obviously, has a classic car too, another Triumph 4! It is a small world!! Anyway, after lots of interesting discussion Leo showed us into one of his garages. He has kept a number of the various Souriau analyser and tester, in what he calls his little museum.    A view to some of his cars:  Leo showed us how to hook up the tester to one of his own classic cars.  He showed me all the various settings and working of each measurement. Almost everything works. He did not have a replacement for the missing part. He did have one we tried, but it would not work. He suspected it was not so much the probe, but some internal problem. All in all, very happy with this. Nearly all the functions on our meter work, except the high voltage one. I know how I can make the missing part myself. Leo showed me. Leo offered to have one of his technician check the high voltage circuits. Also, Leo still has the original calibration unit at home. So we left our meter with him and see what else he can do with it. Afterwards he showed us around his company. And some more cars too. His son, who actually runs the company now is very much into (young timer / classic car racing) Look at this:  The truck at the back is used to transport the cars to the track and also functions as a mobile workshop and mobile home. The car being assembled is quite an unique one. It is the F3 in which, many years ago, Senna became F3 world champignon. Leo and his son are restoring it back to its old glory. It has an Alfa Romeo Engine apparently.  Leo also showed us around the production and assembly facilities. Most of these instrument find their ways to various workshop around the Netherlands and abroad. Leo has about 40% of the market captured. Most of it are MOT stations. Soon all of these need to invest in brand new particle measuring equipement. And he has developed his own instrument again.  After I left the merchant navy I worked for a company dealing in industrial automation and analytical instruments. We used to supply environmental (ambient and stack) analytical measuring systems. So I am a little familiar with some of these systems, although technology has come a long way since. I asked Leo about an affordable exhaust emission analyser. He will check, he thought he might have something for me second hand. All in all, a very interesting afternoon. Learned a lot of new stuff. Really interesting to hear Leo talk very passionately about the business he has build. Extremely nice he is helping out with our meter. To be continued! Jeroen | |

| |  (10)

Thanks (10)

Thanks

|

| The following 10 BHPians Thank Jeroen for this useful post: | digitalnirvana, keroo1099, Shubhendra, Sutripta, Tgo, Thad E Ginathom, vaasu, vishy76, VivekCherian, wbd8779 |

