Quote:

Originally Posted by aspire  Comparing navigating on seas with driving on Mumbai traffic, The way Jeremy was asking questions to the captain, seemed a bit racist to me to be honest. I am sure it takes immense skill and expertise to captain this ship.

This ship was managed by Wallems at one point of time right? |

@ aspire, while watching the video it seemed that Jeremy was surprised that the Indian Captain could navigate a vessel of this size at sea and does make a snide comment about driving in India.

With regard to Wallems managing this vessel, I am sorry I do not know this answer.

Quote:

Originally Posted by V.Narayan  Ithaca, thank you for sharing. The size and immenseness boggles the mind. |

@ V.Narayan sir, I will answer your queries below in separate sections.

The Jahre Viking is a ULCC - Ultra Large Crude Carrier.

Most vessels of that size are currently a tad smaller and called VLCC - Very Large Crude Carrier.

SCI has a few ULCC - Desh Ujala, Desh Vaibhav, Desh Viraat & Desh Vishal.

Tell us about fuel burn

Most VLCCs will consume roughly 100 ~ 120 MT of Heavy Fuel oil a day doing a sailing speed of 12 - 14 knots per hour at 70~75 rpm . (1 nautical mile = 1.852 kilometers). This translates into a sailing distance of 288 to 330 nautical miles per day.

This consumption will vary on whether the vessel is in ballast or fully laden. Weather conditions also can lead to increased consumption.

Typically Total Fuel Tank (called Bunker Tanks) Capacity would be roughly 6000 to 8000 MT for Heavy Fuel Oil spread out over four tanks.

Marine Diesel will have her own separate bunker tanks.

weight & size of the propeller

Will find out this answer and get back.

The attached sheet has made a mistake on the propeller size though.

Cannot be 1000 meters diameter, should be 100 meters instead.

engine size

Typical engine sizes for a VLCC would range from 6 to 12 cylinder engine with a bore diameter of 800 mm to 1200 mm.

Engine in the attached sheet - Hyundai – B&W 6S90MC - is a 6 cylinder, Super long stroked engine having a cylinder bore of 90 cm or 900 mm.

The power output would be in the range of 32000 bhp and above.

The pdf I have attached to this post shows the engine power as kW and not BHP.

BHP = 1.36 x kW (Approx)

how many on the bridge at a time

During the sea watches, it is mandatory to have two watch keepers at all times on bridge whose only duty is to keep watch to ensure vessel is following her course and there is no traffic to attend to.

This will include the watch keeping officer and his lookout who is a certified Able Bodied Seaman. At no time is the Bridge allowed to be unmanned.

Modern vessels have an bridge alarm system. Motion Sensors are fitted at various parts of the bridge and lead to a command box which has a timer unit. Timer is set by master - usually 15 minutes - and the watchkeepers on bridge during watch have to activate any sensor to reset it to 0.00 sec.

If not an alarm is sounded in the Captain's cabin and deck officers cabins, smoke rooms and dining rooms to alert staff that the bridge is unmanned.

The chief officer who keeps the 0400 to 0800 & 1600 - 2000 watch will always have a cadet with him along with his own AB. The cadet uses this time to learn from chief officer.

During passages in congested waters, shallow patches or in heavy traffic areas like the English Channel, Hormuz Straits or Singapore straits, the Captain is always on bridge and he is assisted by his duty officers and duty lookouts as per the watch schedule at that time.

does the ship bend and warp

Hogging and sagging are typical for vessels this long. The structure also gets affected due to variations in temperature that the vessel has to endure during its life cycle. It could be up at Alaska in the winters today and two months later could be steaming down the Persian Gulf. Design of ships take into account expansion of plates and piping to counter hogging and sagging.

how do you navigate inside the ship-getting lost can be a problem

The area we live in is called the accommodation and is the superstructure in the aft of the vessel.

Consider it like an apartment that is typically 4 to 6 stories high.