| | #489 |

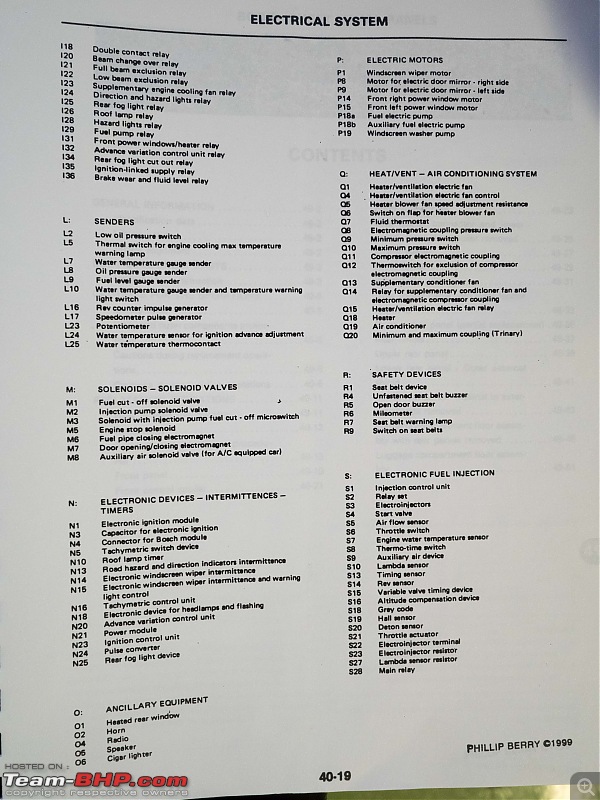

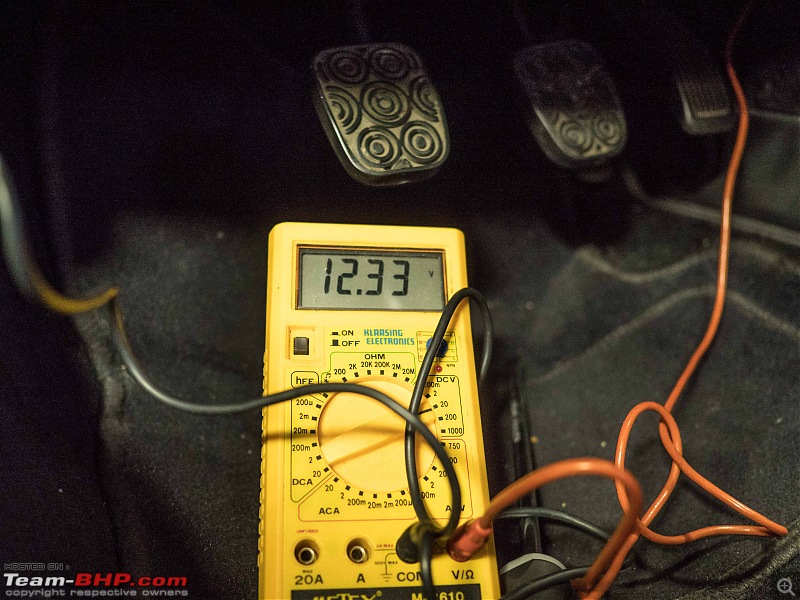

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp A couple of quick jobs this evening. First I had a look at the door catch of the passenger door of the Spider. It felt very stiff. Remember, I replaced it not too long ago, because it had broken. And it was a hell of a job. Don’t want to have to do that again. See: https://www.team-bhp.com/forum/diy-d...ml#post4484996  So out comes the various mirrors and my trusted little scope to see what is what.  But just about impossible to see. I decided to just spray some teflon spray on it. Certainly did the trick. Onto the next job on the Spider; The door handle on the driver door, when you pull it to open the door, won’t return back to its normal position  First things first; you will never ever hear me complain about my garage. But sometimes it can be a bit tight. too many mishaps on the various cars last year. So making sure, I don’t damage anything.  The door cards comes off easily. I have done this many times. This door card is a bit of a special case. It never fitted properly, so I might have a go at that too.   It is just impossible to get a good view of the various levers, linkages and so between the inside door handle and the actual door lock/Catch. My money is on the mechanism of the door handle itself being a bit stiff. Getting some teflon spray on it proved difficult. I tried to make some nozzles with some heat shrink!  Not very successful, although definitely some improvement. This weekend has nice classic car show in Antwerp. I will definitely have to go, to buy something that will allow me to spray teflon spray around several corners/bends. (As if I needed an excuse to go) I also investigated the problem with the heater blower fan. It does not turn. Fist thing, check the wiring diagram:   As the window wipers were working fine, it meant that the fuse and the main power supply was ok. So I dived underneath the dashboard with my multimeter. 12 V on the terminal to the electric motor of the fan.  With the help of a very long screwdriver and by standing up side down in the foot well, I can just see the fan blade through the bottom air outlet duct. I can turn, but it has a lot of resistance. That is almost certainly a seized bearing! Not good. As you might recall, my Spider stood outside Goof’s workshop during some of the engine revision. It was very rainy in that period. It already proved problematic for the rear lights. A few posts back I showed how water had gotten into them. Water finding its way to the bottom of the fan is a known problem on these Spider (and all Alfa 105 Series). I know in theory you should be able to get the fan out from underneath the dashboard. It means removing some of the panel on the transmission tunnel. The fan and motor is kept in place by four little nuts. If you can get access, if those nuts are not seized, it should work. If I can not get those nuts off, it is going to be almost impossible without having to removing the complete dashboard.  Fingers crossed!! I might just try spraying a lot of WD40 into the fan outlet and hope it settles at the bottom. Last little job, was fixing one of my tools; My Bosch electric screw driver. I bought it a little over two years when we just bought our new home and I knew I needed a new electric screw driver. It has seen an awful lot of use and till date I was still happy with it. That was until last night. I had gone across to our daughter. She is pregnant with her first baby and our first grand child. So the baby room needs to made ready. We had bought various things at the local Ikea. Which means some assembly was required. For some reason my electric screwdriver started playing up. Often, it would not start if I pulled the trigger with it pointing downward. Never, when I held it horizontally. Usually a shake or a light tap meant it got going again. The power setting or turning direction did not make any difference. Only the position in which I held.  I am not sure if it still under warranty, but even so, I could not find the receipt. So I decided to open it up  I must say, I was pleasantly surprised how well this thing has been designed and manufactured. It reminds me of my W123. You can take it apart easily and just as easily everything can be put back together again. German Grundllichheit as they say. Because it would only not work intermittently in the vertical position, my thought was something might be loose, or near loose. I checked all the bits, pulled at all the wires, connectors etc. And sure enough, it looks as if one of the connectors was not properly secured.  Put everything back together and it seems fine. I probably won’t know until the next Ikea piece of furniture will need assembling. Although I have not (yet) bought a lathe, I have enrolled in a course. It is more than 30 years, since I last used one. So I found myself a nice course. Maximum 4 students to one teacher, a full day, just re-familiarisation of the basics. The course is given at the Leidse Instrumentmaker school. Not sure how that translate, but you probably get the idea. This is a specialised school that trains people in all kinds of machining and various techniques for making small parts for various machinery, laboratory etc. Perfect for me. Looking forward to it, April 6th. Must get my lathe before though. Jeroen Last edited by ajmat : 6th March 2020 at 09:30. Reason: minor typo |