This houses the bridge, Officer & Crew accommodations, dining areas, recreation areas, gym, the cooking area - galley, stores for provisions + deck spares + electrical spares + engine stores, Ships office, Master's Office, Chief Engineer's Office, Radio Room.

Most ships that I have sailed on if they had more than 4 floors above, they would have an elevator going from the Engine Control room to the Bridge since climbing a total of 8 to 9 floors is not an easy task day in day out.

Entrance to each floor (Deck in naval speak) has the layout of that particular floor & ranks of the occupants or name of the various cabins that occupy that floor so navigating within the deck is easy.

From the accommodation superstructure we access the engine room from within the accommodation.

Typical engine rooms too will be 4 to 6 floors deep.

Within the first day, most seafarers get the general layout of their vessel since it is usually a repetition of their previous vessels.

First timers / Non Ship staff tend to get confused so are usually always accompanied by ship staff.

is the shaft ever removed for maintenance or does it stay in place through the life of the ship. etc.

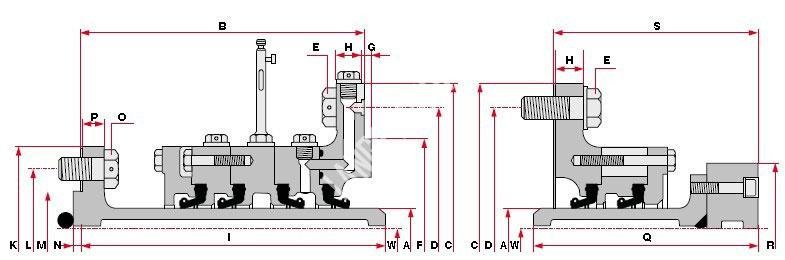

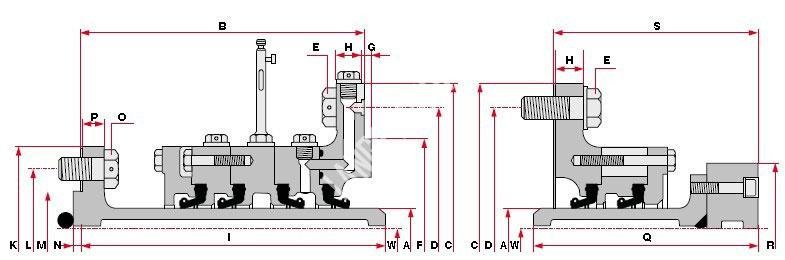

The main engine is connected to the propeller via shafting that would typically consist of one or more intermediate shafts.

Each intermediate shaft is balanced by its own Intermediate Shaft bearing.

It exits the engine room via the stern tube and is connected to the propeller on the outside.

Stern Tube is an oil filled tube that is seated in a water chamber with oil seals on either end to prevent oil from leaking into the sea or allowing salty sea water enter the stern tube. These seals harden over time and need replacement. Hence the shafting has to be extracted once in 5 years for inspection and seal renewal.

Typically a vessel has to enter dry dock twice every 5 years. The 5 year cycle is the major drydock and the 2.5 year interval drydock is the intermediate drydock. Nowadays due to cost cutting the vessel stays inside a drydock for the most minimal time to get her hull cleaned and painted. It is during its stay at the drydock that the shafting is removed.

Attached:

1. specs.pfd (VLCC NEW BROCHURE)

Propeller Shafting - Typical Layout

Oil Seals

(2)

Thanks

(2)

Thanks

(4)

Thanks

(4)

Thanks

(1)

Thanks

(1)

Thanks

(3)

Thanks

(3)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(6)

Thanks

(6)

Thanks

(4)

Thanks

(4)

Thanks

(6)

Thanks

(6)

Thanks

(3)

Thanks

(3)

Thanks

(2)

Thanks

(2)

Thanks

(5)

Thanks

(5)

Thanks

.

.