| |  (4)

Thanks (4)

Thanks

|

| The following 4 BHPians Thank Jeroen for this useful post: | digitalnirvana, Tgo, Thad E Ginathom, vaasu |

| | #490 |

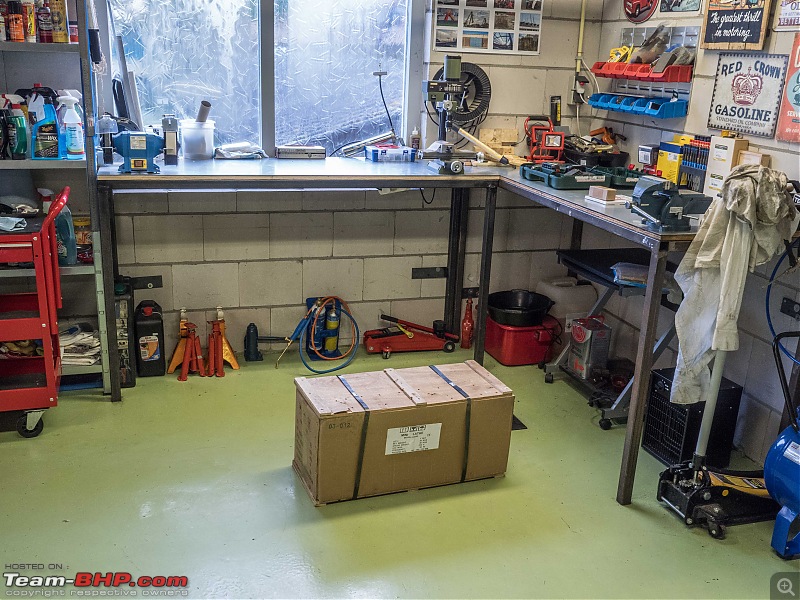

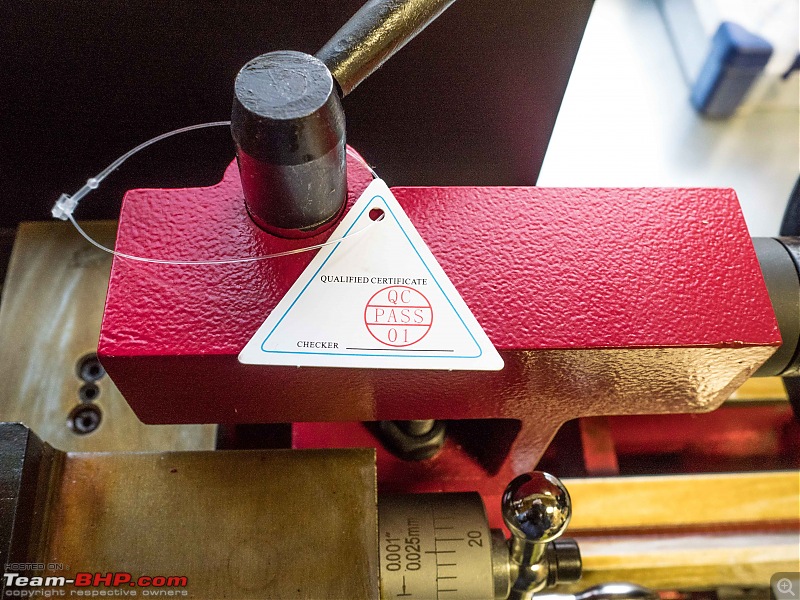

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp This morning I realised that I have been looking at and wanting to order a lathe that is manufactured in China. What with the virus, stocks here in the Netherlands will be running low. I visited my favourite tool shop HBM just over a week ago. Nearly all their tools come from China. And shelves were beginning to show empty spots. It is supposed to be my wifeís present for me as my birthday is next week. She is abroad for a few weeks and I thought I would wait ordering until she gets back. So I decided to just go ahead and order it. Picked it up this afternoon after work. I bought it from a little webshop. The guy basically runs it out of his garage, as a sort of hobby. I had visited him a few weeks ago, just to have a good look at it. It comes in a sturdy box:  Unboxing:  All sorts of bits, some still need attaching to the lathe.  Here we are! Just sitting on my workbench. I will need to mount it properly. Also, it is covered in conversation oil. I need to clean it properly and rub some machine oil on it.  This is an original(?!) Sieg lathe. You canít go wrong with Chinese quality control!  But seriously, I have spend quite a bit of time on various forums, checking opinions and references on a large variety of lathes. Actually, many look very similar, because most come from China these days and from the same factories most likely too. So the differences are small, but the prices can still vary greatly. Anyway, I found plenty of people who were quite pleased with this little machine. Also, Frank Hoose has done a very extensive 8 part review of this very little machine. His website is quite the treasure trove if you ever want to know something about turning and or milling: http://www.mini-lathe.com/Default.htm I need to get a few more bits to really get going, but first job will be cleaning, oiling and mounting. Hope to get this done in the next week or so Jeroen Last edited by Jeroen : 6th March 2020 at 23:33. |

| |  (5)

Thanks (5)

Thanks

|

| The following 5 BHPians Thank Jeroen for this useful post: | ashis89, digitalnirvana, Jaguar, keroo1099, Thad E Ginathom |

| | #491 |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,259

Thanked: 28,606 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Congratulations on the purchase of your new lathe! It seems that those Chinese minilathes come in wide range of quality. I was watching part of a rebuild series only a week or two ago (adventures with a very small lathe --- I think). It looks like dissambly and clean up is fairly vital --- removal of general crud and grinding dust that would make the life of the mating surfaces short. For you, I'd think that such an exercise would be fairly trivial, and even fun! You've obviously been exploring the net for such material, and may well already know my favourite machinists! For a European (German) at work (No amateur: it's his day job too) do have a look at Stefan Gotteswinter's channel. I'm so envious! I guess I afford a Chinese mini-lathe if I decided to. What I do not have is the space to use it. Inflicting machine tools on my wife is a non-starter. Cats has been bad enough!  Last edited by Thad E Ginathom : 7th March 2020 at 02:04. |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Thad E Ginathom for this useful post: | Jeroen |

| |

| | #492 | |

| Senior - BHPian Join Date: Jul 2009 Location: Calcutta

Posts: 4,668

Thanked: 6,228 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

Regards Sutripta Last edited by Sutripta : 8th March 2020 at 13:07. | |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Sutripta for this useful post: | Jeroen |

| | #493 | |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

Jeroen | |

| |  ()

Thanks ()

Thanks

|

| | #494 |

| Senior - BHPian Join Date: Jul 2009 Location: Calcutta

Posts: 4,668

Thanked: 6,228 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp ^^^ I feel you would have been happier with a preowned Myford or Schaublin mechanical. My choice would have been the Hobbymat (Made in GDR), but very importantly, with all accessories. The Sieg will certainly do odds and ends. But I doubt you'll have pride of ownership, or the satisfaction of operating a finely crafted precision machine tool with your own hands. (Before the machinists here tear me to shreds for saying the Myfords etc are the W123 of lathes, those most certainly are not. But also certainly are a couple of levels above the Siegs) Regards Sutripta PS - Just as an aside, could you find out how much a Weiler 8" (fully mechanical lathe) costs there new. And what is its reputation. Interested in knowing because (I think) it is a superb lathe, and made here in India. One of the Colchesters is also made here in India, but I think the Weiler is a class above. Last edited by Sutripta : 8th March 2020 at 23:31. |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank Sutripta for this useful post: | digitalnirvana, Jeroen, Thad E Ginathom |

| | #495 |

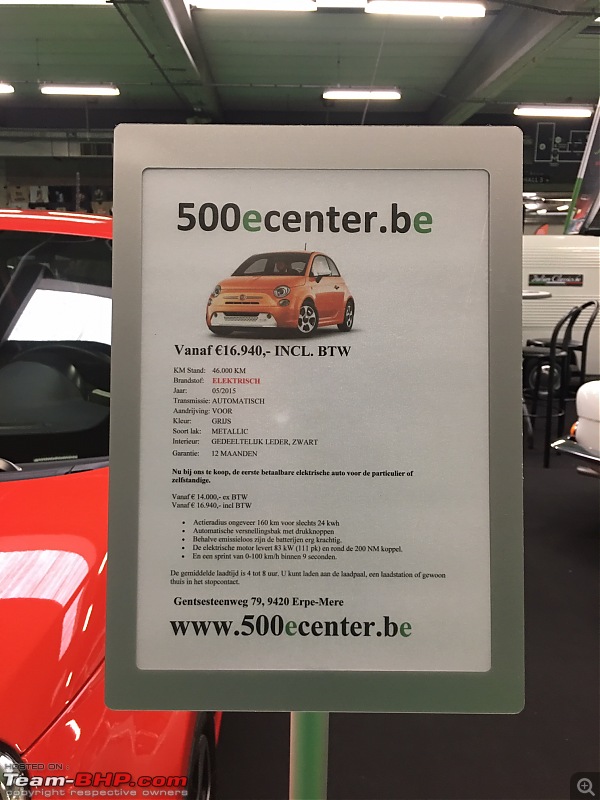

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp We have had an awful winter here in the Netherlands. We have had months of wet and windy weather. No snow, virtually no frost. Just endless wind and rain. Yesterday, Saturday, at long last a nice, sunny and dry day. So I spend most of my time out on my bicycle, enjoying the sun!. By the time I got home, it was still early, so I changed quickly and got the Mercedes out for a little tour. My wife is abroad visiting her mum in Barbados, so I can whatever I want to. She does not do the biking, but she does enjoy touring in any of our cars. We are so fortunate with our home in this gorgeous part of the Netherlands. This area is known as “Rivierenland” (Land of the many rivers). Which means in the Netherlands, endless little ferries, or pontjes as we call them. Here I am waiting for one:  This is on the pontje, cars, bikes, bicycles, people making the most of this nice weather  This is a so calling “swing-ferry”. It is tether to a wire, sprung across a couple of little boats, in the middle of the river. The skipper can move the orientation of the ferry to the current. So it is the actual current pushing the ferry across!  These days, these ferries do have a little engine and propellor, but they are still using the river current too. Have a look at this little video. Same river, different pontje, about 10 kilometers upstream from where I crossed: Next day, Sunday, was back to the usual awful weather. Rain and windy. But as luck would have it, a classic car show to attend. The Antwerp Classic Car Salon. I have been there several times over the years, so just a few images for an impression; This lady was looking very smart in her period dress  Any classic car show and there will be a bunch of E-types  Trip down memory lane. I had one of these, many years ago as a company car  Not just cars   Had a bit of chat with the guy offering (new) Royal Enfields: He had a whole range of them. They sell for about Euro 4500 - 5000, which is about double from India I would think?  These days, there are all sorts of bicycles, not just your ordinary run of the mill bicycles, what do you think? Not my style though.  We have a thread on the new Electrical Fiat 500. I posted there as well. Nothing new under the sun really. Fiat developed an electrical 500 a decade ago. Purely for the Californian market. But those are now making their way back to Europe and are being sold second hand.    Any car show will have endless market stalls with endless model cars. I liked this one, very detailled model. And I will admit, it is probably the only car in the world, I would not have a clue on how to fix. I mean, where does one start on a flux capacitor?  I have always had a weak spot for the Toyota land cruiser. I have driven them extensively in Africa, mainly Gabon. I know the Landrover has the reputation of being the ultimate off roader. But trust me, if you find yourself in real offroad territory, go for the Toyota. Landrovers suck big time when it comes to reliability out there in the woods, deserts, etc. These days, classic Landcruisers like this one are worth a fortune.  Those that have followed my various classic car event post know the Dino is my favourite Ferrari!  Some more quite rare cars, Italian and British, spot the difference in styling  I am not into American Classics. But I will admit they are a sight to behold. Look at this engine:  I also spend an hour or so at the stand of my own club; Alfa Romeo Spider Register. Always good to catch up with everybody and coffee is for free!  I bought a few things (as I usually do). You will see in the next post. Jeroen Last edited by Jeroen : 8th March 2020 at 23:20. |

| |  (4)

Thanks (4)

Thanks

|

| The following 4 BHPians Thank Jeroen for this useful post: | ashis89, digitalnirvana, R2D2, Thad E Ginathom |

|